Single-Crystal Diamond Wafers: Redefining Semiconductor Performance

Overview

As the demand for faster, more efficient, and sustainable electronics accelerates, the industry faces critical challenges regarding heat management and power density. Traditional materials like silicon (Si) and even silicon carbide (SiC) are approaching their limits. The next frontier in high-performance electronics is the single-crystal diamond wafer, a material with the potential to redefine performance benchmarks in power electronics, AI, and advanced computing.

The key enabler behind this breakthrough? Microwave Plasma Chemical Vapor Deposition (MPCVD).

Why Diamond? The Ultimate Semiconductor Material

Diamond offers exceptional properties that surpass conventional semiconductor materials:

- Unmatched Thermal Conductivity: With thermal conductivity up to 2200 W/m·K (significantly higher than copper or SiC), diamond drastically reduces cooling costs, enables higher power densities, and improves system reliability.

- Miniaturization Potential: Diamond-based devices are smaller and lighter, facilitating more compact and efficient designs for critical applications in EVs, data centers, AI systems, and aerospace.

- Sustainability & Efficiency: Lower energy losses in diamond-based devices translate to greener operations, helping meet stringent efficiency demands and compliance standards.

MPCVD: The Key to Electronic-Grade Diamond

Advanced Microwave Plasma Chemical Vapor Deposition (MPCVD) processes allow engineers to grow electronic-grade single-crystal diamond with precise, controlled doping. This unlocks revolutionary device architectures:

- GaN-on-Diamond HEMTs (High Electron Mobility Transistors)

- All-diamond power diodes and MOSFETs for ultra-high voltage applications

- Quantum and photonic devices leveraging diamond’s unique optical properties

- High-performance AI applications

Doping Techniques for Diamond Semiconductors

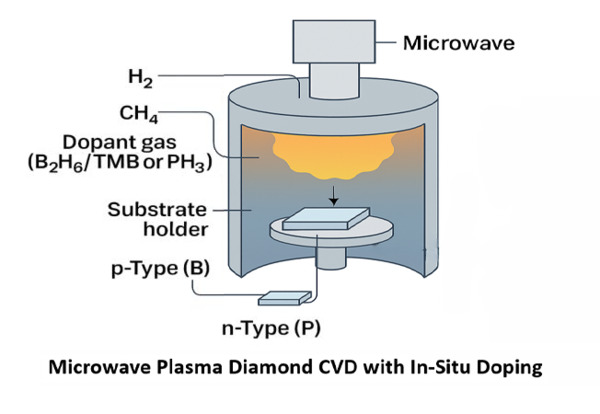

Achieving functional semiconductor devices requires controlled incorporation of dopants. MPCVD facilitates this through efficient in-situ doping during growth:

Microwave Plasma CVD In-Situ Doping:

- P-type Doping (Acceptor): Boron is added by introducing boron-containing gases (e.g., diborane, B₂H₆, or trimethylboron) into the methane/hydrogen plasma during CVD. Boron substitutes for carbon in the crystal lattice, creating acceptor levels. Achievable concentrations range from lightly doped (1014 cm-3) to heavily doped (>1020 cm-3 for p+ contacts).

- N-type Doping (Donor): This uses phosphorus (Ph2) or sometimes sulfur/oxygen during growth. Research is ongoing to improve the activation and stability of n-type dopants.

Post-CVD Growth Doping (Ion Implantation):

- Ion implantation is used for selective doping or forming junctions but requires high-energy ions and subsequent extreme-temperature annealing to repair lattice damage. Activation efficiency is typically low compared to in-situ methods.

Why MKS Microwave Systems Enhance this Process

MKS provides the crucial power and process control solutions that make high-quality, high-rate single-crystal diamond growth possible. The reliability and stability of the microwave source are fundamental to this process.

- Precise Power and Process Control: MKS generators offer highly stable and continuous adjustment of microwave power, preventing arcing or plasma instability that can damage delicate seed crystals and disrupt growth. This stability ensures a reliable and robust process window for growing high-quality diamond (Type IIa or better).

- Support for High Power Density Operation: High-quality diamond growth at high rates requires high power densities and high operating pressures (above 160 Torr). MKS systems are engineered to support these demanding conditions, enabling faster growth rates without sacrificing crystal quality.

- Optimized Plasma Uniformity: MKS components are designed to help maintain a stable and uniformly distributed plasma ball over large substrates. This uniform plasma is essential for consistent growth across the entire wafer, addressing a key challenge in scaling up diamond synthesis.

- Rugged Reliability & Scalability: Built for continuous operation in industrial settings, MKS microwave power generators are highly efficient and reliable. Their modular design facilitates scalability from R&D setups to large-area production, ensuring process consistency as operations expand.

- Integrated Solutions: MKS offers a broad suite of solutions, including pressure and flow measurement and control, gas delivery, and power generation. This integrated approach ensures every critical parameter of the advanced manufacturing process is precisely controlled, leading to improved performance and productivity.

MKS solutions enable and enhance Microwave Plasma Chemical Vapor Deposition (MPCVD).

Learn More:

- MKS offers compact industrial microwave generators and systems in 915MHz and 2450MHz that are adaptable to a wide range of applications. See our Microwave Generators and Systems here

- Contact an MKS Applications Specialist to discuss how MKS Microwave Systems can improve your process.

Ultra-High Velocity

Ultra-High Velocity