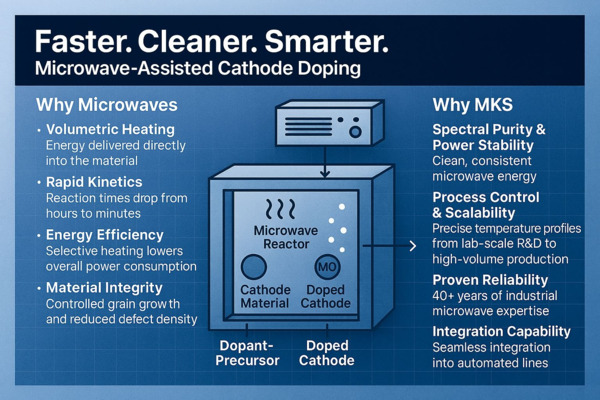

Microwave-Assisted Cathode Doping: Faster. Cleaner. Smarter.

Overview

For engineers developing advanced energy storage systems, cathode doping is a critical process step required to achieve higher voltage stability, extended cycle life, and enhanced safety. Traditional thermal processes often fall short, characterized by slow kinetics, high energy consumption, and non-uniform dopant distribution.

Microwave-assisted doping provides a high-efficiency alternative, transforming cathode synthesis from a bottleneck into a strategic advantage.

The Microwave Advantage: Precision Volumetric Processing

Unlike conventional furnace heating, which relies on slow thermal conduction from the surface inward, microwave energy interacts directly with the material at a molecular level.

- Volumetric Heating: Energy is delivered uniformly throughout the material volume. This eliminates thermal gradients, ensuring consistent dopant diffusion across the entire cathode structure.

- Accelerated Reaction Kinetics: Microwave-to-matter interaction reduces reaction times from hours to mere minutes. This drastically shortens manufacturing cycle times and accelerates R&D iterations.

- Enhanced Energy Efficiency: Selective heating targets the material rather than the furnace environment, significantly lowering power consumption and reducing the carbon footprint of the production line.

- Superior Material Integrity: Precise control over energy delivery allows for controlled grain growth and reduced defect density, resulting in optimized electrochemical performance and structural stability.

Why MKS Microwave Technology?

MKS provides the industrial-grade microwave subsystems required to move cathode doping from the lab to high-volume manufacturing:

- Spectral Purity & Power Stability

Reproducibility is paramount in battery chemistry. MKS delivers clean, consistent microwave energy that ensures every batch of doped cathode material meets exact specifications. - Process Control & Scalability

Our advanced tuning and monitoring systems allow engineers to maintain precise temperature profiles. MKS technology scales seamlessly from lab-scale R&D units to high-throughput industrial production lines. - Proven Industrial Reliability

With over 40 years of expertise in industrial microwave applications, MKS provides a robust hardware platform backed by a global support infrastructure. We understand the rigors of 24/7 manufacturing environments. - Seamless Integration

Designed for the modern "Gigafactory," MKS microwave systems are built for integration into fully automated production lines, enabling the next generation of battery manufacturing.

Engineering the Future of Energy Storage

Microwave-assisted doping is more than an incremental improvement—it is a fundamental enabler for high-performance battery chemistry and competitive manufacturing.

Optimize your cathode synthesis with MKS.

To explore technical specifications or discuss your process requirements, visit the MKS Microwave Products page or contact our global engineering team.

Ultra-High Velocity

Ultra-High Velocity