MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

AX8580 Fully Integrated Modular Ozone Delivery System

Overview

The AX8580 Ozone Delivery System generates and delivers high flow, high concentration, ultra-clean ozone for advanced thin film applications. The AX8580 is specifically designed for use with an increasing number of semiconductor process applications such as ALD, CVD and TEOS/Ozone CVD.

- Fully integrated, modular system equipped with up to (4) AX8415 generators for the highest concentration at the highest flow

- Individually controlled generator outputs support up to (4) channels or combined into a single channel chamber process tool

- Highest ozone concentrations >400g/Nm3 at the highest flow rates for improved thin film quality

- Improved operating performance and extended lifetime due to cooling improvements and optional in-rack chiller

- Compatible with or without nitrogen for ultra-clean ozone

- Optional integrated ozone destruct for protection from unintended ozone exposure

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

AX8580 Ozone Delivery System, 50 slm per channel, Fully Integrated Modular |

|

Specifications

-

TypeOzone Gas Delivery System

-

Ozone Output>400g/Nm3

-

Flow Rate2.5 gpm per generator

-

Feed GasOxygen, Nitrogen

-

Feed Gas Supply Pressure70 ±2 psig (483 ±13.5 kPa, 4.92 ±0.14 kg/cm2) nominal, 80 ±2 psig (551 ±13.5 kPa, 5.62 ±0.14 kg/cm2) maximum N2 pressure 10 psi higher than O2 pressure

-

Feed Gas Purity99.9995% minimum

-

Operating Temperature5 - 40°C (41 - 104°F)

-

Cooling Water Temperature Required5 - 17°C

-

Cooling Water Filtration Required100 microns

-

Cooling Water Quality Required1 - 3 MΩcm DI

-

Cooling Water Minimum Flow Required2.5 gpm per generator

-

Cooling Water Connections Required1 in. compression (Swagelok®)

-

Cooling Water Heat Load Required5 kw per generator

-

Voltage Requirements208 volts AC (±10%), three phase

-

Current Requirements65 Amps max (fully populated system)

-

Frequency50/60 Hz

-

Exhaust Flow RateTwo-generator system requires 125 CFM (3.5m3/min), Four-generator system requires 250 CFM (7m3/min), Static Pressure 125CFM (3.5m3/min) requires 0.1 in. H20 minimum (25 Pa), measured 3 ft inside the customer provided exhaust air duct, 250 CFM (7m3/min)

-

Exhaust TypeSEMI Category 4 (accidental or emergency release of hazardous gas or vapor)

-

Exhaust Static Pressure0.07 in. H20 minimum (17.4 Pa), measured at duct entrance to cabinet

-

Control Air Pressure70 - 100 psig (483 - 689 kPa)

-

Control Air TypeCDA or dry nitrogen, 40µ filtered

-

Control Air Fitting0.25 in. compression (Swagelok®)

-

Exhaust Connection6 in. diameter duct opening standard

-

Dimensions26 x 82 x 38 in. (661 x 2083 x 965 mm) (width x height x depth)

-

Relative Humidity30 - 90% (non - condensing)

-

Weight705 lbs (320 Kg) for system with one generator 1 channel and BMT safety monitor, 1015 lbs (461 Kg) for system with four generator 1 channel and BMT safety monitor, 1045 lbs (480 Kg) for system with two generator 1 channel and BMT safety monitor and chiller

-

ComplianceETL 9700614, SEMI S2-0715

-

AltitudeUp to 1000 m (3280 ft) above mean sea level

Features

Environmentally Friendly Solution

Ozone has many advantages over other oxidizers as a strong oxidizing agent. Ozone has a high redox potential, can be generated at the point-of-use, and it decays naturally into oxygen (2O3 ⇒ 3O2). Therefore, it is considered a "green" chemical. If required, ozone can also be destroyed at the output of the process chamber using a catalytic or thermal destruct unit. This significantly lowers the chemical disposal cost, as the output is oxygen and contains no ozone. Ozone is very stable at room temperature, making it a good choice for most applications. Typical ozone applications include atomic layer deposition (ALD), chemical vapor deposition (CVD), photoresist strip, wafer cleaning, contaminant removal, surface conditioning, and oxide growth.

Multi-channel Capability

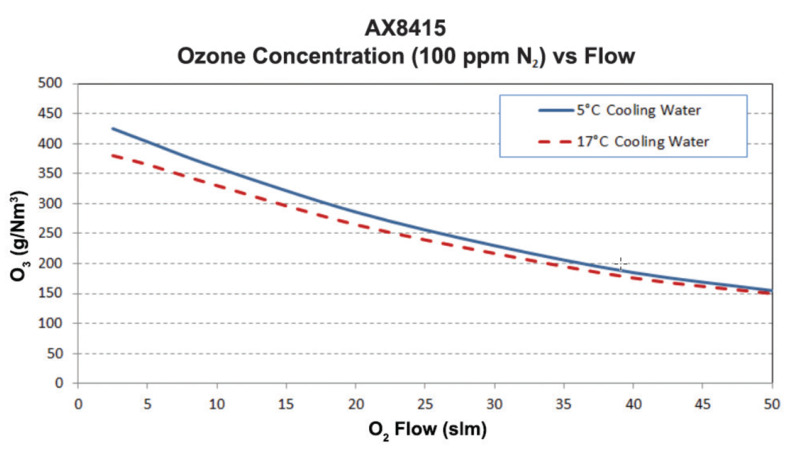

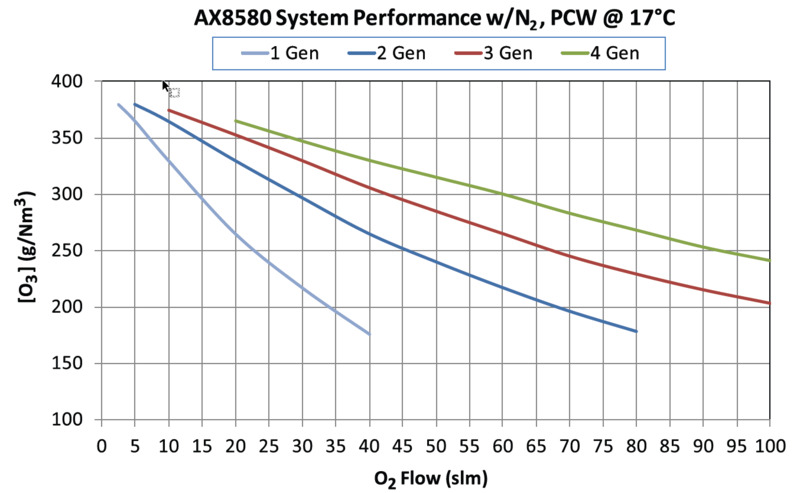

The AX8575 system is configurable with up to four (4) independent channels to support multiple tools or chambers concurrently. Each channel can be matched to the specific concentration and flow required for your specific process. For ultra high concentration processes the system can be configured for up to two (2) channels with an in-rack chiller thereby maintaining the same footprint. The ozone source for each channel is the production-proven AX8415 series ozone generators. It incorporates MKS patented, field proven, high concentration, ultra clean ozone generation technology. The AX8580 includes all subassemblies required for stand-alone operation, including power distribution, an ambient ozone safety monitor and status indicator panel. For ozone performance of each output channel, refer to Figures 1 and 2.

Resources

Literature

- AX8580 Fully Integrated Modular Ozone Delivery System (633.4 kB, PDF)

Drawings & CADs

- AX8580 Ozone Delivery System Dimensional Drawing (825.4 kB, PDF)

Application Notes

- Ozone Data Conversion Tables (289.1 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity