Transforming Lithium-Ion Battery Manufacturing and Performance

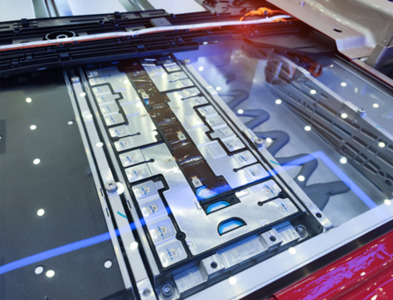

E-mobility offers tremendous opportunities, but expectations are equally high. MKS is an industry leader in developing key technologies that drive automotive innovation in battery manufacturing. Our advanced surface finishing technologies, high-end photonics solutions and world-class measurement systems enable you not only to optimize both new and existing production processes but also to improve battery performance, safety and reliability.

Innovative Lasers and Photonics Solutions Enabling Next-Generation Battery Design

With over 50 years of experience providing components and expertise for thousands of laser systems in a variety of markets, MKS is a long-term partner to several Li-ion battery manufacturers. We offer a full range of products including lasers for foil and separator cutting of next generation batteries, fast, high-power laser measurement and profiling as well as optics and opto-mechanics to maximize throughput and manufacturing yield, and improve battery performance.

Learn More

Leading Surface-finishing Solutions for EV, HEV and PHEV Batteries

Battery manufacturers strive to achieve an effective range for electric vehicles that is comparable to internal combustion engine automobiles. Innovative battery developments focus on new, active materials or thinner current collector foils that require novel, viable manufacturing processes and surface treatment methods. We offer perfectly matched processes for every step of surface finishing application; from pretreatment to final sealing. Our surface-finishing solutions minimize corrosion on every battery component, enable superior connectivity while resisting wear, improve adhesion, and ensure secure fastening.

Learn More

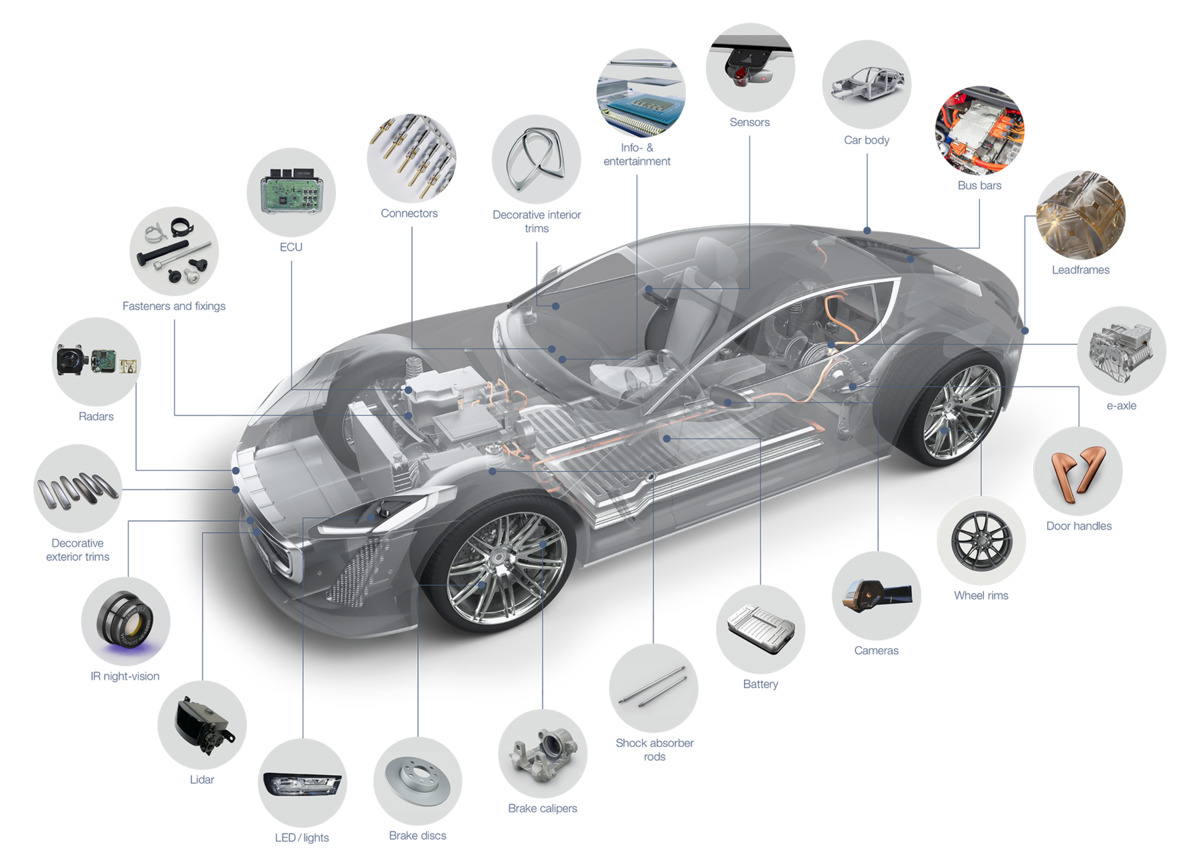

As a long-standing and reliable partner to the automotive industry, MKS has a deep understanding of the requirements of automotive manufacturers and their suppliers.

With our profound expertise in decorative and functional surface finishing, Lidar and night vision sensors and optics, laser beam measurement and characterization products, we enable our customers to drive next generation mobility.

Learn More

Atotech® Surface Finishing Solutions

Innovative and sustainable surface finishing systems

We pay special attention to the needs and demands of automotive manufacturers, OEMs and their suppliers. This makes us an ideal partner for the automotive industry. Our understanding of the industry’s needs – in combination with our remarkable plating and surface finishing expertise – allows us to offer tailored solutions that meet the demanding performance and design requirements of the industry. Learn More

From pretreatment to final sealing, our comprehensive range of surface finishing solutions brings enhanced connectivity, longer lifetimes, improved adhesion, and outstanding reliability for EV, HEV and PHEV batteries. Experience unparalleled battery safety, operational lifetime, and boosted performance. Learn More

Our portfolio for the automotive industry includes solutions for the entire spectrum of decorative and functional surface treatment, metallization and plating technologies for all drive technologies. Many of our Atotech products are approved by numerous automotive manufacturers worldwide. Learn More

Product Finder for Functional and Decorative Surface Finishing

Product Finder for Electronics Surface Finishing Solutions

MKS Vacuum Solutions

High precision testing capabilities

The automotive landscape is changing. New and evolving engine technologies and tighter environmental controls place new challenges on automotive manufacturers and OEMs. Our gas analyzers provide precise speciation of gases in combustion and EV engines and support safer Li‑ion battery development. MKS pressure measurement devices test cabin integrity, detecting leaks that negatively impact mileage. Read More

MKS ICE testing gas analyzer provide engine manufacturers and testers comprehensive insight into exhaust composition ensuring pollutant and GHG regulations are met.

MultiGas™ 2030 FTIR Gas Analyzers

MKS gas analyzers for EV battery testing measure the concentration of multiple gases emitted during an event, in real time, enabling development of new and safer battery designs.

MultiGas 2030 FTIR Gas Analyzers

MKS differential manometers for cabin air integrity testing are used to test vehicle cabin leakage, providing vehicle manufacturers insight into cabin air integrity.

Ophir® Laser Measurement Solutions

Enhance process quality in industrial production lines

Laser light and the automotive industry are closely tight together. High-power laser-based manufacturing plays a key role in automotive welding, cutting, brazing, marking and cleaning. Understanding and ensuring the quality of the laser beam is the first step towards high product quality and sustainable processes. Learn More

BeamWatch® Integrated Measurement Systems 150/500 are fully automated laser measurement systems designed to integrate the measurement of critical laser beam parameters in industrial production lines. Based on BeamWatch’s patented, non-contact profiling principle, BeamWatch Integrated offers contactless and simultaneous measurement of all critical laser beam parameters in real time, while its built-in power meter delivers absolute power readings.

BeamWatch Integrated 500 Caustic and Power Laser Measurement System

BeamWatch Integrated 150 Caustic and Power Laser Measurement System

Helios Plus is an all-in-one sensor for industrial applications featuring 'power from pulse' measurement of up to 12kW without water cooling. Helios Plus provides Profinet and RS232 or Ethernet/IP and RS232 communication. With its industrial interfaces, the Helios Plus power measurement device is designed to be integrated in automated production lines. Especially in critical production processes such as battery production the laser power can be measured within seconds to ensure the quality of the produced parts.

Helios Plus Industrial Laser Power Sensor

The IPM-10KW is a modular industrial sensor for measuring the average power of high-power lasers up to 11kW. The measurement device is robust, offers industrial interfaces and connectors as well as an interlock output to protect the sensor from overpower or cooling water failure. For extra protection, the user can order the IPM-Shutter10 which provides an automated shutter with a field replaceable anti-reflective coated window. The measurement device can be integrated easily in modern automation systems by using the additionally available IPM-COM communication module (EtherNet/IP and Profinet).

Ophir® Optics Solutions

Maximized Night Vision Performance and Road Safety

For maximum performance and minimal collision risk, our Ophir athermalized lenses offer high accuracy in all environmental conditions while also featuring a compact size, and competitive costs.

Newport® Precision Motion and Measurement Solutions

Proven performance, expertise and experience

Hexapods are creative and effective solutions to complex motion applications that require high load capacity and accuracy in up to six independent axes. To manufacture Advanced Driver Assistance Systems (ADAS) camera, sensor and lens must be aligned in 3D space. This requires the maximum precision achieved by Newport hexapod motion controllers delivering the best focus and image clarity possible. Newport hexapods are also utilized to align the optical components of LiDAR sensors and assemblies. With our Newport precision motion control, LED sources are aligned to the lens assembly and with 6-axis adjustment capability can be performed on a bank of LEDs. Additionally, our sophisticated Newport motion solutions precisely position the components. Read More

Our Newport precision motion products simplify the laser-based machining processes to cut the glass for displays, while tip/tilt stages are used to adjust beam delivery angles for surface coating processing. Read More

The URS family of rotation stages provides 360° continuous motion in a low profile package and is suitable for research and industrial applications needing precision performance at an affordable cost. Read More

Motorized goniometric cradles for a wide variety of rotation applications. Our goniometers feature a direct mounting capability that saves set-up time, design time, and adapter plate costs. Read More

Spectra-Physics® Laser Solutions

Precision laser cutting for Li-ion battery and display manufacturing, high endurance sophisticated automotive PCB processing, and aesthetically attractive and permanent laser marking for components and controls

Spectra-Physics industrial OEM laser products, with pulses from short-nanosecond to ultrashort picosecond and femtosecond regimes at higher powers, offer unprecedented flexibility in tailoring the output intensity in time, enabling high-throughput manufacturing of resilient, high-performance batteries.

IceFyre® FS | IceFyre | Talon® Ace™ | Talon

Spectra-Physics ultrashort pulse lasers are proven glass-cutting solutions, able to process contoured shapes in a variety of glass types and thicknesses. Their unique architecture for flexible pulse tailoring enables process fine-tuning to accommodate dynamic processing environments while maintaining best cut quality. Our Newport precision motion products simplify the laser-based machining processes to cut the glass, while tip/tilt stages are used to adjust beam delivery angles for surface coating processing.

Spectra-Physics nanosecond and picosecond UV and Green lasers, such as the Talon Ace and IceFyre provide a wide range of processing high-end/high endurance PCBs and Flex-PCBs the demanding needs of automotive electronics.

Using our Spectra-Physics ultrashort pulse lasers, with an ultraviolet (UV) wavelength in particular, such assemblies can be cut in variable and contoured shapes with industry-leading quality and throughput. These systems are vital for safe driving conditions.

Spectra-Physics Explorer® and Talon lasers feature the shorter green and UV wavelengths, which enables precise and permanent marking on a wide range of automotive products, from plastics to metals. For part identification to advanced visual usage in displays and human interactive controls, these lasers provide aesthetically appealing marks with uncompromised reliability.

Ultra-High Velocity

Ultra-High Velocity