Wafer Surface Cleaning Solutions

Prior to a wafer's entry into the fabrication process, its surface must be cleaned to remove any adhering particles and organic/inorganic impurities. Cleaning is a critical process step. Contamination on the wafer surface can cause unreliable electrical properties leading to defective, poor quality semiconductor chips. Continually shrinking device design rules have made cleaning technologies ever more important to achieving acceptable product yields. In modern device fabrication, wafer cleaning procedures can make up 30-40% of the steps in the total manufacturing process.

MKS solutions for wafer cleaning include microwave, plasma, ozone, and process automation products.

Learn More:

MKS Handbook Second Edition

Semiconductor Devices and Process Technology

Detailing the fundamental device physics, materials, and fabrication processes used to manufacture semiconductors.

A free book from MKS

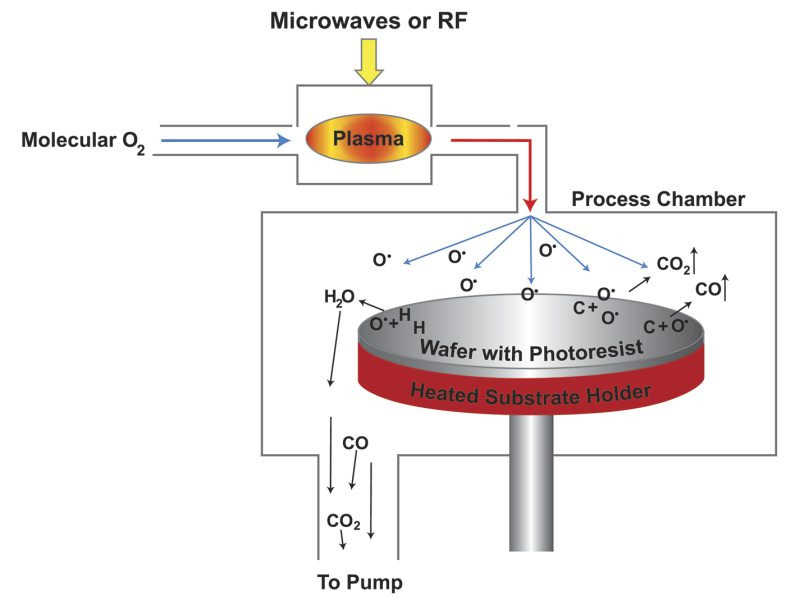

Wafer Surface Cleaning

A detailed discussion of wafer surface cleaning processes.

Microwave Generators and Systems

Compact industrial microwave generators and systems that are adaptable to a wide range of applications including various wafer surface cleaning processes.

Remote Plasma Sources for Process Applications

MKS remote plasma sources deliver high density reactive radicals improving on-wafer cleaning and deposition throughput.

Dissolved Ozone

The high redox potential of ozone causes rapid conversion back to oxygen making it an environmentally friendly alternative to other chemical processes.

Automation Controllers and Modules

Automation controllers and modules are the building blocks that can be configured to provide specific functionality meeting the custom requirements of wafer surface cleaning applications

Ultra-High Velocity

Ultra-High Velocity