Ion Implantation Solutions

The primary method of doping silicon for semiconductor device manufacturing has been ion implantation, gas source doping, and solid source doping. Ion implantation is by far the most important mode of introducing dopant atoms into silicon substrates, addressing the increasing complexity of semiconductor chips and the processes that fabricate them.

The success of ion implantation processes is heavily dependent on the quality of the vacuum within ion implanters. Most of MKS' solutions for high vacuum applications in vacuum generation, control and monitoring are critical to the success of the ion implant process.

Learn More:

MKS Handbook Second Edition

Semiconductor Devices and Process Technology

Detailing the fundamental device physics, materials, and fabrication processes used to manufacture semiconductors.

A free book from MKS

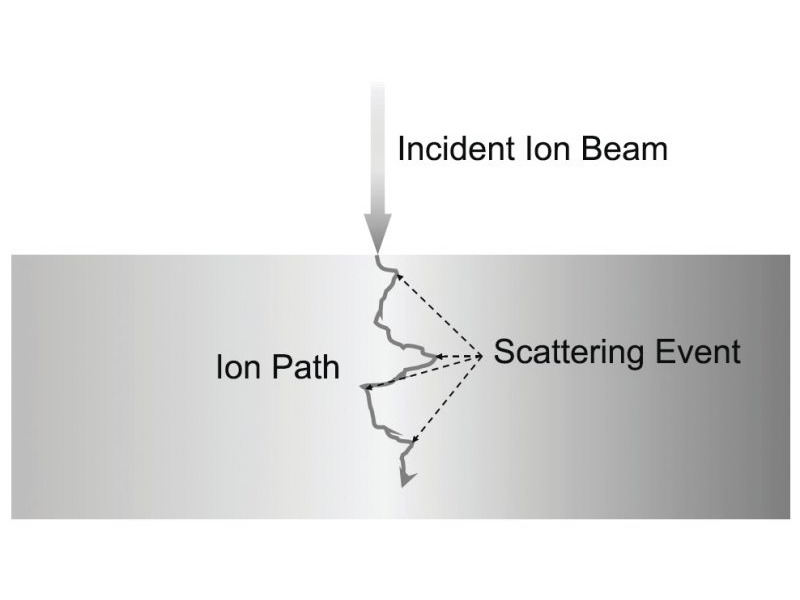

Ion Implantation

A detailed explanation of the most important mode of introducing dopant atoms into silicon substrates

Remote Plasma Sources for Clean Applications

For cleaning CVD and ALD/ALE process chambers

Residual Gas Analyzers

An effective tool to analyze system gas loads resulting from real leaks, virtual leaks or chamber wall outgassing.

Vacuum Flanges & Fittings

ISO-KF, ISO-MF, ISO-BF, CF (ConFlat), and welded style vacuum fittings, vacuum flanges and vacuum components

Baratron® Capacitance Manometers

For direct, gas independent, high accuracy pressure measurement

Ultra-High Velocity

Ultra-High Velocity