MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

Dissolved Carbon Dioxide (DI-CO2) Ultrapure Water Delivery System

Overview

The DI-Solver™ CO2 is used in single substrate cleaning tools for rinsing steps to prevent ESD effects and/or metallic corrosion. By adding carbon dioxide to UPW (ultrapure water) conductive DI-CO2 water (carbonated DI-water) is created, which prevents surface charging. Dissolved carbon dioxide provides optimal cleaning capability in an acidic chemistry, improving cleanliness. The prevention of ESD effects reduces structural damage such as punch through holes, arcing and improves yield.

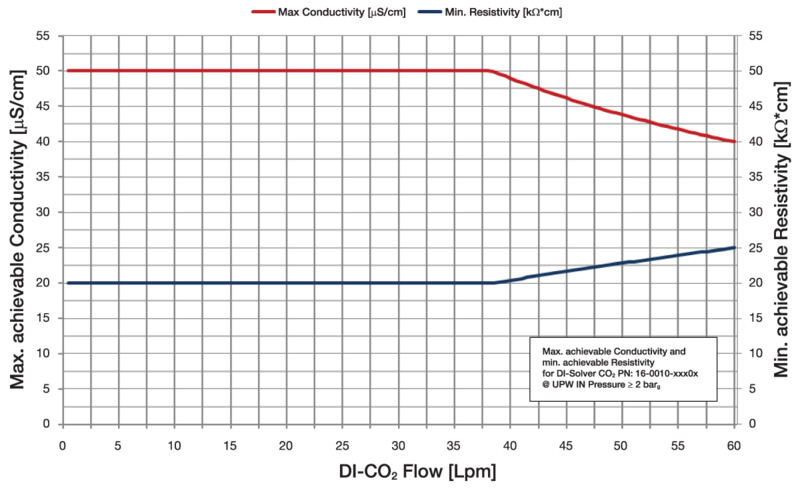

The DI-Solver system is designed to deliver dissolved carbon dioxide with a constant conductivity at different flow rates for single or multiple applications simultaneously. Operated within the specified ranges, the typical conductivity control accuracy for a stable dissolved carbon dioxide flow differs less than 5% from setpoint.

- Precise gas dosage through proprietary mass flow controller system

- Precise conductivity control in range from 5 to 50 μS/cm

- Up to 60 lpm flow

- Repeatable unit to unit performance

- Field proven sub-components life

- Maintenance free

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

DI-CO2 Water Delivery System, Ultrapure Carbon Dioxide Water |

|

Specifications

-

TypeCarbon Dioxide Ultrapure Water Delivery System

-

Flow RateMinimum total flow: 0.5 L/min (0.1 gpm)

Maximum total flow: 60L/min (15.8gpm) -

CommunicationBinary in/out (dry contacts)

RS232, analog out

USB -

Power Requirements24 VDC/60W

-

AccuracyTypical maximum deviation from set point:

Steady state flow: ±3%

Fluctuating flow: ±10% for flow changes <4 L/min per sec -

UPW Temperature Range20 - 50°C

-

Outlet Pressure1.0 - 3.0 barg (0.1 - 0.3 MPag, 14.5 - 43.5 psig), depending on UPW supply pressure

-

Conductivity/Resistivity RangeMinimum conductivity 5 µS/cm, max. resistivity 200 kOhm*cm

Maximum conductivity 50 µS/cm, min resistivity 20 kOhm*cm -

Plumbing MaterialsLiquid contacted surfaces: PFA, PVDF

-

Cabinet MaterialPVDF or C-PVC or FRPP

-

Dimensions386 x 650 x 232 mm (WxHxD)

-

Weight17.3 kg

Features

MKS’ DI-Solver CO2 is a component-based system to be integrated into a tool. It fully meets the demands of the semiconductor industry by using only high purity standard materials and safety features. The units provide a conductivity range from 5-50 μS/cm at 0.5-60 liters/min.

- Best dynamic conductivity control and accuracy at point of use from proprietary control of gas

- Increases yields by inhibiting Electrostatic Discharge

- Small compact module for easy integration

- Low operating costs, no CO2 or UPW consumption during process pauses

Resources

Literature

- DI-CO2 Compact Carbon Dioxide Ultrapure Water Delivery System (251.6 kB, PDF)

Drawings & CADs

- DI-CO2 Dimensional Drawing (140.4 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity