MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

392 Micro-Ion® Plus Modular Vacuum Pressure Transducers

Overview

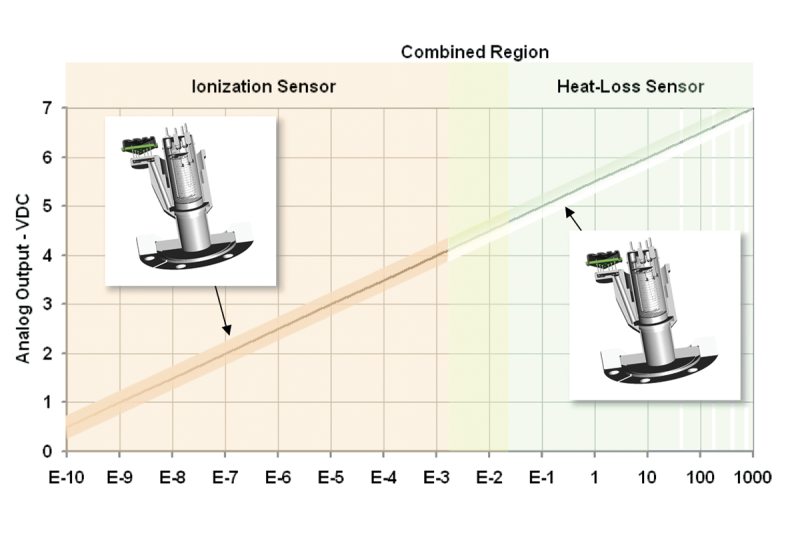

The 392 Micro-Ion® Plus is a second generation full range pressure measurement module that combines industry-standard Micro-Ion® ionization gauge technology with a miniature Pirani Conductron heat-loss sensor to provide accurate, continuous pressure measurement from high vacuum to atmosphere.

- Continuous pressure measurement from 10-9 Torr to atmosphere

- Dual ionization gauge filaments that increase equipment uptime

- EtherCAT, RS-485 and DeviceNet have optional setpoint relays for process control

- Automation of ionization gauge activation and deactivation

- Field replaceable gauge assembly for low Cost-of-Ownership

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

392502-2-YE-T Vacuum Gauge, Micro-Ion Plus, Display, NW25 ISO-KF, RS485, 2 Relays |

14 Weeks

|

$1,978 |

|

|||

|

392502-2-YG-T Vacuum Gauge, Micro-Ion Plus, Display, 2.75 in. CF, RS485, 2 Relays | $2,037 |

|

||||

|

392601-2-YG-T Vacuum Gauge, Micro-Ion Plus, 2.75 in. OD CF, DeviceNet, 2 Relays | $1,916 |

|

||||

|

Vacuum Gauge, Micro-Ion Plus, Display, 2.75 in. CF, DeviceNet, 3 Relays

$2,220

|

392602-3-YG-T Vacuum Gauge, Micro-Ion Plus, Display, 2.75 in. CF, DeviceNet, 3 Relays | $2,220 |

|

|||

|

392710-2-YG-T Vacuum Gauge, Micro-Ion Plus, 2.75 in.CF, EtherCAT, 2 Relays |

14 Weeks

|

$1,916 |

|

|||

|

392710-2-YE-T Vacuum Gauge, Micro-Ion Plus, NW25 ISO-KF, EtherCAT, 2 Relays |

14 Weeks

|

$2,129 |

|

Configuration Options

The following options are available for 392 Micro-Ion® Vacuum Pressure Transducers

Ordering Code Example: 392501-2-TE-T

| Configuration Option | Option Code |

|---|---|

Basic Micro-Ion Plus Modules |

|

| RS-485 interface no display | 392501 |

| RS-485 interface with display | 392502 |

| DeviceNet interface no display | 392601 |

| DeviceNet interface with display | 392602 |

| EtherCAT | 392710 |

Set Point Relays |

|

| Two (EtherCAT only available with two set point relays) | 2 |

| Three | 3 |

Ionization Gauge Filaments |

|

| Yttria-coated iridium | Y |

| Tungsten | T |

Vacuum Connections |

|

| NW16-KF | D |

| NW25-KF | E |

| NW40-KF | K |

| 1.33 in. (NW16-CF) ConFlat-type | F |

| 2.75 in. (NW35-CF) ConFlat-type | G |

| 0.5 in. VCR-type Male | H |

Measurement Units |

|

| Torr | T |

| mbar | M |

| Pascal | P |

The following options are available for 392 Micro-Ion® Replacement Sensor

Ordering Code Example: 392100-Y-E

| Configuration Option | Option Code |

|---|---|

Micro-Ion® Replacement Sensor |

|

| sensor | 392100 |

Ionization Gauge Filaments |

|

| Yttria-coated iridium | Y |

| Tungsten | T |

Vacuum Connections |

|

| NW16-KF | D |

| NW25-KF | E |

| NW40-KF | K |

| 1.33 in. (NW16-CF) ConFlat-type | F |

| 2.75 in. (NW35-CF) ConFlat-type | G |

| 0.5 in. VCR-type Male | H |

Specifications

-

Absolute Measurement Range1 x 10-9 Torr to atmosphere

1.33 x 10-9 mbar to atmosphere

1.33 x 10-7 Pascal to atmosphere

(air or N2) -

TypeVacuum Transducer

-

SensorMicro-Ion Ionization Sensor and Pirani Conductron Sensor

-

Operating Temperature10 - 40°C (50 - 104°F)

-

Maximum Bakeout Temperature05°C (221°F) maximum, with electronics removed

-

Storage Temperature-40 to +70°C (-40 to +158°F)

-

Analog OutputLogarithmic, 0.5 to 7.0 VDC, 0.5 V/decade

-

Internal Volume10.8 cc

-

Exposed Materials304 stainless steel, tantalum, tungsten, yttria-coated iridium, alumina, CuAg eutectic, Kovar, gold or nickel plated Kovar, borosilicate glass

-

Electronic Casing and FlangeAluminum Extrusion with Powder-coat

-

ComplianceRoHS, CE

-

FilamentTungsten or yttria-coated iridium

-

X-ray Limit3 x 10-10 Torr

4 x 10-10 mbar

4 x 10-8 Pascal -

Emission CurrentAutoranging

-

DegasElectron bombardment; 3 Watts for 1 minute/filament

Features

Analog Output and Digital Interface

The full range pressure measurement is output as a single analog signal or is available through optional RS-485, DeviceNet or EtherCAT digital interfaces. Up to three optional set point relays are available, they can be configured for process control with the ability to assign the relays at any pressure across a broad vacuum spectrum. The Series 392 Micro-Ion Plus is available with or without display, and can be configured with a wide variety of flanges.

Micro-Ion and Pirani Conductron Sensor Technology

The Series 392 Micro-Ion Plus combines Granville-Phillips® industry-standard and application-tested Micro-Ion ionization sensor with an innovative miniature Pirani Conductron sensor in a single gauge assembly envelope that is attached to a compact electronics control module. This compact modular design reduces the number of separate gauges, vacuum interfaces, cabling and control electronics that are typically required for full range pressure measurement. The full range pressure measurement is output as a single analog signal or is available through optional RS-485, DeviceNet or EtherCAT digital interfaces.

Integrated Gauge Assembly Electronic Memory

This second generation Micro-Ion Plus has integrated gauge assembly electronic memory that contains factory-calibration information. The electric memory is used by the control module to provide factory-level calibration accuracy for new and replacement gauges, and track gauge-tube usage information so the MKS service team can quickly understand your application environment. The miniature Pirani Conductron delivers improved accuracy through better thermal management within the gauge envelope. Finally, the Series 392 and Series 390 Micro-Ion ATM now share a common platform for improved product quality through high-volume manufacturing.

Field-Replaceable Gauge Assembly

The vacuum gauge assembly can quickly and easily be replaced in the field using only a screwdriver after removal from the vacuum system. Integrated electronic gauge assembly calibration information ensures replacement gauge accuracy and repeatability.

Accessories

Resources

Literature

- Vacuum Measurement Product Guide (711.5 kB, PDF)

- 392 Micro-Ion® Plus ATM Modules (241 kB, PDF)

Manuals

- 390, 392 Vacuum Transducer Pinouts (219.2 kB, PDF)

- 392 Micro-Ion® Plus Gauge Removal and Replacement Procedure (175.9 kB, PDF)

- 392 Micro-Ion® Plus Two-Sensor Combination Vacuum Gauge Module Manual (1.2 MB, PDF)

- 392 Micro-Ion® Plus Two-Sensor Combination Vacuum Gauge ModuleManual (1 MB, PDF)

- 392 Micro-Ion® Plus EtherCAT Manual (793.3 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity