Accelerating Superconducting Material Synthesis with Microwaves

Overview

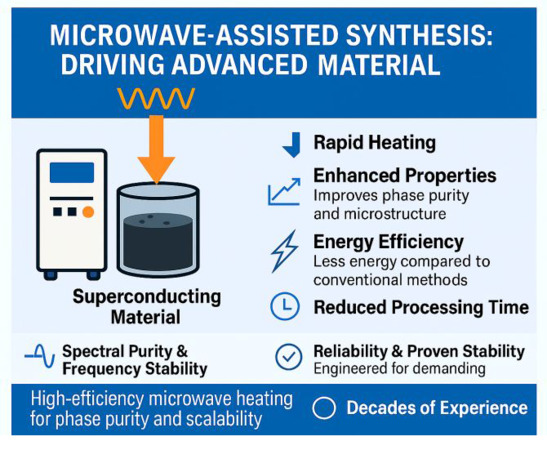

Microwave-assisted synthesis is transforming superconducting material processing by enabling volumetric energy transfer and non-equilibrium reaction pathways that conventional technologies cannot achieve.

This results in faster phase formation, improved grain connectivity, and enhanced critical current density, key for next-generation superconductors.

Key Advantages over Conventional Methods

- Volumetric Energy Transfer: Conventional heating transfers heat from the outside of the material inward (through the vessel walls), creating thermal gradients and hot spots, leading to non-uniform temperature distribution and localized overheating. Microwave heating, however, uses electromagnetic radiation to directly interact with polar molecules and ions throughout the entire volume of the material simultaneously, generating internal heat uniformly.

- Non-Equilibrium Reaction Pathways: The rapid and efficient energy transfer allows reactions to reach high temperatures in minutes (or even seconds) rather than hours or days. This rapid heating rate creates conditions where the energy transfer is faster than the molecular relaxation, resulting in non-equilibrium conditions which can stabilize phases with unique electronic or structural properties. That can favor the formation of novel or metastable phases of materials that might not form under slower, conventional heating.

- Faster Phase Formation: The ability to rapidly achieve and maintain high, uniform temperatures significantly accelerates the kinetics of the synthesis process. This speed is crucial for complex materials like high-temperature superconductors (e.g., REBCO materials).

- Improved Grain Connectivity: The homogeneous heating and resulting uniform nucleation and growth conditions lead to materials with more consistent microstructures and a more uniform size distribution of particles. This improved control over the grain formation process directly translates to better connectivity between the grains in the final solid material.

- Enhanced Critical Current Density: Better grain connectivity and control over the microstructure are essential for high-performance superconductors. Improved connectivity allows for more efficient supercurrent flow across the material, enhancing the critical current density.

At MKS, we offer dedicated microwave generators at 915 MHz and 2.45 GHz, giving researchers and manufacturers the flexibility to optimize penetration depth, coupling efficiency, and material characteristics.

MKS Microwave Technology Stands Out:

- Spectral Purity & Frequency Stability: Clean, stable signal for precise electromagnetic coupling, enabling uniform heating and reproducible material properties.

- Reliability & Proven Stability: Engineered for continuous operation in the most demanding technology environments.

- Precise Power Control: Uniform energy distribution and minimized thermal gradients for consistent results.

- Scalable Architecture: From benchtop experiments to full-scale reactors, maintaining process fidelity across scales.

- Decades of Experience: Trusted by the world’s most advanced technology businesses for high-performance solutions.

Learn More:

Microwave technology is about enabling controlled microstructure evolution and phase purity optimization for superconductors and other advanced materials, and MKS can accelerate your innovation.

- MKS offers compact industrial microwave generators and systems in 915MHz and 2450MHz that are adaptable to a wide range of applications. See our Microwave Generators and Systems here

- Contact an MKS Applications Specialist to discuss how MKS Microwave Systems can improve your process.

Ultra-High Velocity

Ultra-High Velocity