Mass Spectrometry Analyzer Care and Repair

Many times, residual gas analyzers need to be operated in harsh environments to analyze or control a process. Inadvertent exposure to atmosphere, pump oils or other contaminants also happens in spite of advanced protection controls. MKS Mass Spectrometry process systems have the most advanced protection algorithms in the market, but they do have manual overrides that could be inadvertently misused.

MKS Mass Spectrometry analyzers have been designed so that they can be easily cleaned and repaired in the field by the customer. Filaments can be quickly replaced with pre-aligned modules that do not require any special tools or jigs. The ion sources can be removed as one unit for cleaning or replacement in a matter of minutes. Even the channel electron multiplier can be replaced without the need for spot welding equipment. The following pages show the analyzer disassembly procedure.

This design benefit and flexibility will significantly reduce operating cost and increase uptime when compared to other RGA systems on the market. If high uptime is required or if the analyzers are used in an environment which would require constant source cleaning, then it is recommended that a spare ion source is used. This spare source can be exchanged with the contaminated source and the analyzer will be ready for operation again in approximately 15 minutes.

MKS Application Support and Customer Support Groups will provide complete training on any level for the residual gas analyzers. This includes complete training in preventative maintenance, routine repair, and normal operation and data collection. More advanced training in theory, operation and data interpretation is also available. The Application Support Group is also available to work with customers to develop process recipes and other methods to fully utilize the RGA capabilities and provide superior uptime for both the RGA and process system.

Filament Replacement:

Filament Replacement

Quick and easy using pre-aligned filaments assemblies.

The dual independent filaments on the MKS analyzers can be easily changed by removing the two barrel connectors and loosening the two holding screws. The mirror image filament plates can then be removed and replaced with a new set. The filaments are mounted and pre-aligned on the filament plate for easy handling. All MKS ion sources, except the UHV version, use the same filament assemblies to minimize required spare parts stock.

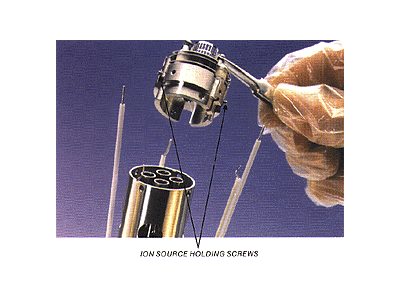

Ion Source Removal:

Ion Source Removal

Clean or exchange to remove contamination

The complete ion source can be removed in one module by disconnecting the filament leads, then, using the 1.5mm hex wrench supplied in the installation kit, the wires to the source and the source holding screws can be loosened. At this point the complete source can be removed and cleaned or replaced. The manual gives detailed instructions for source cleaning.

Mass Filter Cover:

Mass Filter Cover

Remove to access rod assembly.

The cover for the mass filter can be removed to access the filter for cleaning. Electrical connections to the rods have to be removed along with the screws at the base of the cover. The cover then slips up over the rod assembly. At this point cleaning of the rod assembly could be done. Check with MKS Customer Support Group for more details on mass filter cleaning.

WARNING!!

The mass filter assembly must not be disassembled at any time. Otherwise, expensive factory realignment may be required!

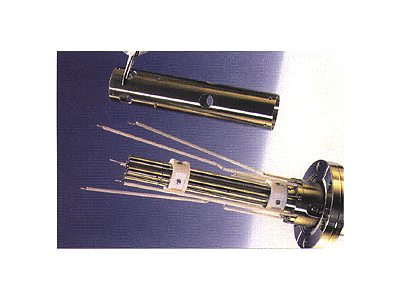

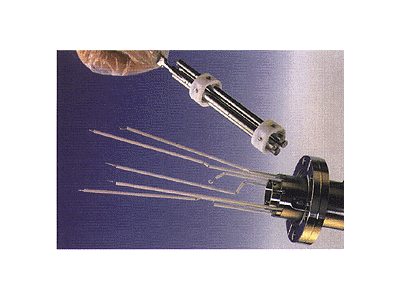

Multiplier Replacement:

Multiplier Replacement

Remove mass filter assembly to access multiplier

The complete mass filter assembly can be removed to access the channel electron multiplier. The multiplier assembly can then be replaced without the need for special tools or spot welding equipment. Call the MKS Customer Support Group at 408-750-0300 for more details on multiplier replacement.

Ultra-High Velocity

Ultra-High Velocity