MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

High Accuracy In-Situ Mass Flow Verifier

Overview

Enables "Wafer-to-Wafer" "Chamber-to-Chamber" & "Tool-to-Tool" Matching

The HA-MFV, High Accuracy Mass Flow Verifier is designed for use on process tools to verify mass flow control flow rates in-situ. Available with EtherCAT® or DeviceNet™ communications and measurement accuracy of 1.0% of reading, the HA-MFV can verify MFC flow with the actual process gas significantly better than older rate-of-rise devices or process chamber rate-of rise methods.

- 1.0% accuracy for wafer-to-wafer, chamber-to-chamber, & tool-to-tool process matching

- Supports multiple gas panels to reduce implementation costs

- 5 to 3000 sccm measurement range for a wide variety of processes

- In-situ assessment of MFC flow rate improves process control and avoids unneeded down-time

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

HA-MFV Mass Flow Verifier, 1% of Reading Accuracy, 5 - 3000 sccm |

|

Specifications

-

Mass Flow Verification Accuracy±1.0% of Reading

-

Mass Flow Verification Range5 - 3000 sccm (N2 equivalent)

-

Repeatability±0.5% of Reading

-

Reproducibility±0.3% of Reading

-

Pressure Range100 Torr

-

Pressure Accuracy0.25% of Reading

-

Proof Pressure45 psia

-

Burst Pressure150 psig

-

Minimum Penumatic Air Supply Pressure80 psig

-

Maximum Penumatic Air Supply Pressure100 psig

-

Span Temperature Coefficient<0.002% Reading/°C

-

Warm-up Time60 minutes

-

Operating Temperature10° to 40°C

-

Temperature Display0 - 100°C

-

Temperature Accuracy± 2°C

-

Temperature Resolution0.1°C

-

Storage Humidity0 to 95% RH non-condensing

-

Storage Temperature-20° to 60°C

-

Control InterfaceDeviceNet: 5-pin DeviceNet Micro Connector Type, EtherCAT: Dual RJ-45 (Comm.) M8 Male 5pin (PWR)

-

Diagnostic InterfaceEthernet RJ-45 female

-

Input Voltage11 to 25 VDC

-

Gas Supply FittingSwagelok® compatible 8-VCR® female, rotatable

-

Vacuum Supply FittingSwagelok® compatible 8-VCR® male type, rotatable

-

Pneumatic Air Supply Fitting1/8 inch one-touch quick connect tube

-

External Leak Integrity<1 x 10-9 scc/sec He

-

Wetted Materials316L SST passivated, Inconel, Incoloy

-

Seal Material316 SST nickel plated

-

Valve Seat MaterialPCTFE with Elgiloy® Diaphragm

-

Surface Finish<32 µ inches Ra

-

Dimensions6.98 x 10.0 x 10.0 in.

-

Weight23.9 lbs

-

ComplianceCE

Features

Sonic Flow Technology

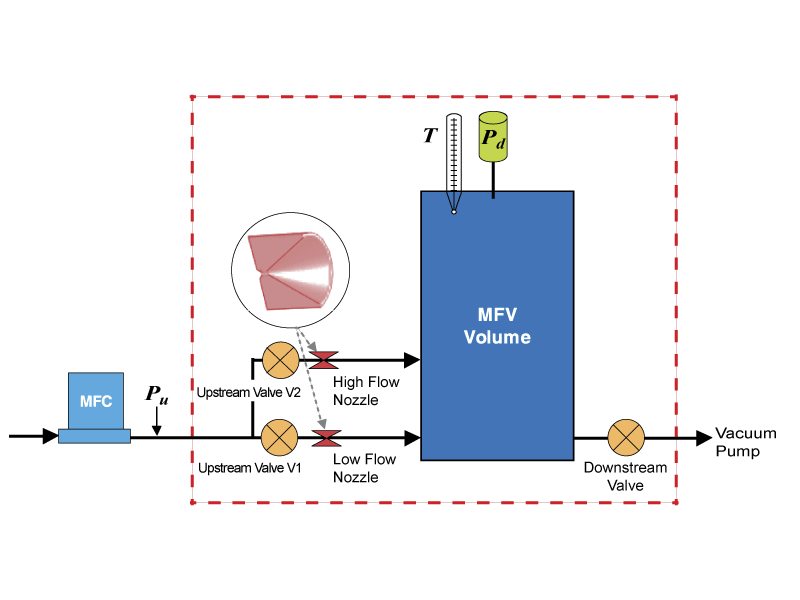

The insensitivity of the HA-MFV to external volume is realized through the use on sonic nozzle technology. The sonic nozzle creates a pressure drop and sonic flow conditions. In sonic flow, variations in pressure downstream of the nozzle have no effect on upstream conditions. Thus, the sonic nozzle effectively decouples the measurement in the HA-MFV from the upstream volume.

Better Measurement Accuracy

The HA-MFV is able to provide significantly better measurement accuracy and is insensitive to external volume (volume from MFC to the HA-MFV) conditions and variation. This insensitivity of the HA-MFV to external volume also results in more precise matching of measurements between HA-MFVs on multiple tools for the same process. This assures the user of precise tool-to-tool process matching.

Resources

Literature

- HA-MFV, DeviceNet™ High Accuracy Mass Flow Verifier Data Sheet (369.6 kB, PDF)

- HA-MFV, EtherCAT® High Accuracy Mass Flow Verifier Data Sheet (353.8 kB, PDF)

Technical Notes

Manuals

- HAMFV Technology Manual (10277599-001) (3 MB, PDF)

- HAMFV EtherCAT Module & Object Dictionary (20041006-001) (505.8 kB, PDF)

- HAMFV DeviceNet Profile Manual Supplement (663.6 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity