MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

New AMDS-1000 Arc Monitoring and Detection System

Overview

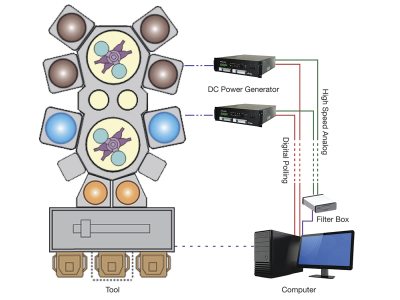

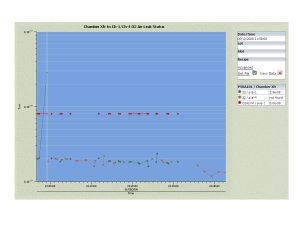

MKS' AMDS-1000 system prevents equipment damage and improves wafer yield during Physical Vapor Deposition (PVD) processing by providing fast, reliable and comprehensive plasma monitoring and detection of arcing events. The AMDS-1000 family has models that monitor arc events lasting a few microseconds, detect hard arcs lasting over 100 microseconds, and provide combined arc monitoring and detection capability during the entire plasma process.

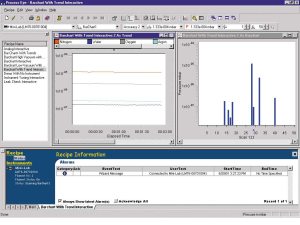

All models connect to the DC generator to poll arc events, gather power information, and support 1-4 chambers per tool. MKS' Process Eye™ Professional Residual Gas Analyzer software handles data acquisition, interpretation, recall and intelligent alarming when used with the AMDS-1000 system. MKS' TOOLweb® supports full alarm and data reporting to the fab and Fault Detection and Classification (FDC) of micro and hard arcs during PVD processes including but not limited to Al pad PVD, hard mask PVD, and Cu seed/barrier PVD.

- Improve wafer yield and reduce tool damage through production

- Reduce false alarms

- User configurable recipe wizard supports customized warnings and alarms

Products

Configuration Options

| AMDS-1000D | AMDS-1000A | AMDS-1000AD | |

|---|---|---|---|

| Capability | Monitor micro and hard arc events | Detect hard arcs using high-speed DAQ | Detect micro and hard arcs during the entire plasma process |

| Connection Type | Digital port | Analog interface | Digital port & analog interface |

| Maximum Sampling Frequency | Up to 10Hz | Up to 250KHz | Up to 10Hz for digital, 250KHz for analog |

| Channels per Chamber | Five (micro arc, hard arc, power, voltage and current)* | Two (voltage, power) | Seven (five for digital*, two for analog) |

| Chambers per Computer | 4 | 4 | 4 |

| Signal Cable** | RS232 | Ethernet | RS232, Ethernet |

| * Varies with the generator. ** Cable length for RS232 and Ethernet is 30 meters. |

|||

Features

- Analog, digital and combined communication protocols

- Ability to detect micro arcs lasting several microseconds and hard arcs over hundred microseconds

- Analyzes arc data and extracts severity and magnitude in real-time

- Monitors or detects arcs in the whole plasma processing including plasma ignition and power transition

- Multiple chamber support

- Works with MKS Process Eye Professional Residual Gas Analyzer software for data acquisition, interpretation, recall, and intelligent alarming

- Provides automated monitoring of semiconductor tools when combined with TOOLweb RGA software

Resources

Literature

- AMDS-1000 Arc Monitoring and Detection System (259.6 kB, PDF)

Application Notes

- AMDS-1000 for PVD Arc Monitoring and Detection (421.1 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity