Microwave Technology: Powering the Green Industrial Transition

Overview

As global industries accelerate the shift toward sustainability and decarbonization, MKS is at the forefront, leveraging advanced microwave technology to drive energy efficiency and innovation across critical green domains.

The Microwave Advantage in Green Processing

MKS microwave generators deliver precise, energy-efficient power that enables volumetric heating, a fundamental shift from conventional surface heating methods. This core capability leads directly to measurable environmental and economic benefits:

- Faster Processing Times: Energy is delivered simultaneously throughout the material, drastically cutting thermal cycling time.

- Significant Energy Savings: Higher energy coupling efficiency reduces the overall power consumption per unit of processed material.

- Lower Emissions and Waste: Optimized processes require fewer chemical inputs and reduce the generation of by-products.

- Improved Material Performance: Rapid, uniform heating can lead to finer grain structures and enhanced material properties.

Enabling Sustainable Materials & Manufacturing

MKS microwave solutions are integral to high-impact applications that support the Circular Economy and Green Chemistry:

- Green Materials Processing: Delivering precise, energy-efficient heating for demanding steps like sintering, coating, and critical materials recycling, directly supporting circular manufacturing and reduced CO2 emissions.

- Battery & Critical Materials: Implementing microwave systems to efficiently recycle valuable metals from spent Electric Vehicle (EV) batteries and support next-generation battery component production.

- Nanomaterials & Green Chemistry: Facilitating eco-friendly synthesis of complex materials, including using plant-based (biomass) precursors, reducing reliance on harsh solvents.

- Waste-to-Value Conversion: Transforming industrial and municipal waste (e.g., plastics, biomass) into high-value reusable compounds like activated carbon and syngas.

Turquoise Hydrogen & Decarbonization

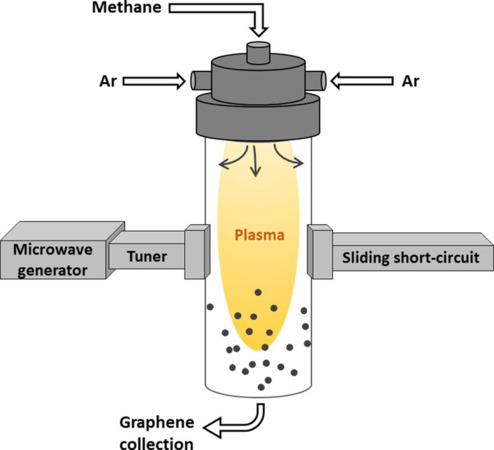

MKS microwave plasma systems are a game-changer in the transition to low-carbon energy by enabling Turquoise Hydrogen production— a CO2-free method for hydrogen generation.

Process: Our microwave generator solutions power methane pyrolysis, which splits methane (CH4) into:

- Clean Hydrogen (H2), a zero-emission fuel source.

- High-Value Solid Carbon (e.g., carbon black, graphene), a marketable by-product.

Advantages: This is an electrode-free and catalyst-free process that is highly scalable and supports decentralized, point-of-use hydrogen infrastructure, avoiding the high cost and environmental concerns of CO2 capture and storage.

MKS technology supports zero-waste workflows and hydrogen-ready industrial systems, underscoring our commitment to industrial innovation aligned with planetary sustainability goals.

- MKS offers compact industrial microwave generators and systems in 915MHz and 2450MHz that are adaptable to a wide range of applications. See our Microwave Generators and Systems here

- Contact an MKS Applications Specialist to discuss how MKS Microwave Systems can improve your process.

Ultra-High Velocity

Ultra-High Velocity