MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

Metal Etch Process Traps

Overview

- Increases throughput and uptime in metal etch processes

- Decreases maintenance frequency and reduces maintenance time

- Eliminates the use of heaters after the trap

- Protects vacuum pump and valves

- High flow conductance

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

MetalEtchTrap Metal Etch Process Trap, Disposable Trapping Element, Effluent Management |

|

Specifications

-

Capacity3 lbs. AICl3Exposed MaterialsStainless Steel, Viton®Flow Conductancep = pressure in mTorr

c = 1355 + 5.73p-

Pressure DropQ = gas flow rate in sccm

= pressure in mTorr

Dp = Q/c -

Dry Weight13 lbs (5.9 kg)

Features

Metal Etch Trap Applications

Aluminum etch systems use chlorine and boron trichloride gases to etch aluminum on wafer surfaces. The byproducts of the aluminum etch process include aluminum chloride that condenses in the downstream pump line and clogs vacuum exhaust lines. This reduces pumping speed and causes process variability and yield loss. The downtime required for periodic cleaning reduces throughput. In addition, solid boric oxide and boric acid are formed by the reaction of BCl3 with water vapor and oxygen in the exhaust line of the dry pump, clogging the entrance to the scrubber.

When a dry chemisorption scrubber is used, solid aluminum chloride often clogs its entrance, and contaminates its chemical adsorbent. Installation of a metal etch trap can extend the scrubber service life significantly.

The Metal Etch Trap, when installed as a component in an Effluent Management Subsystem™, efficiently traps condensable effluents that are generated by aluminum etch processes without reducing pumping speed. High trapping capacity means a longer time between maintenance. Maintenance is simplified by replacing a single disposable trapping element rather than cleaning many feet of vacuum line. Low cost of ownership is achieved by not running heated lines all the way to the scrubber.

Recommended Installation

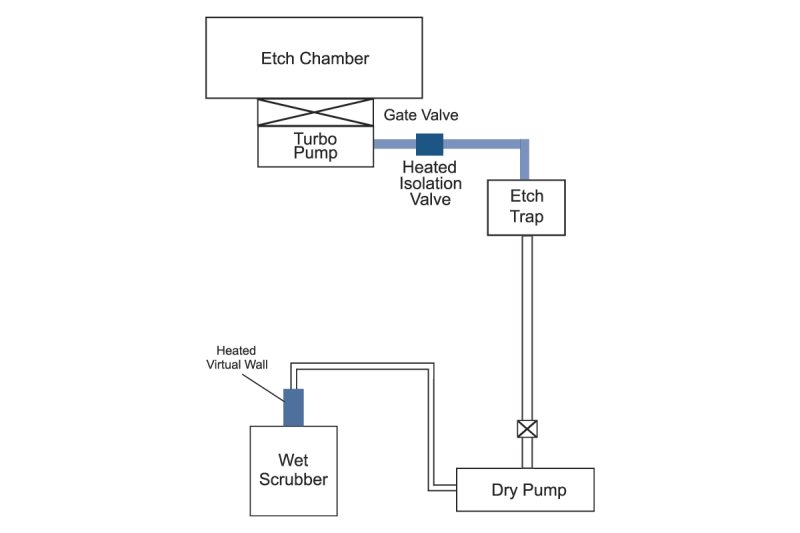

An efficient metal etch Effluent Management Subsystem consists of the Metal Etch Trap, Series 49 heaters, a heated valve, and a Virtual Wall™.

The Metal Etch Trap operates most efficiently when it is installed in the foreline between the turbo pump and the dry pump with a line pressure above 100 mTorr. The Metal Etch Trap operates in conjunction with a heated foreline operating at 105°C which prevents condensation of the exhaust byproducts. The heating of this line must be very uniform, with no cold spots.

The Metal Etch Trap is installed immediately downstream of the heated line no more than 5 to 6 feet from the process chamber. The ability to trap AlCl3 close to the process chamber rather than having to run heated lines 20-30 feet saves a significant amount of money on installation and ongoing maintenance.

Installing a Virtual Wall at the entrance to the scrubber prevents the reaction between BCl3 and water vapor that forms solid byproducts. The Virtual Wall provides a heated nitrogen barrier preventing water vapor from rising out of the wet scrubber into the exhaust line. This prevents the surface reactions that form the solid deposits that clog the entrance to the scrubber.

Ultra-High Velocity

Ultra-High Velocity