Application Notes

Filter by:

Application Notes

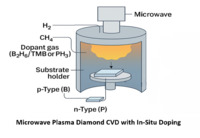

CVD Diamond for Next-level Performance in Semiconductor Applications

Microwave Plasma Chemical Vapor Deposition (MPCVD) enables precise control of diamond purity, structure, and doping—accelerating adoption across advanced semiconductor, RF, …

Application Notes

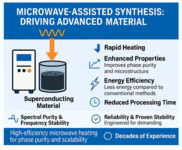

Accelerating Superconducting Material Synthesis with Microwaves

Microwave-assisted synthesis is transforming superconducting material processing by enabling volumetric energy transfer and non-equilibrium reaction pathways that conventional technologies …

Application Notes

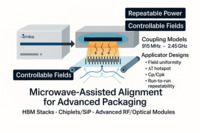

Orientation by Design: Precision Nanostructure Alignment for Advanced Packaging

MKS introduces microwave-assisted nanostructure alignment, a manufacturing technique that integrates engineered anisotropy directly into high-volume advanced packaging production …

Application Notes

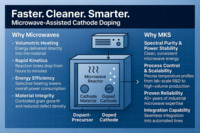

Microwave-Assisted Cathode Doping: Faster. Cleaner. Smarter.

Microwave-assisted doping provides a high-efficiency alternative, transforming cathode synthesis from a bottleneck into a strategic advantage.

Application Notes

Microwave: A Breakthrough for Sustainable Battery Material Manufacturing

Conventional battery material production carries significant environmental and operational costs. Microwave technology offers a cleaner, faster, and more efficient alt …

Application Notes

Single-Crystal Diamond Wafers: Redefining Semiconductor Performance

As the demand for faster, more efficient, and sustainable electronics accelerates, the industry faces critical challenges regarding heat management and power density.

Application Notes

Microwave Generators for Advanced Thin Film Deposition

In high-throughput manufacturing across semiconductors, photovoltaics, display technologies, and advanced surface engineering, microwave energy is the critical factor for …

Application Notes

Microwave Technology: The Strategic Enabler for Next-Generation AI Semiconductor Manufacturing

Microwave technology is increasingly crucial in meeting these stringent demands, facilitating ultra-clean surfaces, high-precision etching, and advanced packaging techniques …

Application Notes

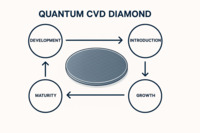

Diamond: The Quantum-Era Material Powered by Microwave Plasma Chemical Vapor Deposition (MPCVD)

In the race to redefine what is possible in quantum sensing, photonics, and power electronics, a new game-changing material has emerged: diamond, meticulously grown via Microwave …

Application Notes

Microwave-Assisted Processing for Advanced Semiconductor Nodes

Conventional thermal budgets and process controls face severe constraints. Microwave-assisted processing (MAP) is emerging as a critical technology, offering a path forward for advanced …

Application Notes

Microwaves: Driving the Next Leap in Semiconductor Scaling

Microwave technology is no longer a niche tool—it is emerging as a critical enabler for success at the most advanced semiconductor nodes.

Application Notes

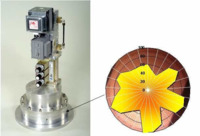

Enhancing Surface Engineering: The Case for Microwave Plasma Coating

Plasma coating with microwave energy offers significant advantages over conventional methods, generating high-density, electrode-free plasma, which ensures rapid, uniform, and …

Application Notes

Unlocking Precision and Yield with MKS Microwave Plasma Etching

Traditional etching methods in advanced semiconductor manufacturing often introduce damage, compromise device integrity, and limit yield. Microwave Plasma Etching is …

Application Notes

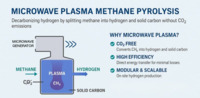

Microwave Plasma Methane Pyrolysis: The Future of Hydrogen

Turquoise hydrogen, produced by splitting methane into H2 and solid carbon without CO2 emissions, is emerging as a critical net-zero solution, and Microwave Plasma Methane Pyrolysis …

Application Notes

Microwave Technology: Powering the Green Industrial Transition

As global industries accelerate the shift toward sustainability and decarbonization, MKS is at the forefront, leveraging advanced microwave technology to …

Application Notes

Microwave Technology in Next-Gen Semiconductor Fabrication

As device geometries shrink to angstrom levels and the materials landscape diversifies (including compound semiconductors like SiC and GaN), semiconductor …

Application Notes

Microwave Plasma: Transforming ALD in Semiconductor Manufacturing

Microwave plasma holds an established role in surface engineering, yet its unique properties position it as a potentially transformative technology for semiconductor manufacturing, …

Application Notes

CVD Diamond for Quantum Tech: Powered by MKS Precision

Quantum innovation relies on materials with atomic-level precision, and Chemical Vapor Deposition (CVD) diamond is at the forefront of delivering this. Its unique ability to host …

Application Notes

Power-to-X Decarbonization via Microwave Plasma Technology

As industries worldwide accelerate their transition to net-zero, Power-to-X (P2X) technologies are emerging as a critical component for converting renewable electricity into valuable …

Application Notes

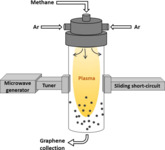

Microwave Plasma: Driving Scalable, High-Quality Graphene Production

Graphene is a groundbreaking material with exceptional properties, including high electron mobility, thermal conductivity, and mechanical strength. For applications ranging from …

Ultra-High Velocity

Ultra-High Velocity