MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

SenseLink™ QM In-line Quality Detection

Overview

SenseLink™ QM data monitoring system provides an entire solution for process monitoring, fault detection, and part quality prediction utilizing multivariate analysis (MVA) technology. Adding MVA to your process will provide the highest level of process monitoring and fault detection attainable. All necessary data acquisition, multivariate processing, electrical and control functions come from a self contained, compact unit.

- Identify the quality of parts in-process

- Excellent multivariate prediction capabilities with existing machine sensors

- Reduce routine visual inspection costs by 33%

- Reduce number of exceptions by 50%

- Reduce Mean-Time-To-Detect (MTTD) by over 50%

- Reduce machine downtime by 5%

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

SenseLink-QM MVA Software, In-line Quality Detection, SenseLink |

|

Features

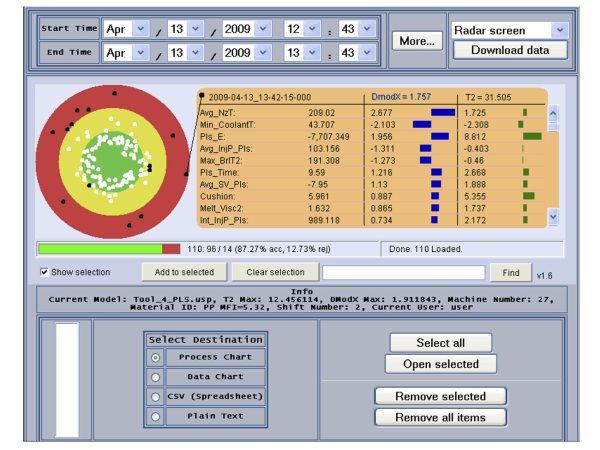

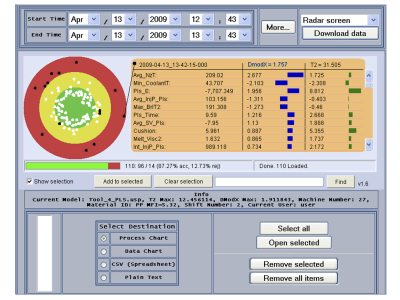

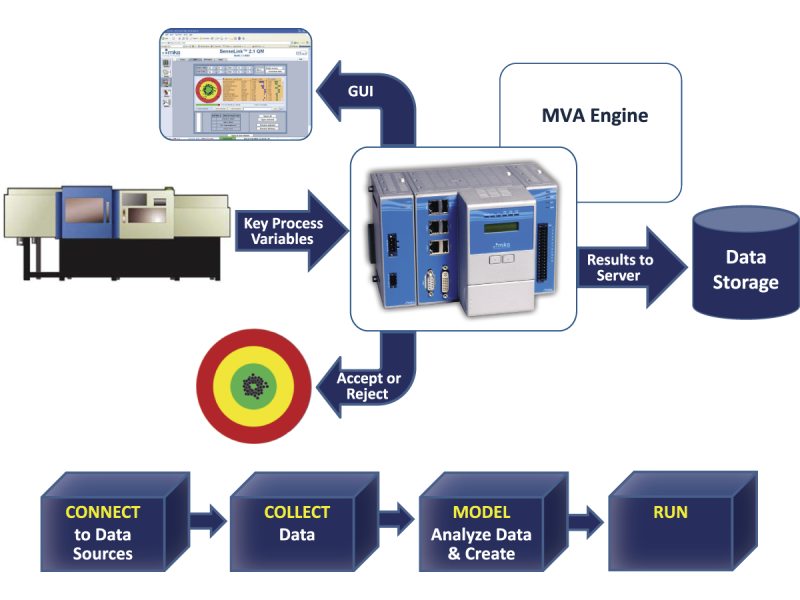

Integrates the Entire Multivariate Process

Only SenseLink QM integrates the entire multivariate process, from data collection to modeling to run-time control, into a single, compact package. The SenseLink QM hardware is designed as a highly integrated industrial computing platform, which can be mounted near almost any process. Process data can be acquired from analog, digital, and/or networked sources, and can be downloaded in chart, text, or CSV formats. All configuration and model creation are accomplished via a web browser user interface, requiring no software installation. Out-of-spec parts are diverted automatically, based upon alarm thresholds setup with the MVA results, eliminating the downstream costs associated with the acceptance of poor quality parts.

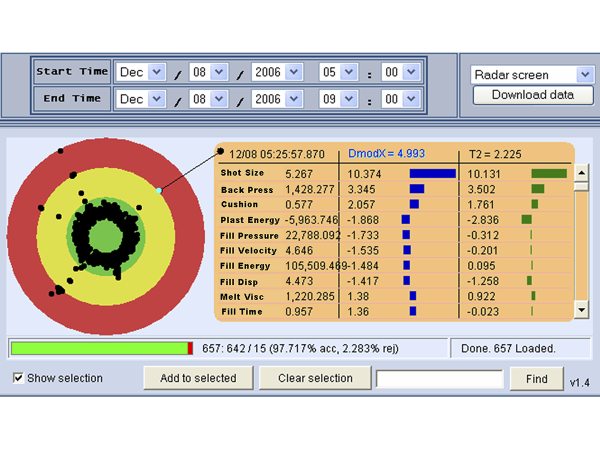

SenseLink™ QM Fault Detection

Contribution plots are shown in real-time to provide quick and easy process troubleshooting

Detecting faults in any process is only possible when the variables with the highest correlation to the final part quality are monitored. The SenseLink QM determines and calculates the most important features of all the process signals to accurately detect out of spec product and part quality defects.

A multivariate analysis is performed on all process variables, in real-time, and on each process cycle. The analysis may reject a part based on a variables value or, more importantly, on a change in correlation structure between a few variables or between multiple variables. The detection of variable relationship changes provides a tremendous improvement over typical univariate SPC methods used in manufacturing processes.

The SenseLink QM has been proven to detect faults based on out-of-spec critical part dimensions in industrial applications. Physical part quality defects include the following:

- flash

- short shots

- sink marks

- voids

- burning

- contamination

- weight

- bubbles

- surface appearance

- weld integrity

- poor seal bond

- imperfect granulation

- tablet density

- preform pearlescence

Multivariate Approach to Fault Detection

Contribution plots are shown in real-time to provide quick and easy process troubleshooting

This approach consists of creating a multivariate model that accurately predicts when a part is acceptable or out-of-spec, based on key process data. The value of the multivariate detection system is highly dependent on the multivariate model that is used to perform the analysis.

The recommended method and most common approach to creating a multivariate model is to run a short design of experiments (DOE). A well designed DOE can be run to establish a good process window and also to create structured variation in the data.

Once the DOE has been run, the SenseLink QM creates the model from the DOE data. All new data is then compared in real-time to the multivariate alarm limits established in the model, providing digital feedback to any auxiliary systems. Contribution charts are then shown in real-time which detail the variable or interaction of variables that were responsible for the deviation from the multivariate model. The results are available for web browser review and sent to local servers for storage. For slowly shifting or drifting processes, adaptive techniques can be included to allow the model to adjust to process changes. As a result false alarms are minimized.

- Summarizes multiple signals into easily understandable plots

- Process variables contributing to poor quality are easily identified

- Models can adapt to acceptable process changes resulting from material variation, equipment wear, environment, time, etc

- Reduced false alarms over typical univariate methods

- Ability to analyze multiple variables simultaneously

- Filters out process noise

- Correlation structure between all process variables is determined

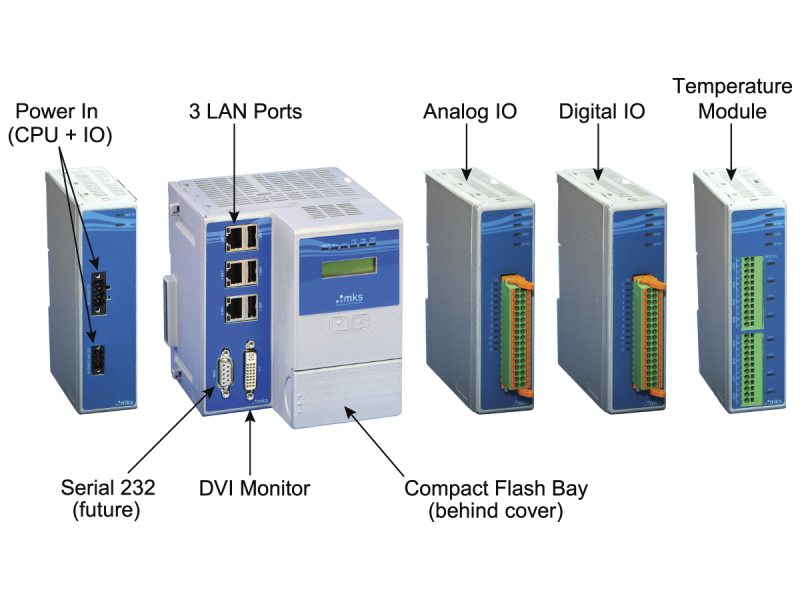

System Components

Each SenseLink QM system is contained within a single, compact data acquisition and computing module. The module consists of the MKS PAC hardware platform with the SenseLink QM multivariate analysis software. The SenseLink QM system can run up to 8 simultaneous MVA models.

The PAC platform CPU module, which runs the SenseLink QM, can interface directly with your own PLC over Ethernet and comes with a minimum size of 130 x 125 x 140 mm (W x H x D), with expandable common IO modules (analog, digital, temperature input) of 35 mm x 125 mm x 92.3 mm (W x H x D). The number of process variables which can be collected is potentially unlimited.

Applications

The SenseLink QM is a data acquisition system with a multivariate data analysis engine that was developed for any industrial manufacturing process, including primary or secondary operations to provide significant ROI benefits through improved process understanding, shortened process debug times, reduced scrap, and improved quality control. Applications include:

- Casting

- Molding – (Injection, Blow, Insert, Thermoset, LSR)

- Coatings Applications

- Ultrasonic and RF Welding

- Painting and other Secondary Operations

- Form, Fill, and Seal Operations

- Thermoforming

- Extrusion – Tube, Sheet, Film, etc

- Tablet Compression, Compounding

- Spectral Analysis

- Assembly Operations

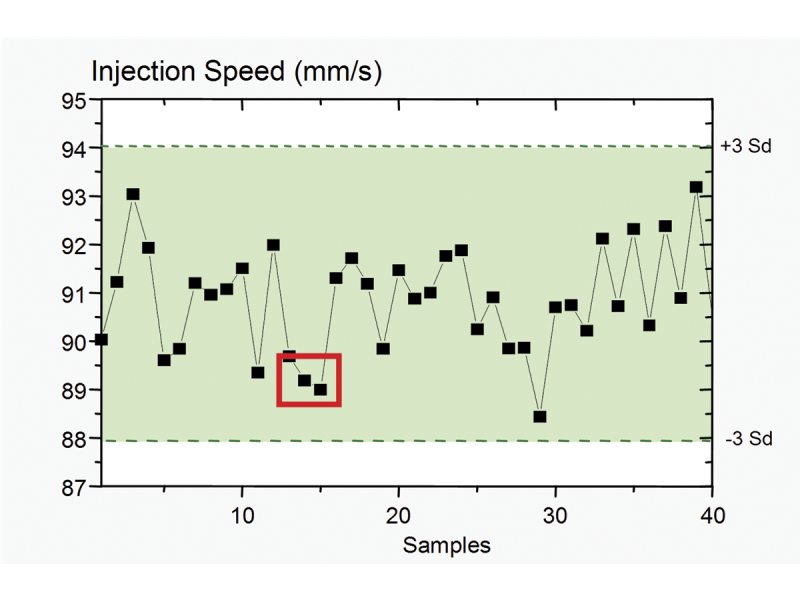

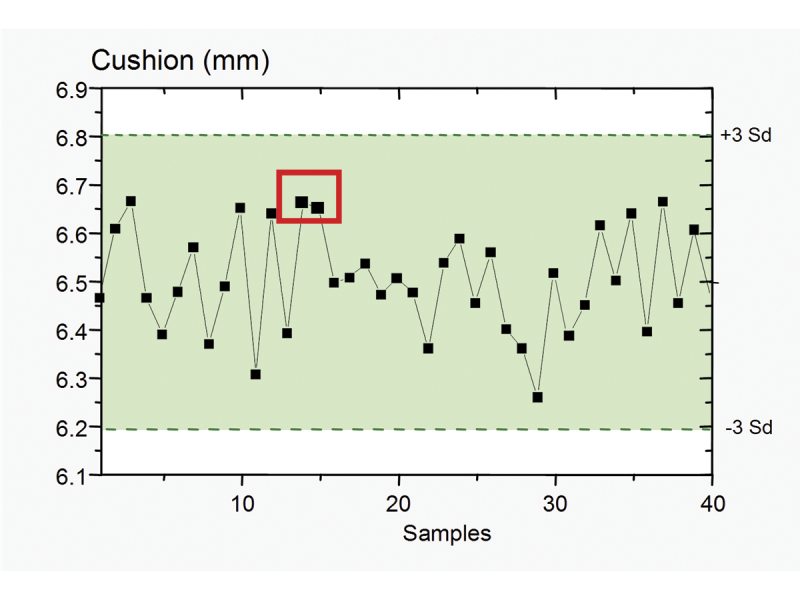

Correlation Structure Example

Changes detected in the relationships between variables shown. Individual variables shown below.

Resources

Application Notes

- Optimization of Injection Molding Processes Using Design of Experiments (1.2 MB, PDF)

- Real-Time Monitoring, Fault Detection and Reporting (1.4 MB, PDF)

- Real-Time Fault Detection Using SenseLink™ QM (707.6 kB, PDF)

- ROI Benefits of SenseLink™ QM in Injection Molding Applications (247 kB, PDF)

- Process and Product Optimization in Extrusion Using Machine Learning and Multivariate Analytics (1,018.9 kB, PDF)

Manuals

- SenseLink™ QM 2.2 Multivariate Fault Detection User Manual (4.8 MB, PDF)

- SenseLink™ QM 2.4 Multivariate Fault Detection User Manual (4.6 MB, PDF)

- SenseLink™ QM 3.1 User Manual (6.6 MB, PDF)

Literature

Other

- Leveraging Advanced Analytics for Improved Fault Detection in Discrete Manufacturing Processes (1.5 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity