MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

E28H 0.05-100 Torr Heated (100°C) Baratron® Capacitance Manometers with Etch Sensor

Overview

The E28H temperature regulated capacitance manometer features structures in the sensor housing that eliminate process byproducts from depositing on the surface of the diaphragm, minimizing drift. The E28H Baratron® manometer is temperature controlled to 100°C, accurate to 0.25% of Reading and includes updated temperature control electronics to provide superior long-term stability and repeatability.

- Temperature controlled to 100°C for up to 0.25% of reading accuracy

- 0 to 10 VDC analog output proportional to absolute pressure

- Etch baffle sensor significantly reduces the ability of byproducts to reach the sensor

- Full Scale ranges low as 50 mTorr for precise low pressure measurement

- All Inconel® sensor-corrosion resistant wetted surfaces

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

Heated Capacitance Manometer w/Etch Sensor, 0.1 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration

$3,374

|

E28H.1TBF5B Heated Capacitance Manometer w/Etch Sensor, 0.1 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration | $3,374 |

|

|||

|

Heated Capacitance Manometer w/Etch Sensor, 0.1 Torr, 100°C, NW16 ISO-KF, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration

$3,374

|

E28H.1TDF5B Heated Capacitance Manometer w/Etch Sensor, 0.1 Torr, 100°C, NW16 ISO-KF, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration | $3,374 |

|

|||

|

Heated Capacitance Manometer w/Etch Sensor, 10 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.25%/Rdg Accuracy, Vertical Calibration

$3,374

|

E28H11TBE1B Heated Capacitance Manometer w/Etch Sensor, 10 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.25%/Rdg Accuracy, Vertical Calibration | $3,374 |

|

|||

|

Heated Capacitance Manometer w/Etch Sensor, 10 Torr, 100°C, NW16 ISO-KF, DB15 w/Thread Lock, 0.25%/Rdg Accuracy, Vertical Calibration, Status LED

$3,527

|

E28H11TDE2B Heated Capacitance Manometer w/Etch Sensor, 10 Torr, 100°C, NW16 ISO-KF, DB15 w/Thread Lock, 0.25%/Rdg Accuracy, Vertical Calibration, Status LED | $3,527 |

|

|||

|

Heated Capacitance Manometer w/Etch Sensor, 0.05 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration, Status LED

$3,679

|

E28HU5TBF6B Heated Capacitance Manometer w/Etch Sensor, 0.05 Torr, 100°C, 8 VCR-F, DB15 w/Thread Lock, 0.50%/Rdg Accuracy, Horizontal Calibration, Status LED | $3,679 |

|

Configuration Options

The following options are available for E28H Baratron® Heated Absolute Capacitance Manometers

Ordering Code Example: E28H01TBE1B

| Configuration Option | Option Code |

|---|---|

| E28H Absolute Capacitance Manometer. | E28H |

Full Scale Range |

|

| 0.05 Torr | U5T |

| 0.1 Torr | .1T |

| 0.25 Torr | RET |

| 1 Torr | 01T |

| 2 Torr | 02T |

| 10 Torr | 11T |

| 20 Torr | 21T |

| 100 Torr | 12T |

Fittings |

|

| 0.5 in. OD Tube | A |

| 8 VCR female | B |

| 1.33 in. OD CF | C |

| NW16 ISO-KF | D |

| 8 VCO female | E |

| 2.75 in. OD CF | L |

| NW25 ISO-KF | Q |

Accuracy |

|

| 0.25% of Reading | E |

| 0.50% of Reading | F |

Options |

|

| Standard Configuration, vertical calibration | 1 |

| Temperature/Heater Status, vertical calibration | 2 |

| Standard Configuration, horizontal calibration (ranges <1 Torr only) | 5 |

| Temperature/Heater Status, horizontal calibration (ranges <1 Torr only) | 6 |

Connector |

|

| 15 pin Type "D" with Thread Locks | B |

| 15 pin Type "D" with Slide Locks | P |

Specifications

-

TypeVacuum/pressure Transducer

-

Measurement TypeAbsolute

-

Sensor TemperatureControlled to 100°C

-

Full Scale Pressure Ranges0.05, 0.1, 0.25, 1, 2, 10, 20, and 100 Torr

-

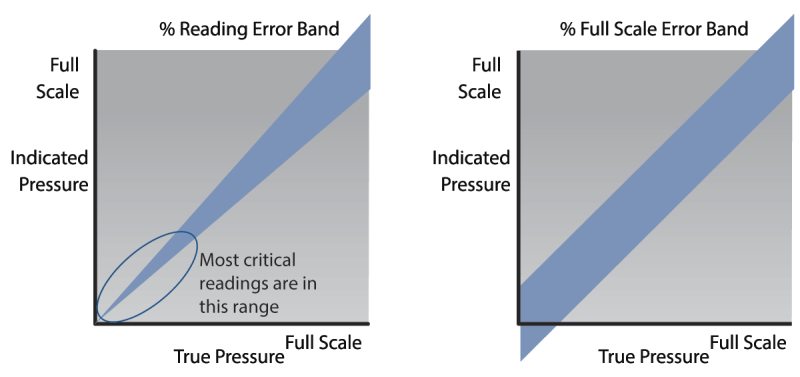

Accuracy0.25% of Reading

0.5% for <1 Torr and 0.05 Torr -

Analog Output0-10 VDC into >10K Ω load

-

Zero Temperature Coefficient0.002% of Full Scale/°C for 1-100 Torr ranges

0.01% Full Scale/°C for 0.1 Torr

0.02% Full Scale/°C for 0.05 Torr -

Span Temperature Coefficient0.02% of Reading/°C

-

Operating Temperature Range15-50°C

-

Volume6.3 cc

-

Warm-up Time2 hours for 1 Torr and higher

4 hours for <1 Torr -

Overpressure Limit45 psia (310 kPa) or 120% Full Scale, whichever is greater

-

Exposed MaterialsInconel®

-

Power Requirements±15 VDC ±5% @ 0.6 Amps (maximum)

-

ComplianceCE

Features

Baratron® Capacitance Manometer Technology

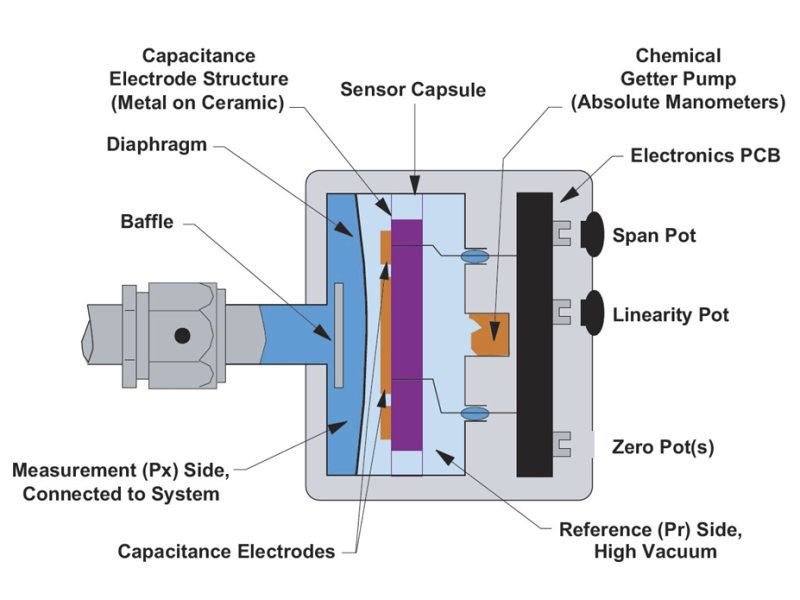

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Internally Heated to 100°C

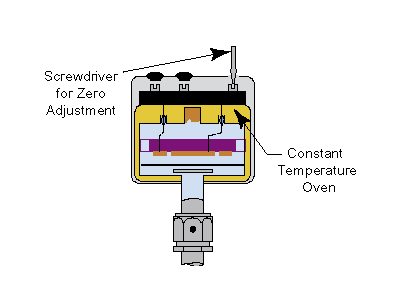

These capacitance manometers are temperature controlled to 100°C for improved accuracy. Unheated versions are exposed to ambient temperature variations which can degrade the sensor accuracy. These devices have the sensor enclosed in a volume that is maintained at a constant temperature above ambient. This solution improves the manometer’s accuracy and repeatability and lowers instrument drift by reducing or eliminating process contamination within the manometer. Heated manometers are recommended for applications that require maximum accuracy and repeatability, operate above ambient temperature and for those processes that employ hot gases.

Absolute Pressure Measurement

These Baratron® pressure transducers are referenced to vacuum for absolute pressure measurement. Applications include: vacuum furnaces, freeze-drying of fruits and vegetables, gas lasers, automotive component testing, bottle coatings, and vacuum distillation.

All-Inconel® Wetted Surfaces

These pressure transducers feature all Inconel® construction of the pressure sensor allowing it to operate without damage in virtually any chemical environment, including exposure to halogens, deionized water and steam, and ozone.

0 to 10 VDC Proportional Analog Output

These Baratron® capacitance manometers feature a high-level 0-10 VDC analog output signal that is linear with pressure. This analog output can be interfaced with an MKS pressure controller, an MKS power supply/display instrument, or any instrument that meets these requirements.

Recommended for Etch Processes

MKS has implemented solutions within the manometer’s pressure sensing element to minimize the effects of process byproducts and process gases. For processes that generate large quantities of condensable byproducts, MKS recommends the etch baffle sensor that significantly reduces the ability of byproducts to reach the sensor, minimizing process-induced zero drift. For very low pressure processes where fluorine burn-in is the main issue, MKS recommends the fluorine friendly (FF) sensor offering the ultimate in short- and long-term stability in fluorine chemistry.

15-pin D-subminiature Connector

| Pin | Description |

|---|---|

| 2 | Signal Output |

| 5 | Power Common |

| 6 | -15 VDC |

| 7 | +15 VDC |

| 12 | Signal Common |

| 15 | Chassis Ground |

Accessories

Resources

Literature

- E28H Heated (100°C) Baratron® Capacitance Manometer with Etch Sensor (1.5 MB, PDF)

- Analog 600 Series Absolute Baratron® Capacitance Manometer Selection Guide (2.9 MB, PDF)

Application Notes

- Minimizing Fluorine-Induced Drift in Capacitance Manometers (307.1 kB, PDF)

Manuals

- MKS E28H Manometer Manual (602 kB, PDF)

- 626, 627, 628, E27 & E28 Capacitance Manometer Pin-outs (22.4 kB, PDF)

Drawings & CADs

- E28 Dimensional Drawing (126.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity