MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

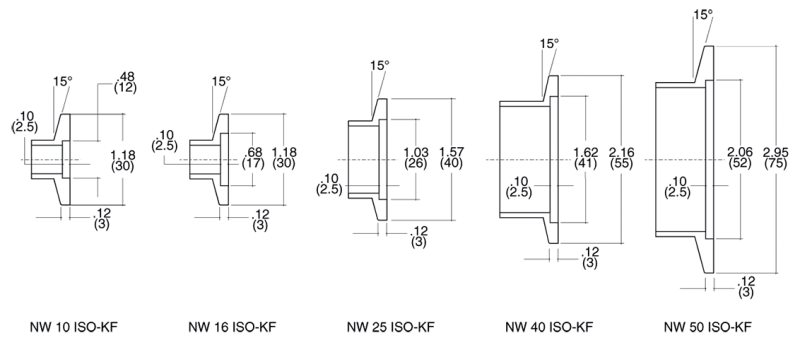

ISO-KF Stainless Steel Short Weld Stub Vacuum Flanges

Overview

- 13 or 19 mm butt-weld stub

- 304 Stainless Steel construction

- NW10 to NW50 flange sizes

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

100310300 ISO-KF Weld Stub Flange, NW10, 0.5 in. Tube OD, 0.5 in. Length, 304 S.S. |

1 Week

|

$12.51 |

|

|||

|

100310301 ISO-KF Weld Stub Flange, NW16, 0.5 in. Tube OD, 0.5 in. Length, 304 S.S. |

1 Week

|

$12.51 |

|

|||

|

100310303 ISO-KF Weld Stub Flange, NW25, 1.0 in. Tube OD, 0.5 in. Length, 304 S.S. |

In Stock

|

$14.58 |

|

|||

|

100310305 ISO-KF Weld Stub Flange, NW40, 1.5 in. Tube OD, 0.75 in. Length, 304 S.S. |

In Stock

|

$18.98 |

|

|||

|

100310306 ISO-KF Weld Stub Flange, NW50, 2.0 in. Tube OD, 0.75 in. Length, 304 S.S. | $29 |

|

||||

|

100310311 ISO-KF Weld Stub Flange, NW16, 0.75 in. Tube OD, 0.5 in. Length, 304 S.S. |

1 Week

|

$12.51 |

|

Specifications

-

Component TypeShort Weld Stub Vacuum Flange

-

SeriesSeries 31

-

Material304 Stainless Steel

-

Flange TypeISO-KF

-

Wall Thickness0.065 in. (1.7 mm)

Features

ISO-KF Standard Interface Dimensions

The International Standards Organization (ISO) has defined the interface dimensions, allowing the interchanging of components that conform to the ISO-KF standard’s dimensions. The ISO-KF system is a modular, building block method of creating a vacuum piping system. There are several advantages in the use of ISO components. Since component dimensions are standardized, elbows, tees, crosses or valves for a given size may be interchanged. The flanges are ''sexless'' and the seal is symmetrical, so that the components are rotatable. By using ISO components, system assembly is quick and cost effective. The Series 31 component line also includes a few components in NW 80 (3'') and NW 100 (4'') sizes. There is no international standard for these sizes in the KF style. MKS has designed the flanging using series consistencies and customer requirements.

Joining ISO-KF Flanges

The ISO-KF components are assembled by inserting a centering ring between the two flange faces, then securing the assembly with a flange encompassing clamp.

There are a variety of clamp choices in the Series 31 line. The wing-nut clamp is hand tightened until metal contact is felt. A version of the wing-nut clamp with a washer is also available. The toggle clamp is convenient and easy to use. The clamp provides enough sealing force to fully compress the O-Ring, so that the flanges and the centering ring are metal to metal. The heavy-duty spring supports the full range of production tolerance variables. The self-adjusting clamp locks in a positive method. A pin can be inserted to prevent accidental release of the toggle lever. The toggle clamps are ideal for situations where the clamp must be removed frequently, like leak testing or gauge calibration. The Series 31 ISO-KF line also includes bulkhead clamps. They are used to attach an ISO-KF flange directly to a chamber or base plate. The two-part, bolted clamp fits over the flange. A centering ring assembly is needed between the flange and the opening. The bulkhead clamp kit includes the two-piece clamp, bolts and washers.

Positive Pressure Applications

If system pressures are in the positive pressure range, it is recommended that over pressure rings are used. The ISO-KF over pressure rings are installed differently by size. The NW 16, 25, and 40 ISO-KF rings are installed over the two ISO-KF flanges. The NW 10 and 50 ISO-KF rings are installed between the two flange faces. The clamp is installed around all items to secure the assembly.

ISO-KF Pipe Fitting Applications

ISO-KF fittings can be used in a wide variety of applications including:

- Roughing and foreline plumbing

- Systems requiring frequent cleaning or modification

- Research and teaching laboratories

- Small systems

ISO-KF components are primarily designed for use at subatmospheric pressure. Because of the large number of elastomer seals used, typical limiting pressure without baking is about 10-7 Torr. Baked systems using Viton® seals can be used to two decades lower.

Resources

Literature

- Series 31 ISO-KF Vacuum Components & Fittings (1.1 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity