MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

AA08B Micro-Baratron® High Pressure, Ultraclean, Flow-through, Pressure Transducers

Overview

The AA08B Micro-Baratron® is a higher accuracy, flow-through pressure transducer offering superior value and performance. The building block design of Micro-Baratron® pressure transducers allow custom configuration. A highly accurate and stable sensor with sophisticated electronics optimize performance with EMI/RFI insensitive, high level output. The AA08B offers enhanced accuracy, long term stability and low temperature coefficients for repeatability important in today's gas measurement applications.

- Flow-through configuration for in-line pressure measurement

- Incoloy® wetted surface for superior corrosive gas & liquid compatibility

- Highest overpressure ratio tolerances on the market

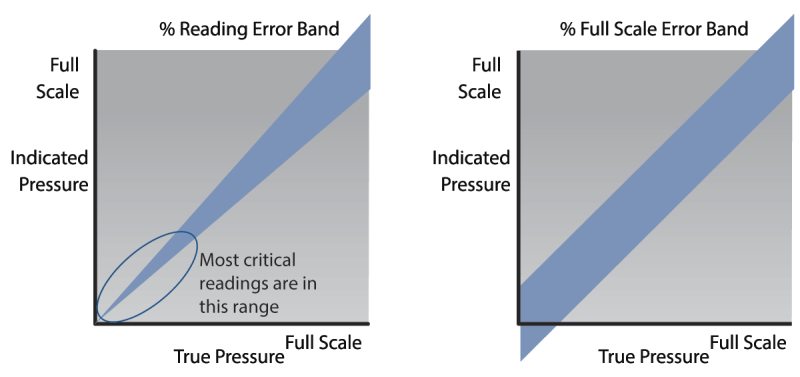

- Accuracy specified in percentage of reading for superior results in lower pressure ranges

- Capacitance technology at a competitive price

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

Pressure Transducer, 100 psia, Flow-through, 0-10 VDC, 4 VCR Female, 15-pin HD

$1,290

15 Weeks

|

AA08B12PCJ2GC1 Pressure Transducer, 100 psia, Flow-through, 0-10 VDC, 4 VCR Female, 15-pin HD |

15 Weeks

|

$1,290 |

|

||

|

Pressure Transducer, 100 psia, Flow-through, 0-10 VDC, 4 VCR Female, 15-pin HD, LDM-C

$1,747

|

AA08B12PCJ2GT1 Pressure Transducer, 100 psia, Flow-through, 0-10 VDC, 4 VCR Female, 15-pin HD, LDM-C | $1,747 |

|

|||

|

Pressure Transducer, 1000 psia, Flow-through, 0-5 VDC, 4 VCR Male, DB15, LDM-C

$1,716

15 Weeks

|

AA08B13PCH3GW1 Pressure Transducer, 1000 psia, Flow-through, 0-5 VDC, 4 VCR Male, DB15, LDM-C |

15 Weeks

|

$1,716 |

|

||

|

Pressure Transducer, 1000 psia, Flow-through, 0-10 VDC, 1.125 inch W-seal, Bendix 4-pin

|

AA08B13PMF2GD1 Pressure Transducer, 1000 psia, Flow-through, 0-10 VDC, 1.125 inch W-seal, Bendix 4-pin |

|

||||

|

Pressure Transducer, 1000 Torr, Flow-through, 0-10 VDC, 4 VCR-M, 15-pin HD on Flying Lead

$1,716

|

AA08B13TCA2GT1 Pressure Transducer, 1000 Torr, Flow-through, 0-10 VDC, 4 VCR-M, 15-pin HD on Flying Lead | $1,716 |

|

|||

|

Pressure Transducer, 1000 Torr, Flow-through, 0-5 VDC, 1.125 inch C-seal, 15-pin HD on Flying Lead

|

AA08B13TMD3GC1 Pressure Transducer, 1000 Torr, Flow-through, 0-5 VDC, 1.125 inch C-seal, 15-pin HD on Flying Lead |

|

||||

|

Pressure Transmitter, 3000 psia, Flow-through, 4-20 mA, 0.25 in. Weld Stubs, Flying Leads

$1,504

|

AA08B33PBE4GL4 Pressure Transmitter, 3000 psia, Flow-through, 4-20 mA, 0.25 in. Weld Stubs, Flying Leads | $1,504 |

|

|||

|

Pressure Transducer, 3000 psia, Flow-through, 0-10 VDC, 4 VCR male, DB9 on Flying Lead

$1,262

15 Weeks

|

AA08B33PCH2GA1 Pressure Transducer, 3000 psia, Flow-through, 0-10 VDC, 4 VCR male, DB9 on Flying Lead |

15 Weeks

|

$1,262 |

|

||

|

Pressure Transducer, 250 psia, Flow-through, 0-10 VDC, 4 VCR Male, DB9 on Flying Lead

$1,260

|

AA08BRDPCH2GA1 Pressure Transducer, 250 psia, Flow-through, 0-10 VDC, 4 VCR Male, DB9 on Flying Lead | $1,260 |

|

Configuration Options

The following options are available for the AA08B Micro-Baratron® High Pressure Flow-Though Pressure Transducer.

Ordering Code Example: AA08B33PCB2GA1

| Configuration Option | Option Code |

|---|---|

| AA08B Single-ended Pressure Transducer | AA08B |

Pressure Range Full Scale* |

|

| 1000 Torr | 13T |

| 100 psia | 12P |

| 250 psia | RDP |

| 1000 psia | 13P |

| 3000 psia | 33P |

Fittings |

|

| 0.25 in. weld stub (1.85 in. face-to-face) | BE |

| 4 VCR male, nonrotatable (2.78 in. face-to-face) | CA |

| 4 VCR male, nonrotatable (2.24 in. face-to-face) | CH |

| 4 VCR female (2.95 in. face-to-face) | CJ |

| 4 VCR male, nonrotatable / 0.25 in. weld stub | CL |

| 4 VCR female (3.045 in. face-to-face) | CM |

| 1.5 in. C-seal surface mount | MA |

| 1.5 in. W-seal surface mount | MC |

| 1.125 in. C-seal surface mount | MD |

| 1.125 in. W-seal surface mount | MF |

Analog Output |

|

| 0-10 VDC | 2 |

| 0-5 VDC | 3 |

| 4-20 mA | 4 |

| Accuracy | |

| 1% of Reading | G |

Connectors |

|

| 9-pin type D at end of 9” flying lead | A |

| 15-pin high density type D at end of 9” flying lead | C |

| Bendix 4-pin at end of 9” flying lead | D |

| 6’ flying leads | F |

| 10’ flying leads | L |

| Bendix 4-pin 4-20 mA on pins A&B | H |

| LDM-C (Red LED), 0-5 VDC and 0-10 VDC with high density D connector | T |

| LDM-C (with Blank Cover), 0-5 VDC and 0-10 VDC with high density D connector | W |

Environmental |

|

| Standard enclosure (indoor use) | 1 |

| Optional NEMA 4 enclosure for water, ice and dust | 4 |

* Other engineering units available (i.e. KPa). Consult Applications Engineering for additional information

Specifications

-

TypePressure Transducer

-

ConfigurationFlow-through

-

Measurement TypeAbsolute

-

Full Scale Pressure1000 Torr to 3000 psia

-

Accuracy1.0% of Reading

-

Fitting Type0.25 in. weld stub (1.85 in. face-to-face)

4 VCR male, nonrotatable (2.78 in. face-to-face)

4 VCR male, nonrotatable (2.24 in. face-to-face)

4 VCR female (2.95 in. face-to-face)

4 VCR male, nonrotatable / 0.25 in. weld stub

4 VCR female (3.045 in. face-to-face)

1.5 in. C-seal surface mount

1.5 in. W-seal surface mount

1.125 in. C-seal surface mount

1.125 in. W-seal surface mount -

Zero Temperature Coefficient0.02% of Full Scale/°C, 50 psia to 3000 psia

0.04% of Full Scale/°C, 1000 Torr -

Span Temperature Coefficient0.04% of Reading/°C, 50 psia to 3000 psia

0.08% of Reading/°C, 1000 Torr

-

Overpressure Limit1.5 x Full Scale for ranges from 1000 Torr to 500 psi

1.2 x Full Scale for ranges from 501-3000 psi -

Burst Pressure10 x Full Scale for ranges from 1000 Torr to 500 psi

5 x Full Scale for ranges from 501-3000 psi -

Exposed MaterialsIncoloy®

-

Surface Finish≤10 µin Ra

-

Power Requirements13 to 32 VDC @ 10 mA max.

-

Ambient Operating Temperature0-50°C

-

ComplianceCE

Features

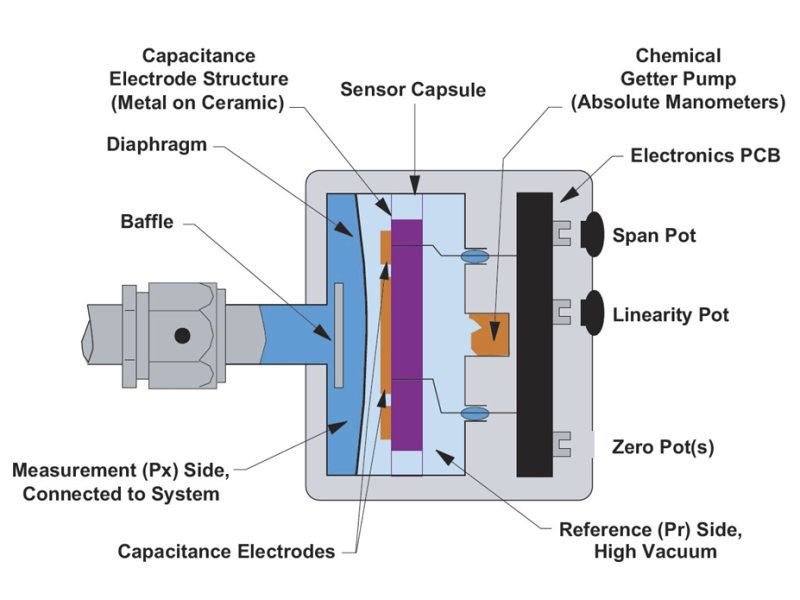

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Ideally Suited for Ultrapure Gas Delivery Systems

The AA07/AA08 transducers are ideally suited for use in delivery systems that feed ultrapure gases to critical process systems. Their wetted surfaces exposed to the gas stream have a finish of better than 5 µin Ra. These transducers exhibit superior dry-down characteristics, and contribute no particles above background. After manufacture and assembly, they are purged with ultraclean nitrogen prior to double bagging in a class 100 environment.

All Incoloy® Construction

The all-Incoloy® construction of the sensors in the AA07/AA08 allow for high overpressure tolerances that reduce errors due to line pressure spikes. High burst pressure ratings contribute to overall system safety. On existing gas cabinets and process systems, field replacement of common dial gauges or lower performance transducers is made easy due to the small size, industry standard endto-end lengths, and electrical interface choices of these transducers.

Optional Local Display

The optional local integrated display provides a digital readout of the line pressure at the transducer. The display, which is available on the 1000 Torr, 100 and 250 PSIA ranges with the 0-10 VDC output signal, provides a highly visible red LED display of the pressure and the units of measurement. The display can also be switched to show any of four different units (PSIA, Torr, bar, and kPa) without requiring recalibration or re-ranging of the transducer itself. It takes its power from the incoming transducer voltage, so no additional cables are required.

Resources

Literature

- AA07B, AA08B Micro-Baratron® Pressure Transducers (2.2 MB, PDF)

Manuals

- MKS AA07B & AA08B Transducers Manual (758.6 kB, PDF)

Drawings & CADs

- AA07 & AA08 Baratron® Pressure Transducer Dimensional Drawing (1,009.5 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity