MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

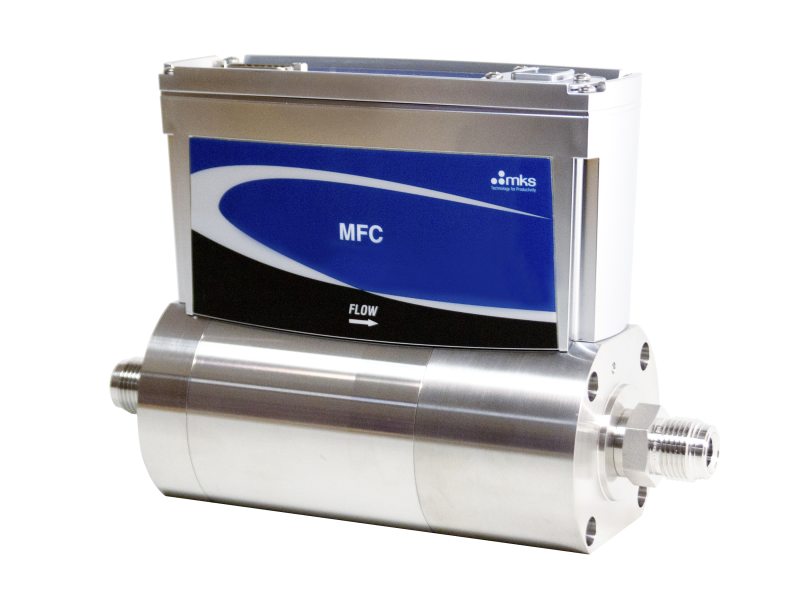

IP66 Rated Multi-gas, Multi-range Elastomer-sealed 500-1000 slm Mass Flow Controllers

Overview

The IE1000A mass flow controller is elastomer-sealed, multi-gas/multi-range MFC with an IP66-rated enclosure designed for use in harsh industrial environments where resistance to liquid and dust ingress are essential. The IE1000A is capable of Full Scale ranges from 501 to 1000 slm (N2 equivalent). This broad flow range is enabled by the unique control valve design, which responds rapidly to set point changes while maintaining closed conductance leak rates that are well below other high flow mass flow controllers.

- Flow rates from 500 to 1000 slm

- Seal and valve plug option of Viton, Buna, Neoprene or EPDM

- Analog, RS485, Profibus™, or DeviceNet™ I/O

- Standard closed conductance leak rate of less than 1.0% of Full Scale

- 1 to 2 second settling time

Products

Configuration Options

The following options are available for IE1000A IP66-rated, Elastomer-sealed 500-1000 slm Mass Flow Controllers

Ordering Code Example: IE1000A013255T4R0020

|

Configuration Option |

Option Code |

|---|---|

| IE1000A Mass Flow Controller | IE1000A |

Gas (Per Semi Standard E52-0703) |

|

| Helium (He): 700-1400 slm | 001 |

| Argon (Ar): 450-900 slm | 004 |

| Hydrogen (H2): 500-1000 slm | 007 |

| Nitrogen (N2): 500-1000 slm | 013 |

| Other Gas Options | See Here |

Flow Range Full Scale |

|

| 1000 slm (1,000,000 sccm) | 106 |

Fittings (compatible with) |

|

| 12 mm Swagelok | L |

| 0.5 in. tube compression | S |

| 0.75 in. compression | Z |

| 0.5 in. NPT female | M |

| 0.75 in. NPT female | N |

| 8 VCR male | T |

| 8 VCO male | D |

Connector |

|

| Profibus | 4 |

| PROFINET | 9 |

| 15 pin D (Analog 0-5 VDC I/O) | B |

| 15 pin D (4-20 mA I/O) | G |

Seal Materials |

|

| Viton® | V |

| Buna | B |

| Neoprene® | N |

| EPDM | E |

Valve/Device Type |

|

| Normally closed | 0 |

| Mass Flow Meter | 3 |

Firmware |

|

| MKS will ship firmware revision current to date | 20 |

* For gases not listed in the standard products gas table, please contact the MKS applications department for assistance.

** The Full Scale flow rate is designated by a 3 digit number. The first two digits represent the significant digits of the Full Scale flow rate separated by a decimal point. The third digit is the exponent of the power of ten. Example flow rate code: 255 is 2.5 x 105 sccm or 250 slm; 105 is 1.0 x 105 sccm or 100 slm

Specifications

-

TypeMass Flow Controller

-

Full Scale Flow Range501-1000 slm (N2 equivalent)

-

Fitting TypeCompatible with:

12 mm Swagelok

0.5 in. tube compression

0.75 in. compression

0.5 in. NPT female

0.75 in. NPT female

8 VCR male

8 VCO male -

ConnectorProfibus

PROFINET

15 pin D (Analog 0-5 VDC I/O)

15 pin D (4-20 mA I/O) -

Maximum Inlet Pressure150 psig

-

Normal Operating Pressure Differential40-50 psid

-

Burst Pressure1500 psig

-

Control Range2-100% of Full Scale

-

Typical Accuracy±1% of set point for >20% to 100% Full Scale

± 0.25% of Full Scale for 5% to 20% Full Scale -

Repeatability±0.5% of Reading

-

Resolution0.1% of Reading

-

Zero Temperature Coefficient<0.05% of Full Scale/°C

-

Span Temperature Coefficient<0.08% of Reading/°C

-

Inlet Pressure Coefficient<0.08% of Reading/psi

-

Typical Settling Time<3 sec typical above 10% Full Scale @ 50 psi

-

Warm-up Time1 hour

-

Operating Temperature10-50°C

-

Storage Humidity0-95% Relative Humidity, non-condensing

-

Storage Temperature-20° to 65°C

-

External Leak Integrity<1 x 10-9 (scc/sec He)

-

Leak Integrity Through Closed Valve<1.0% Full Scale at 40 psia to vac (<500 mTorr)

-

Seal MaterialViton®

Buna

Neoprene®

EPDM -

Wetted Materials316 S.S., Elgiloy, 430FR, PTFE (Standard)

-

Surface Finish16 µinch average Ra

-

Enclosure RatingIP66

-

Power Requirements15-24 VDC @ (<8 watts)

-

Flow Input Output SignalVoltage: 0-5 VDC

Current: 4-20 mA -

Analog I/O ConnectorVoltage:15-pin Type "D" male

Current: 15-pin Type "D" male -

Weight12.7 lbs. (5.8 kg)

-

ComplianceCE

Features

Communications

| Digital I/O | Profibus® | PROFINET® |

|---|---|---|

| Input Power Required | +15 to +24 VDC (<2 watts) | +24 VDC (<3 watts) |

| Connector | 9 pin Type D male (power) 9 pin Type D female (comm.) |

2 x RJ-45 (comm.) male M8 male 5 pin (power) |

| Data Rate Switch/Selection | No switch Set data rate via Profibus |

No switch |

| Comm. Rate(s) | 9.6 Kbps to 12 Mbps | 100 Mbps |

| MAC ID Switches/Addresses | 2 switches, 10 positions | n/a |

| Network Size | Up to 99 nodes | n/a |

| Visual Indicators | LED Comm (green/red) LED Error (green/red) |

LED Maint (amber) LED BUS Fault (red) LED Ready (green) LED Sys Fault (red) |

| Compliance | CE | CE |

Fast Settling Time

Settling times of 2 to 3 seconds and set point accuracies below 1% of set point exceed those of other typical high flow MFCs. Precise control is maintained down to 2% of the MFC’s configured Full Scale flow range. The multi-gas/multi-range capability, along with tight performance specifications for accuracy, control range, and transient response allow users to minimize inventory of high flow MFC part numbers.

Multi-Gas / Multi-Range Capability

The multi-gas/multi-range feature (along with other custom controls) is accessed through the MFCs embedded diagnostic interface, which requires no special software or hardware to operate. A standard Ethernet cable and JAVA-enabled HTML browser, widely available, are all the tools needed. The critical gas parameters for typical high flow rate gases are already stored on the device. Configuring the device is simply a matter of selecting the gas from a drop down menu and specifying the desired Full Scale flow range. The diagnostic interface also allows the user to perform routine device health checks, plot flow response, and store operating data for offline analysis.

IP66 Rated Enclosure

Thesre mass flow controllers are designed for use in harsh environments where resistance to liquid and dust ingress are essential. Applications include those where “hose down” may be required, such as industrial glass production where moisture and particulates are present. With its IP66 rated enclosure, these MFCs meet the stringent requirements of these aggressive environments.

Accessories

Resources

Literature

Application Notes

Manuals

- G and I Series Mass Flow Controller/Meter Manual (2.2 MB, PDF)

- G and I-Series Mass Flow Controller/Meter Profibus Manual Supplement (86.9 kB, PDF)

- G-Series/I-Series MFC Modbus Register Map and Specification (502.9 kB, PDF)

- G-Series MFC Web Browser Tutorial (5.6 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity