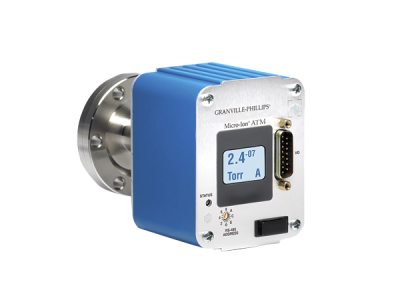

Vacuum Gauge, Micro-Ion Plus, Display, NW25 ISO-KF, RS485, 2 Relays

Model: 392502-2-YE-T

Vacuum Gauge, Micro-Ion Plus, Display, NW25 ISO-KF, RS485, 2 Relays

Vacuum Gauge, Micro-Ion Plus, Display, NW25 ISO-KF, RS485, 2 Relays

Model: 392502-2-YE-T

Overview

Overview

The 392502-2-YE-T Granville-Phillips® 392 Micro-Ion® Plus Vacuum Gauge Module features a NW25 ISO-KF fitting and RS485 communications. A digital display for local pressure readings is included. Two set point control relays are included to simplify process control functions. Settings are configurable through the RS-485 interface. It is a second generation full range pressure measurement module that combines industry-standard Micro-Ion® ionization vacuum gauge technology with a miniature Pirani Conductron heat-loss sensor to provide accurate, continuous pressure measurement from high vacuum to atmosphere. The 392 Micro-Ion® Plus Vacuum Gauge Module combines Granville-Phillips® industry-standard and application-tested Micro-Ion® ionization vacuum sensor with an innovative miniature Pirani Conductron vacuum sensor in a single gauge assembly with a compact electronics control module. The 392 Micro-Ion® Plus Vacuum Gauge Module compact modular design reduces the number of separate gauges, vacuum interfaces, cabling and control electronics that are typically required for full range pressure measurement. The full range pressure measurement is output as a single analog signal.

Technical Specs

-

Absolute Measurement Range1.0 x 10-9 to 760 Torr

-

Digital CommunicationRS485

-

TypeVacuum Gauge Module

-

DisplayGraphics LCD

-

InterfaceRS485

-

Relays2

-

Fitting TypeNW25 ISO-KF

-

Operating Temperature10 - 40°C (50 - 104°F), non-condensing

-

Maximum Bakeout Temperature105°C (221°F) with electronics removed

-

Storage Temperature-40 - 70°C (-40 - 158°F)

-

Relay Contact RatingMaximum 1 A at 30 VDC, Resistive load, Minimum 5 mA at 5 VDC, Resistive load

-

Power Requirements24 VDC +10% to -15%, 1 Amps, 22 Watts

-

Accuracy1 x 10-8 to 100 mTorr ±15% of Reading, 100 mTorr to 150 Torr ±10% of Reading, 1.33 x 10-8 to 0.133 mbar ±15% of Reading, 0.133 to 200 mbar ±10% of Reading, 1.33 x 10-6 to 13.3 Pa ±15% of Reading, 13.3 to 2.00 x 104 Pa ±10% of Reading (for Air or N2 Absolute Pressure)

-

Repeatability1 x 10-8 to 100 mTorr: ±5% of Reading, 100 mTorr to 150 Torr: ±2.5% of Reading, 1.33 x 10-8 to 0.133 mbar: ±5% of Reading, 0.133 to 200 mbar: ±2.5% of Reading, 1.33 x 10-6 to 13.3 Pa: ±5% of Reading, 13.3 to 2.00 x 104 Pa: ±2.5% of Reading (for Air or N2 Absolute Pressure)

-

Internal Volume10.8 cm3 (0.65 in3)

-

Exposed Materials304 stainless steel, tantalum, tungsten, yttria-coated iridium, alumina, CuAg eutectic, Kovar, gold or nickel plated Kovar, borosilicate glass

-

Electronic Casing and FlangeAluminum Extrusion with Powder-coat

-

ComplianceCE

-

FilamentYttria-coated Iridium

-

Response Time<25 mseconds

-

Connectors15-pin subminiature-D male

-

UnitsTorr

-

RS485 CommunicationsASCII: No parity, one stop bit

-

RS485 Address0-63, selected by using address switch and RS485 command

-

X-ray Limit<3 x 10-10 Torr, <4 x 10-10 mbar, <4 x 10-8 Pascal

-

Emission CurrentAutoranging

-

DegasElectron bombardment, 3 Watts for 1 minute/filament

-

Automatic Ionization Gauge On Setting2 x 10-2 Torr, 2.66 x 10-2 mbar, 2.66 Pa, with decreasing pressure

-

Automatic Switch to High Emission Setting5 x 10-6 Torr, 6.66 x 10-6 mbar, 6.66 x 10-4 Pa, with decreasing pressure

-

Automatic Ionization Gauge Off Setting3 x 10-2 Torr, 3.99 x 10-2 mbar, 3.99 Pa, with increasing pressure

-

Automatic Switch to Low Emission Setting1 x 10-5 Torr, 1.33 x 10-5 mbar, 1.33 x 10-3 Pa, with increasing pressure

-

Heat-loss Sensor WiresGold-plated tungsten

-

Maximum Inrush Current2 Amps, 48 Watts, for 0.5 seconds

Vacuum Gauge, Micro-Ion Plus, Display, NW25 ISO-KF, RS485, 2 Relays

Ultra-High Velocity

Ultra-High Velocity