MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

120 VAC PTFE 45 Degree Elbow Heater Jackets

Overview

- Compatible with ISO and Buttweld 45 elbows

- PTFE heater with Teflon woven shell

- 100-120 VAC power requirement

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 1.5 in. Diameter Tubing, 120V

$749

5 Weeks

|

494015162-1150 Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 1.5 in. Diameter Tubing, 120V |

5 Weeks

|

$749 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits ISO 90 Degree Long Elbow, 1.5 in. Tubing, 240V

$968

5 Weeks

|

494015263-1150 Heater Jacket, PTFE-Teflon®, fits ISO 90 Degree Long Elbow, 1.5 in. Tubing, 240V |

5 Weeks

|

$968 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 1.7 in. Diameter Tubing, 120V

$762

5 Weeks

|

494017162-1150 Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 1.7 in. Diameter Tubing, 120V |

5 Weeks

|

$762 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.0 in. Tubing, 120V

$768

5 Weeks

|

494020160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.0 in. Tubing, 120V |

5 Weeks

|

$768 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits ISO-KF 45 Degree Elbow, 2 in. OD Tube, 120V

$780

5 Weeks

|

494020162-1150 Heater Jacket, PTFE-Teflon®, fits ISO-KF 45 Degree Elbow, 2 in. OD Tube, 120V |

5 Weeks

|

$780 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 2 in. OD Tube, 120V

$780

5 Weeks

|

494020164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 2 in. OD Tube, 120V |

5 Weeks

|

$780 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 2 in. OD Tube, 120V

$810

5 Weeks

|

494020165-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 2 in. OD Tube, 120V |

5 Weeks

|

$810 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.4 in. Tubing, 120V

$810

5 Weeks

|

494024160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.4 in. Tubing, 120V |

5 Weeks

|

$810 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.5 in. Tubing, 120V

$823

5 Weeks

|

494025160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 2.5 in. Tubing, 120V |

5 Weeks

|

$823 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 2.5 in. OD Tube, 120V

$866

5 Weeks

|

494025164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 2.5 in. OD Tube, 120V |

5 Weeks

|

$866 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 3.0 in. Tubing, 120V

$909

5 Weeks

|

494030160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 3.0 in. Tubing, 120V |

5 Weeks

|

$909 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits ISO-MF 45 Degree Elbow, 3 in. OD Tube, 120V

$924

5 Weeks

|

494030162-1150 Heater Jacket, PTFE-Teflon®, fits ISO-MF 45 Degree Elbow, 3 in. OD Tube, 120V |

5 Weeks

|

$924 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 3 in. OD Tube, 120V

$924

5 Weeks

|

494030164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 3 in. OD Tube, 120V |

5 Weeks

|

$924 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 3 in. OD Tube, 120V

$924

5 Weeks

|

494030165-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 3 in. OD Tube, 120V |

5 Weeks

|

$924 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits 3.31 in. Long Bellows, 1.5 in. Diameter Tubing, 240V

$957

5 Weeks

|

494035160-1150 Heater Jacket, PTFE-Teflon®, fits 3.31 in. Long Bellows, 1.5 in. Diameter Tubing, 240V |

5 Weeks

|

$957 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 3.5 in. Diameter Piping, 120V

$981

5 Weeks

|

494035164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 3.5 in. Diameter Piping, 120V |

5 Weeks

|

$981 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 4.0 in. Tubing, 120V

$1,005

5 Weeks

|

494040160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 4.0 in. Tubing, 120V |

5 Weeks

|

$1,005 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 4 in. OD Tubing, 120V

$1,059

5 Weeks

|

494040162-1150 Heater Jacket, PTFE-Teflon®, fits ISO 45 Degree Elbow, 4 in. OD Tubing, 120V |

5 Weeks

|

$1,059 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 4 in. OD Tube, 120V

$1,035

5 Weeks

|

494040164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 4 in. OD Tube, 120V |

5 Weeks

|

$1,035 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 4 in. OD Tube, 120V

$1,035

5 Weeks

|

494040165-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Elbow with Tangents, 4 in. OD Tube, 120V |

5 Weeks

|

$1,035 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 4.5 in. Tubing, 120V

$1,059

6 Weeks

|

494045160-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow with Flange on one side, 4.5 in. Tubing, 120V |

6 Weeks

|

$1,059 |

|

||

|

Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 4.5 in. Diameter Piping, 120V

$1,089

6 Weeks

|

494045164-1150 Heater Jacket, PTFE-Teflon®, fits Weld 45 Degree Elbow, 4.5 in. Diameter Piping, 120V |

6 Weeks

|

$1,089 |

|

Specifications

-

SeriesSeries 49

-

TypeHeater Jacket

-

Insulation MaterialPTFE Teflon-Woven

-

Component TypeElbow

-

For Use WithSee order table

-

Temperature Range35 - 200°C

-

Pre-Set Temperature150°C Standard

-

Voltage Requirements100-120 VAC

-

Heater ConnectorsCircular 6 Contact Locking Bayonet

-

Housing MaterialsController: Injection Molded

-

Controller DimensionsØ2.2 in. x 3.7 in.

-

Operating Temperature0° to 60°C

-

ComplianceCE, SEMI S2

Features

PTFE Teflon®-Woven Heater Material

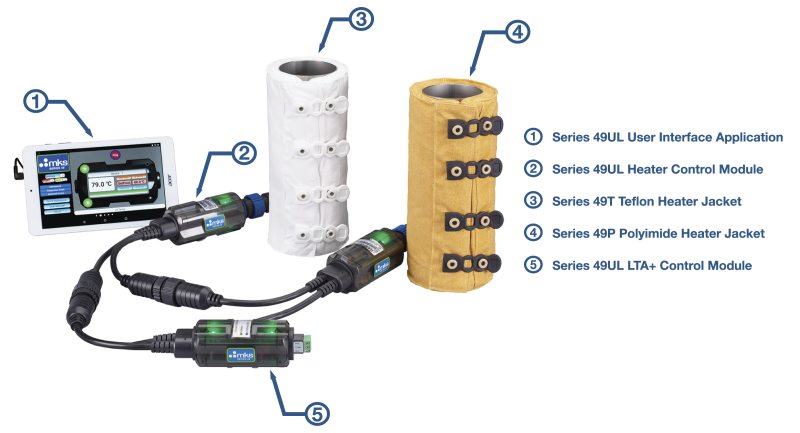

Series 49UL heater jackets provide maximum performance, utilizing a proprietary Teflon woven shell achieving ultra low particulate generation, preventing surface contamination. This low outgassing product is ideal for customers that need low Volatile Organic Compound (VOC) in the work area. These heaters are constructed with fully squared ends and a shape to provide maximum energy efficiency and thermal uniformity. The patented automated sewing of the heater element safely secures it to the reinforced inner materials thus resulting in superior uniformity and guaranteed temperature profiles for the life of the heater. PTFE heaters are generally used in critical applications where elevated temperatures (up to 200°C), and low VOCs are required.

Significant Energy Savings

S49UL Thermal Management Systems provide greater energy savings and efficiency over competitive heater products. The new thermally efficient advanced Polyimide and PTFE materials used in the heater jacket construction provide superior insulation.

The system also offers a Standby Mode which can be used during preventative maintenance cycles, allowing for a reduction in energy consumption while minimizing heat-up and restart time.

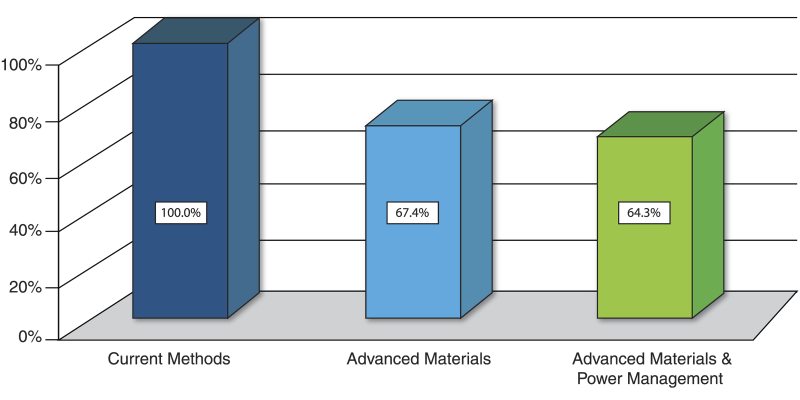

This chart the energy use of the S49UL system to other heater solutions. Preventative maintenance cycles combined with our advanced materials resulted in 35% less power usage compared to other common heater products.

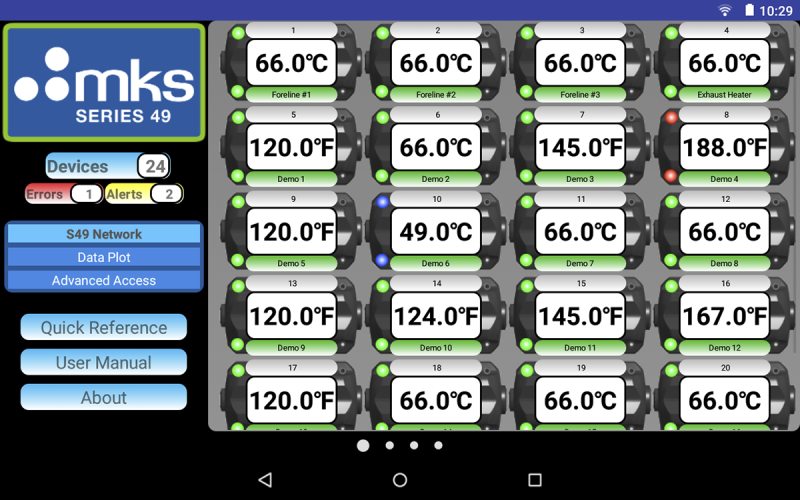

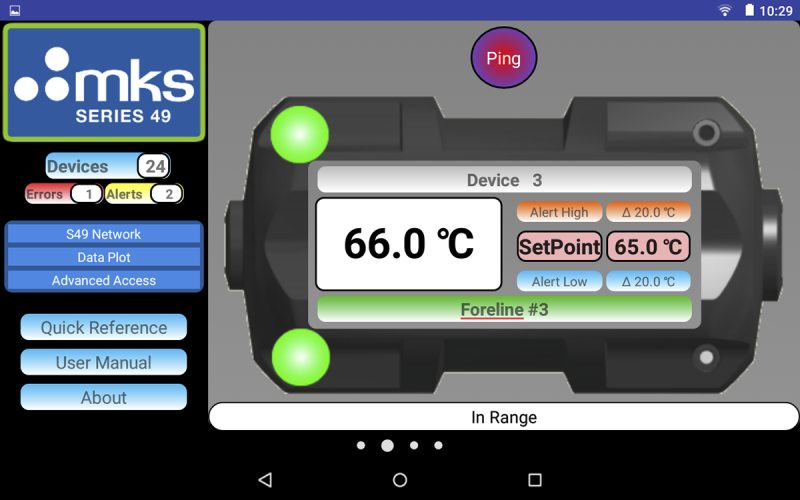

Intuitive Advanced Temperature Control

S49UL Thermal Management Systems feature an innovative, automatic, self-addressing function for configuration of the controller network. Upon connection, the Tablet App or LTA+ Controller automatically identifies networked controllers and sets individual device addresses, configuring the communication network. The user interface system allows access to system settings and functions via Modbus RTU communications over serial RS485. Commands can be sent to individual heater controllers or broadcast to the entire heater network.

Series 49 Controller Technology

The Series 49UL controller uses custom interconnects that allow the controller to be disconnected from the heater jacket. This feature provides flexibility in system configuration and simplifies maintenance and replacement.

The Series 49UL controller can be configured and customized using the optional Tablet Application. The user interface application is the gateway to a comprehensive thermal management control system providing access to temperature limits, setpoints, data and network alerts.

For user-provided communications systems, the S49UL controller is RS485 Modbus RTU ready. The S49UL User Manual provides details on communications access, register definitions, and control configuration.

Advanced Digital Communications

The S49UL User Interface System enables an integrated remote communications and diagnostics solution for the S49UL Thermal Management System. The user-friendly system allows quick and easy set up and operation with a downloadable Android-based tablet software application.

User Interface System

Connecting to the heater network the user interface initiates an auto-addressing sequence which automatically sets the address of the heater controllers on the network. The S49UL software provides access to all functions of the S49UL heater control system. The application provides intuitive system control set up, monitoring, diagnostics, and parameter adjustments, creating a user-friendly experience.

The User Interface allows direct access to variables such as temperature set points, upper and lower temperature threshold alarms, and error conditions. For more advanced users, the system offers password protected access to detailed control and safety parameter settings.

Data Plot Screen

data plot screen on the Series 49UL User Interface

The data plot screen on the Series 49UL User Interface enables plotting selected heaters with adjustable timescale.

Heater Jacket Applications

Semiconductor

- ETCH

- Prevent solidification of aluminum chloride (AlCl3) in an aluminum etching system

- CVD, PECVD, MOCVD, LPCVD (Nitride and TEOS)

- Prevent solidification of ammonium chloride (NH4Cl) in a silicon nitride LPCVD system

- Reduce solid buildup in other semiconductor processes, such as titanium nitride, tungsten, and TEOS CVD

- EPI (Epitaxy)

- ALD

- Gauge Trees

- Maintain uniform temperature environments in complex shapes

- Gas Analyzers, Endpoint Detectors, Bubbler Cylinders, Mass Flow Controllers, Manometers, Isolation and Butterfly Valves

Analytical Instrumentation

- Mass Spectrometers

- Evaporators

- Chambers

Industrial Coating

- Solar Substrate Processing

- Thin Films

- LED Manufacturing

Custom and R&D Applications

- Heaters for custom and R&D applications can be engineered to meet specific requirements

Accessories

Resources

Literature

- Series 49UL Thermal Management System (2.4 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity