Chemical Mechanical Planarization Solutions

Chemical mechanical polishing (CMP) is a planarization technique that was developed for semiconductor applications in the late 1980s and early 1990s. During this period, the number of metal layers increased dramatically and device topographies began to exhibit features that inhibited conformal deposition and gap fill by photoresist, metal, and insulator films.

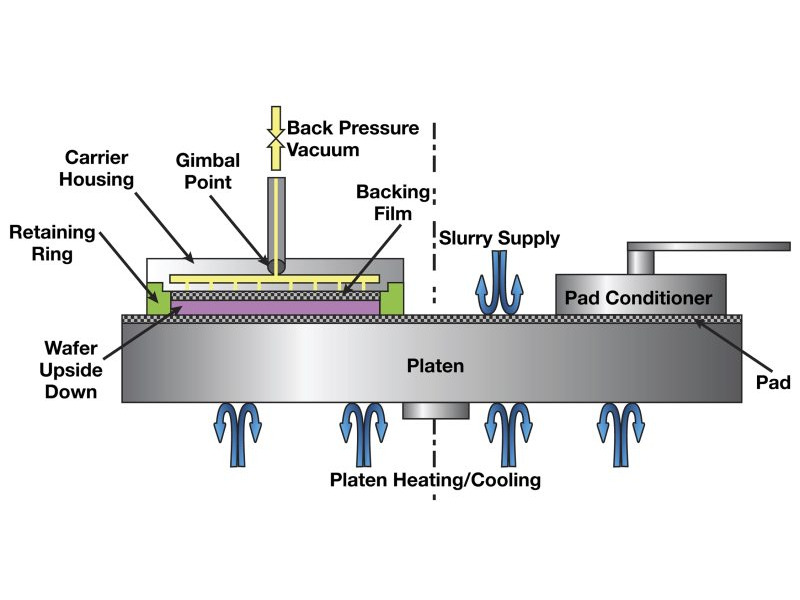

MKS's Pressure Control products can be applied in the systems that control the backing pressure applied to the wafer holder. Pressure/Flow Controllers can be used with different MKS gas flow control valves to control the backing gas pressure on wafer carriers in CMP tools with pressures ranging from vacuum up to 100 psig.

Learn More:

MKS Handbook Second Edition

Semiconductor Devices and Process Technology

Detailing the fundamental device physics, materials, and fabrication processes used to manufacture semiconductors.

A free book from MKS

Chemical Mechanical Planarization

A detailed explanation of the CMP process.

MKS Pressure Controllers & Valves

Best-In-Class Vacuum Control Solutions used in CMP processes

Upstream Flow Control Valves

Providing proportioning control valves designed for precise control of gaseous flows upstream in the process.

Ultra-High Velocity

Ultra-High Velocity