MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

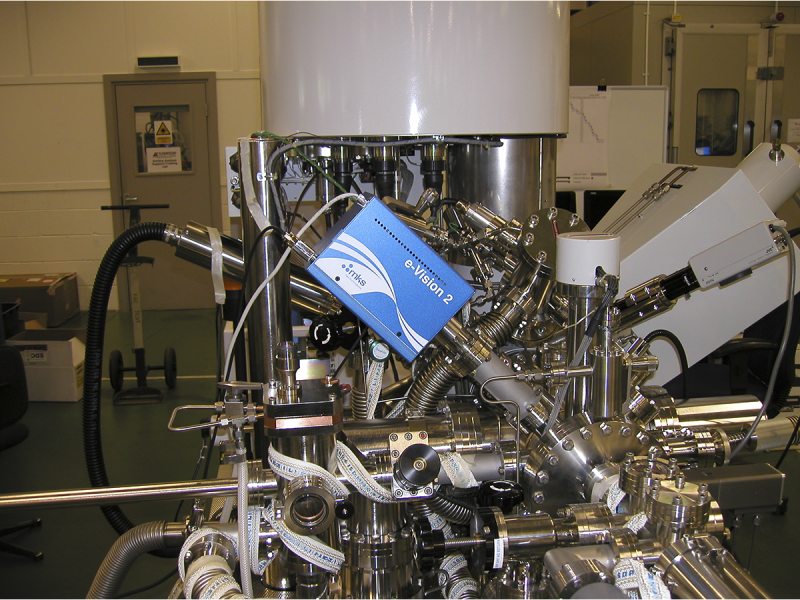

e-Vision 2 General Purpose Residual Gas Analyzer

Overview

The e-Vision 2 RGA is one of a new range of residual gas analysis products, from MKS, designed to meet all the traditional requirements for an RGA sensor but with data collection at speeds unachievable with previous generation technologies. The e-Vision 2 RGA is designed to provide maximum value for money.

- Leak detection of vacuum lines, welds and seals

- Vacuum diagnostics

- Pump down monitoring

- Chamber bake out monitoring

- Leak checking of coolant lines within a vacuum chamber

- Chamber contaminant monitoring

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

EV2-110-000 Residual Gas Analyzer, 1-100 amu, Faraday Detector, Open Ion Source |

In Stock

|

$5,733 |

|

|||

|

Residual Gas Analyzer, 1-100 amu, Multichannel Plate Dual Detector, Open Ion Source

$7,294

In Stock

|

EV2-120-000 Residual Gas Analyzer, 1-100 amu, Multichannel Plate Dual Detector, Open Ion Source |

In Stock

|

$7,294 |

|

||

|

EV2-210-000 Residual Gas Analyzer, 1-200 amu, Faraday Detector, Open Ion Source | $6,860 |

|

||||

|

Residual Gas Analyzer, 1-200 amu, Multichannel Plate Dual Detector, Open Ion Source, Tungsten Filaments

$8,713

In Stock

|

EV2-220-000 Residual Gas Analyzer, 1-200 amu, Multichannel Plate Dual Detector, Open Ion Source, Tungsten Filaments |

In Stock

|

$8,713 |

|

Configuration Options

e-Vision 2 General Purpose Residual Gas Analyzers are also available with the following options.

Ordering Code Example: EV2-120-000

| Configuration Option | Option Code |

|---|---|

|

e-Vision 2 Residual Gas Analyzer |

EV |

Software Option |

|

| Web Application Only | 2 |

| EasyView | E |

Mass Range |

|

| 100 amu | 1 |

| 200 amu | 2 |

Detector Type |

|

| Faraday Only | 1 |

| Multichannel Plate Dual | 2 |

Reserved |

|

| Reserved | 0-00 |

Filament |

|

| Tungsten Filaments | 0 |

| Thoria Coated Iridium | 1 |

Specifications

-

TypeResidual Gas Analyzer

-

Measurement TechniqueMass Spectrometry

-

Mass Range1-100 or 1-200 amu

-

FilamentsTungsten or Thoria Coated Iridium

-

SoftwareBuilt-in web applications allowing RGA control and data acquisition without installed software using web browser on any PC

Optional Easy View Software available -

Filter length4 in. (100 mm)

-

Maximum Analyzer Operating Pressure1e-4 Torr (1.3e-4 mbar)

-

Ion Source Sensitivity5e-5 A/mbar

-

Minimum Detectable Concentration7.5e-11 Torr (1e-10 mbar) Faraday

2e-13 Torr (2.5e-13 mbar) Multiplier -

Mass Stability±0.1 amu over 8 hours at stable ambient

-

Bake Out Temperature250°C with electronics removed

-

Operating Temperature200°C Faraday only with electronics 10-40°C

150°C Multiplier with electronics 10-40°C and pressure <1e-8 mbar

90°C Multiplier with electronics 10-40°C and pressure <1e-5 mbar -

Data Acquisition MethodDedicated realtime acquisition processor

-

Data Acquisition Speed<3ms per point for analog scans

-

Data Collection MethodsAnalog scanning, full mass range 8, 16 or 32 points/amu

Barchart scanning

Peak-jump collection of up to 15 peaks per scan -

Settling Time<20ms

-

Control MethodCE operating system processor with web-server interface

-

Command StructureDocumented ASCII command protocols

-

Electron Energy & Emission Current40 or 70eV fixed (set in web configuration)

-

Filament ProtectionOpto-isolated input for filament protect or control with auto detection of presence of the jack plug as failsafe

-

Communication10/100 Base-T Ethernet, static or automatically assigned IP addresses

-

ComplianceCE (control unit)

Features

Sensor Performance

Field proven MKS quadrupole mass analyzers, with twin filaments as standard, ensure minimum downtime during critical diagnostic testing. The RGA is available with an optional dual detector including a faraday detector and microchannel plate electron multiplier for detection to e-14 mbar.

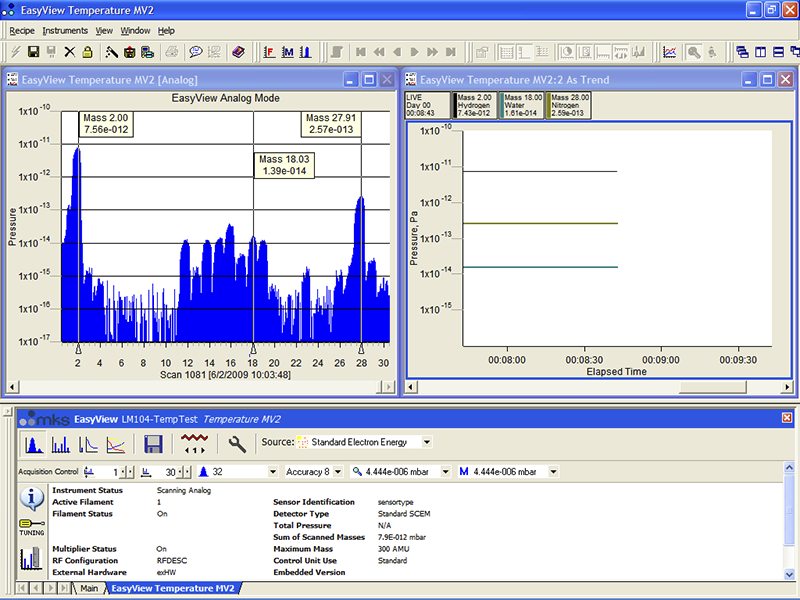

Electronics Performance

Data acquisition occurs through all solid state, wide dynamic range, fast settling detector electronics. This technology prevents large peaks from causing false positive measurements on small peaks. Temperature stabilized critical components mean that signal stability and baseline drift are improved, allowing the unit to be used without frequent recalibration if the vacuum chamber is stable but ambient air temperature fluctuates.

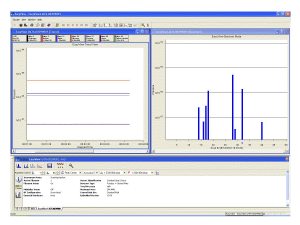

Built-in Web Application

A web interface using industry standard technology allows control of the e-Vision 2 as well as calibration, operation and data export through a non platform-specific web browser from anywhere on a network. Using the ASCII protocol and TCP-IP communication, any third party software can send and receive commands and data from the e-Vision 2.

EasyView Software

In addition to the standard, built-in web applications, software control is also available through an optional Windows application, offering the best possible fit to any customer requirement. The field proven software provides basic RGA controls but with more functionality than the built-in web application.

- Store RGA data and recall it back into the Recall viewer

- Annotate graphs with notes

- Run several RGAs from one software package

Applications

The e-Vision 2 is suitable for a wide range of applications including:

- Leak detection of vacuum lines, welds and seals

- Vacuum diagnostics

- Pump down monitoring

- Chamber bakeout monitoring

- Leak checking of coolant lines within a vacuum chamber

- Chamber contaminant monitoring

- Monitor cryo-pump performance

- Monitor getter performance

Accessories

Resources

Literature

- e-Vision 2 General Purpose Residual Gas Analyzer (RGA) (2.2 MB, PDF)

Drawings & CADs

- e-Vision 2 Dimmensional Drawing (476.4 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity