DA02B 0.1-1000 Torr Heated & Unheated Baratron® Capacitance Manometers with EtherCAT®

Overview

Not recommended for new designs. For new applications see DA05A for Full Scale pressures <1 Torr/mbar and DA07A for Full Scale pressures 1 Torr/mbar and greater.

The DA02B EtherCAT® Baratron® capacitance manometer continues that progression of high performance into networked systems, using industry-standard EtherCAT digital communications to connect to complex process tools. Based on the proven 627C and 628C Ethernet-equipped Baratron products, the EtherCAT Baratron manometer meets the current SEMI® EtherCAT Common Device Profile and is designed for use in advanced processing systems.

- Unheated or controlled to 45°C, 80°C or 100°C

- EtherCAT® Communications and 0-10 VDC output proportional to pressure

- Full Scale measurement ranges from 0.1 to 1000 Torr (13.3 Pa to 133.3 kPa)

- Standard or etch sensors available

- Fully-welded Inconel and Incoloy® sensor for extremely high corrosion resistance

Products

Configuration Options

The following options are available for DA02B Baratron® Heated Capacitance Manometers

Ordering Code Example: DA02B11TCES24C00AA

| Configuration Option | Option Code |

|---|---|

| DA02B Heated Capacitance Manometers | DA02B |

Full Scale Range |

|

| 0.1 | .1 |

| 0.25 | RE |

| 1 | 01 |

| 2 | 02 |

| 10 | 11 |

| 20 | 21 |

| 100 | 12 |

| 200 | 22 |

| 500 | 52 |

| 1000 | 13 |

Units of Measurement |

|

| Torr | T |

| mbar | M |

| kPa | K |

Fittings |

|

| 0.5 in. OD tube | BA |

| 8 VCR female | CE |

| 8 VCR male | CF |

| 8 VCR female, short tube | CR |

| NW16 ISO-KF | GA |

| NW25 ISO-KF | GC |

| 1.33 in. OD CF | HA |

Sensor Type |

|

| Standard sensor, standard inlet tube length | S |

| Standard sensor, reduced inlet tube length (use with fitting code CR) | T |

| Deposition/etch/fluorine friendly sensor (range to 20 Torr) | L |

| Short tube deposition/etch/fluorine friendly sensor (range to 2 Torr, use with fitting code CR) | M |

Analog Output |

|

| 0-10 VDC | 2 |

Sensor Temperature |

|

| unheated | 0 |

| 100°C | 1 |

| 80°C | 8 |

| 45°C | 4 |

Electrical Connector |

|

| (2) RJ45 EtherCAT jacks with 15-pin D-subminiature connector | C |

Calibration Orientation (select V or H for range =1 Torr) |

|

| Standard (ranges > 1 Torr) | 0 |

| Vertical (standard for ranges ≤ 1 Torr) | V |

| Horizontal (available for ranges ≤ 1 Torr only) | H |

Accuracy |

|

| Standard accuracy | 0 |

Trip Points |

|

| None | None |

| Trip A above 50%, Trip B above 50% of Full Scale Range | AA |

| Trip A above 50%, Trip B below 50% of Full Scale Range | AB |

| Trip A below 50%, Trip B below 50% of Full Scale Range | BB |

| Trip A below 50%, Trip B above 50% of Full Scale Range | BA |

| Custom Part numbers can be requested for copy exact applications. Standard part numbers will ship with the latest firmware at the date of manufacture. A custom part number should be requested for locked firmware/EtherCAT ESI file. |

|

Specifications

-

TypeVacuum/pressure Transducer

-

Measurement TypeAbsolute

-

Sensor TemperatureControlled to 45°C, 80°C or 100°C

-

Full Scale Pressure Ranges0.1, 0.25, 1, 2, 10, 20, 50, 100, 200, 500, and 1000 Torr (and metric equivalents)

-

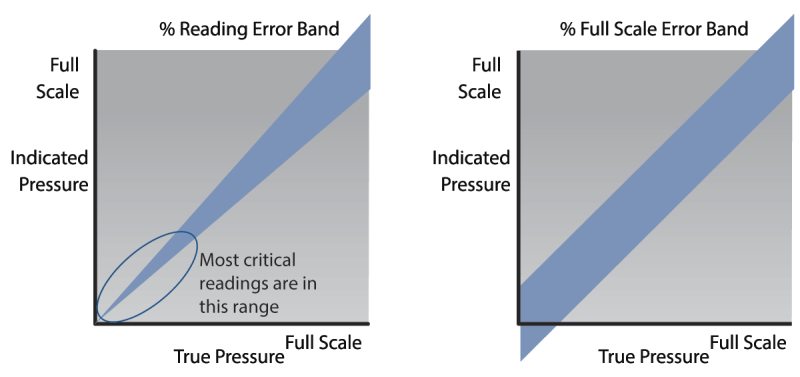

Accuracy45°C Models: 0.10% of Reading for ranges ≥1 Torr, 0.15% Reading for ranges <1 Torr

80° and 100°C Models: 0.25% of Reading for ranges ≥1 Torr, 0.50% of Reading for ranges <1 Torr -

Resolution0.001% Full Scale

-

Communication ProtocolEtherCAT®

-

Analog Output0-10 VDC into >10Ω load

-

Analog Connector15-pin D-subminiature male

-

Digital ConnectorTwo (2) RJ45 female receptacles for incoming and network signals

-

Zero Temperature Coefficient45°C Models:0.002% Full Scale/°C for ranges ≥1 Torr; 0.005% Full Scale/°C for ranges <1 Torr

80° and 100°C Models: 0.002% Full Scale/°C for ranges ≥1 Torr; 0.010% Full Scale/°C for ranges <1 Torr -

Span Temperature Coefficient0.02% Reading/°C

-

Ambient Operating Temperature45°C Models: 15-40°C

80° and 100°C Models: 15-50°C -

Volume6.3 cc

-

Warm-up Time2 hours for ranges ≥1 Torr

4 hours for ranges <1 Torr -

Overpressure Limit45 psia (310 kPa)

-

Exposed MaterialsInconel® and Incoloy® nickel alloys

-

Power Requirements+24 VDC ±10% (Unheated 300mA, 45°C Models 600 mA, 80° and 100°C Models 800 mA)

±15VDC ±5% (Unheated 300mA, 45°C Models 600 mA, 80° and 100°C Models 800 mA) -

Compliance2014/30/EU, 2011/65/EU

Features

Baratron® Capacitance Manometer Technology

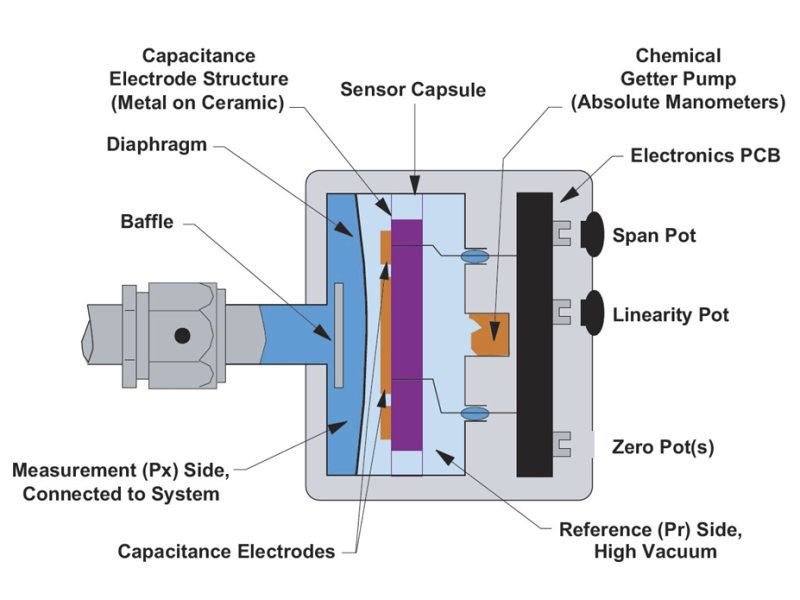

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

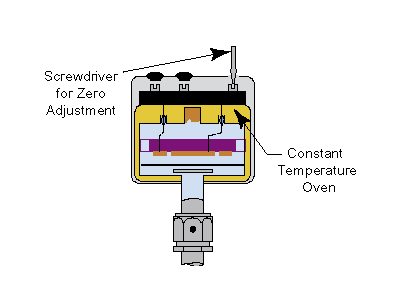

Internally Heated to 45°C, 80°C or 100°C

These capacitance manometers are temperature controlled to 45°C, 80°C or 100°C for improved accuracy. Unheated versions are exposed to ambient temperature variations which can degrade the sensor accuracy. These devices have the sensor enclosed in a volume that is maintained at a constant temperature above ambient. This solution improves the manometer’s accuracy and repeatability and lowers instrument drift by reducing or eliminating process contamination within the manometer. Heated manometers are recommended for applications that require maximum accuracy and repeatability, operate above ambient temperature and for those processes that employ hot gases.

Absolute Pressure Measurement

These Baratron® pressure transducers are referenced to vacuum for absolute pressure measurement. Applications include: vacuum furnaces, freeze-drying of fruits and vegetables, gas lasers, automotive component testing, bottle coatings, and vacuum distillation.

Inconel® and Incoloy® Construction Wetted Surfaces

These pressure transducers feature Inconel® and Incoloy® nickel alloy construction of the pressure sensor allowing it to operate without damage in virtually any chemical environment, including halogens, deionized water and steam, and ozone. The sensor is fully welded with no intermediate brazing or joining materials.

0 to 10 VDC Proportional Analog Output

These Baratron® capacitance manometers feature a high-level 0-10 VDC analog output signal that is linear with pressure. This analog output can be interfaced with an MKS pressure controller, an MKS power supply/display instrument, or any instrument that meets these requirements.

EtherCAT® Communications

These e-Baratron EtherCAT® enabled capacitance manometers continue the progression of high performance into networked systems, using industry-standard EtherCAT digital communications to connect to complex process tools. Based on the proven 627C and 628C Ethernet-equipped e-Baratron products, the EtherCAT e-Baratron manometer meets the current SEMI® EtherCAT Common Device Profile and is designed for use in advanced processing systems.

Accessories

Resources

Literature

Application Notes

- Minimizing Fluorine-Induced Drift in Capacitance Manometers (307.1 kB, PDF)

Manuals

- DA02 Baratron® Capacitance Manometer with EtherCAT® Pin-outs (23.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity