MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

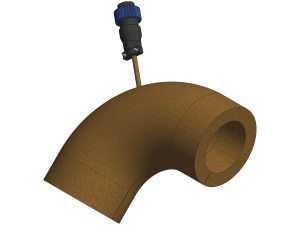

Butt Weld 90 Degree Elbow with Tangents Fittings

Overview

- 90° butt weld elbows with tangents

- 304 Stainless Steel construction

- 0.75 to 6 in. vacuum tubing diameters

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

1002390WT075 90 Degree Elbow Fitting, Buttweld, 0.75 in. O.D. with Tangents, 304 SS |

1 Week

|

$22.46 |

|

|||

|

1002390WT100 90 Degree Elbow Fitting, Buttweld, 1 in. O.D. with Tangents, 304 SS |

1 Week

|

$22.46 |

|

|||

|

1002390WT150 90 Degree Elbow Fitting, Buttweld, 1.5 in. O.D. with Tangents, 304 SS |

In Stock

|

$24.08 |

|

|||

|

1002390WT200 90 Degree Elbow Fitting, Buttweld, 2 in. O.D. with Tangents, 304 SS |

1 Week

|

$44 |

|

|||

|

1002390WT250 90 Degree Elbow Fitting, Buttweld, 2.5 in. O.D. with Tangents, 304 SS |

1 Week

|

$65 |

|

|||

|

1002390WT300 90 Degree Elbow Fitting, Buttweld, 3 in. O.D. with Tangents, 304 SS |

1 Week

|

$73 |

|

|||

|

90 Degree Elbow Fitting, Buttweld, 4 in. OD with Tangents, 0.083 in. 304 SS

$115

1 Week

|

1002390WT400 90 Degree Elbow Fitting, Buttweld, 4 in. OD with Tangents, 0.083 in. 304 SS |

1 Week

|

$115 |

|

||

|

90 Degree Elbow Fitting, Buttweld, 4 in. OD with Tangents, 0.065 in. 304 SS

$115

1 Week

|

1002390WT401 90 Degree Elbow Fitting, Buttweld, 4 in. OD with Tangents, 0.065 in. 304 SS |

1 Week

|

$115 |

|

||

|

1002390WT600 90 Degree Elbow Fitting, Buttweld, 6 in. O.D. with Tangents, 304 SS |

1 Week

|

$357 |

|

Specifications

-

Component Type90 Degree Elbow with Tangents

-

Fitting TypeButt Weld

-

SeriesSeries 23

-

Material304 Stainless Steel

Features

Buttweld Component Construction

The Series 23 components are constructed of 304 or 304L welded, drawn, and annealed stainless steel tubing. (316L is available on request.) For most vacuum process applications, this provides the best combination of the following critical features:

- Low outgassing under vacuum

- Chemically resistant

- Annealed for consistent leak free welding

- Minimized corrosion concentration points

- Good availability

- Cost consistent with the above requirements

Each component is fabricated using pulled port and 100% penetration TIG weld techniques. All welded components are leak free, carefully cleaned for high vacuum use and then packaged to remain clean until the time of installation.

Recommended Welding Techniques

Series 23 fittings are designed to be welded using techniques preferred for vacuum applications. These techniques include internal (socket type) welding and external buttwelding. The most commonly used type of weld for high vacuum applications is a TIG (Tungsten Inert Gas) fusion weld, preferably without filler rod. For the best results, remove components from packaging in clean conditions during installation. Handle the components with clean gloves and equipment in the absence of any fibers, fingerprint oils, or other greases. If these precautions are taken, the weld is more likely to be leak free and the integrity of the vacuum surface will remain intact and ready for use.

General hints for good vacuum welds include:

- Always start with clean and properly weld prepped components.

- For internal welds, minimize warping by using only enough heat for 60-75% penetration.

- For external buttwelds, make sure they are 100% penetration with no internal cracks or crevices.

- Do not weld internally then externally around the entire circumference of the fittings.

- Make sure there is little or no gap between pieces to be welded.

- Ensure that all surfaces affected by the heat of the weld, especially the vacuum side, are purged properly with inert gas.

Applications

Vacuum buttweld fittings are designed to be used in any vacuum applications where minimizing the number of sealed joints is critical.

- Semiconductor wafer fabrication areas for remote installations and below a raised floor

- Permanent house vacuum lines

- Vacuum utility lines for vacuum fixtures

- High temperature lines

- Burn box exhaust lines

Resources

Literature

- Series 23 ButtWeld Vacuum Components & Fittings (2 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity