Microwave Technology: The Strategic Enabler for Next-Generation AI Semiconductor Manufacturing

Overview

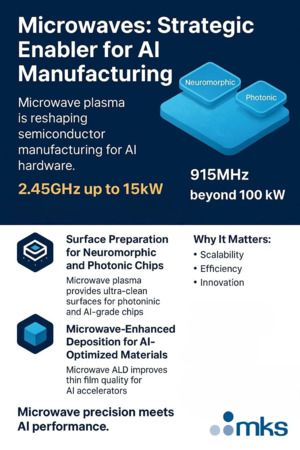

The rapid scaling of AI systems, from edge inference to hyperscale training clusters, necessitates a paradigm shift in semiconductor manufacturing towards hardware with unparalleled performance and minimal defects. Microwave technology is increasingly crucial in meeting these stringent demands, facilitating ultra-clean surfaces, high-precision etching, and advanced packaging techniques for complex neuromorphic and photonic chips.

Core Applications in AI Semiconductor Fabrication

High-Purity Surface Preparation for Neuromorphic and Photonic Chips

Microwave plasma provides contamination-free, uniform surface treatments that are essential for high-yield manufacturing of advanced integrated circuits. The electrode-free design is a key advantage, ensuring high-purity processing without the risk of metal ion contamination, which is vital for AI-grade semiconductors.

Advanced Packaging for High-Density AI Accelerators

Innovative microwave-assisted bonding and cleaning processes directly support the integration of sensitive low-k dielectrics and fused silica substrates. This approach significantly enhances signal integrity and improves thermal management within high-density AI chips.

Microwave-Enhanced Deposition for AI-Optimized Materials

Microwave-enhanced Atomic Layer Deposition (MW-ALD) improves thin film quality by effectively removing impurities and repairing defects in situ. This enables the low-temperature, high-purity deposition required for next-generation AI accelerators.

The MKS Advantage: Efficiency and Scalability

At MKS, our advanced power microwave generators are engineered to drive this innovation. We provide robust solutions, including 2.45GHz generators up to 15kW and 915MHz systems exceeding 100kW, enabling critical processes across the fabrication lifecycle.

Implementing MKS microwave solutions offers distinct advantages for semiconductor engineers and production managers:

- Scalability: MKS microwave systems provide consistent process fidelity, scaling seamlessly from R&D lab environments to high-volume production fabs.

- Energy Efficiency: Targeted energy delivery minimizes process waste and contributes to lower overall operating costs.

- Innovation Velocity: Our technology accelerates materials science and device development cycles, enabling faster iteration and time-to-market.

Microwave precision is the critical link to achieving AI performance. The power and control provided by MKS technology unlock the future of intelligent computing systems.

- MKS offers compact industrial microwave generators and systems in 915MHz and 2450MHz that are adaptable to a wide range of applications. See our Microwave Generators and Systems here

- Contact an MKS Applications Specialist to discuss how MKS Microwave Systems can improve your process.

Ultra-High Velocity

Ultra-High Velocity