MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

423 I-Mag® & 431 Cold Cathode Vacuum Pressure Sensors

Overview

Using an inverted magnetron design, 423 I-Mag® vacuum pressure sensors can operate at pressures as low as 10-10 Torr with the proper controller which is much lower than a traditional Penning cold cathode sensor. This increased pressure range makes the Cold Cathode sensors ideal for for OEM or industrial use.

- Wide pressure measurement range 10-10 to 10-2 Torr

- No adjustment in emission current or filament voltage required

- No need to degas the gauge and no filaments to burn out

- Sensor tubes can be mounted in any position without affecting reading

- Cleaning of sensor is easy with a demountable tube

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, NW40 ISO-KF

$549

|

104230001 Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, NW40 ISO-KF | $549 |

|

|||

|

Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, 2.75 in. OD CF

$628

In Stock

|

104230002 Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, 2.75 in. OD CF |

In Stock

|

$628 |

|

||

|

Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, 1 in. OD Tube

$500

|

104230003 Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, 1 in. OD Tube | $500 |

|

|||

|

Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, NW25 ISO-KF

$476

|

104230004 Vacuum Gauge, Cold Cathode Sensor, 1 x 10-11 to 1 x 10-2 Torr, NW25 ISO-KF | $476 |

|

|||

|

104310001 Cold Cathode Vacuum Sensor, 1 x 10-11 - 1 x 10-2 Torr, NW40-KF | $1,248 |

|

||||

|

104310002 Cold Cathode Vacuum Sensor, 1 x 10-11 - 1 x 10-2, 2.75 in. CF | $1,248 |

|

||||

|

104310003 Cold Cathode Vacuum Sensor, 1 x 10-11 - 1 x 10-2 Torr, 1 in. tube | $1,132 |

|

||||

|

104310004 Cold Cathode Vacuum Sensor, 1 x 10-11 - 1 x 10-2 Torr, NW25-KF | $1,187 |

|

||||

|

104310005 Cold Cathode Vacuum Sensor, 1 x 10-11 - 1 x 10-2 Torr, 8 VCR female | $1,193 |

|

Specifications

-

Sensor TypeI-Mag® Cold Cathode

-

Measurement Range1 x 10-11 to 1 x 10-2 Torr

1 x 10-11 to 1 x 10-2 mbar

1 x 10-9 to 1.0 Pa -

ConnectorsTube Side: molded connector with a positive locking bolt

Controller Side: bayonet connector and threaded coaxial connector -

Exposed MaterialsStainless steel, 6061 aluminum, Inconel®, glass and alumina ceramic

-

Reproducibility5% of reading at constant temperature

-

Bake Out Temperatureto 400°C (752°F) with CF flanges and magnet and cable removed

-

Operating Temperature0° to 70°C (32° to 158°F)

-

Calibration GasAir, Nitrogen

-

Installation OrientationAny

-

Internal Volume15 cc

-

Weight2.0 lbs (0.8 kg) with CF flange

Features

Second Feedthrough for Ion Collection

A unique design feature of the Cold Cathode sensors is a second feedthrough for ion collection. In an ordinary single feedthrough design, any current leakage between the anode and ground would result in pressure measurement errors. Only the ion current from the cathode contributes to a measurement reading in a dual feedthrough design, making it ideal for process monitoring.

No Filament to Burn Out

With no filament to burn out, these cold cathode sensors are not ruined by sudden inrushes of air and are resistant to vibration damage. Additionally, there is no need to adjust the emission current or to degas the gauge, reducing response time to pressure changes.

Accessories

Resources

Drawings & CADs

- 423 I-Mag® Cold Cathode Vacuum Sensor Dimensional Drawing (58.1 kB, PDF)

Manuals

- 423 I-MAG Cold Cathode Ionization Vacuum Sensor Manual (166.9 kB, PDF)

Literature

- 937B Digital Combination Vacuum Gauge Controller (585.5 kB, PDF)

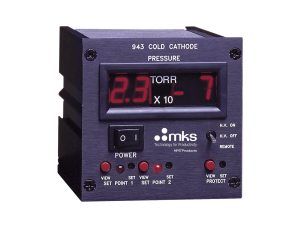

- 943 Cold Cathode Vacuum Gauge System (305.7 kB, PDF)

- Vacuum Measurement Product Guide (711.5 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity