MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

T2BA EtherCAT®, RS232, RS485, DeviceNet®, and Analog/TTL I/O Exhaust Throttle Valves with Integrated Controller

Overview

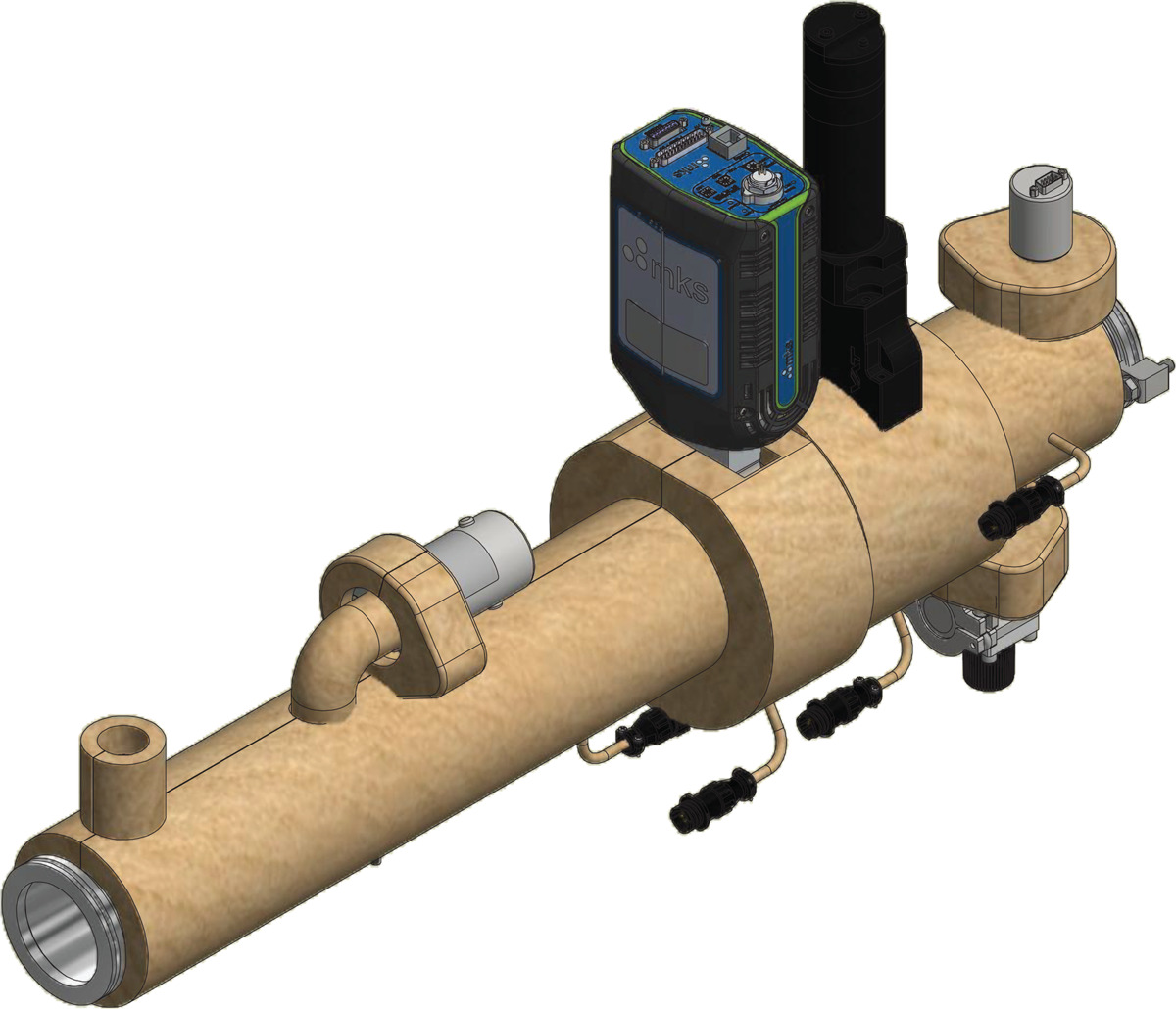

T2BA EtherCAT®, RS232, RS485, DeviceNet®, Analog/TTL Exhaust Throttle Valves with Integrated Controller are specifically designed for applications where a simple, yet advanced, pressure control system is desired. The T2BA integrates all control, communication, and driver circuits within a throttle valve assembly, eliminating the need for mounting a separate pressure control electronics module. The unique model-based control algorithm and high-speed operation drives the system to set point quickly with minimum overshoot, and ensures repeatable process recipes without operator involvement.

- On-board LCD touchscreen display of pressure and position

- Programmable for pressure or position control

- Encoder-based actual position verification

- Heatable valve body (105°C standard, 150°C and 200°C optional)

Products

Configuration Options

The following options are available for T2B Exhaust Throttle Valves

Ordering Code Example: T2BA01K220203V400034

| Configuration Option | Option Code |

|---|---|

T2B Downstream Pressure Controller |

T2BA |

Valve Bore/Flange Size |

|

| 20 mm/KF25 | 19K |

| 1 in./NW40 ISO-KF | 01K |

| 2 in./NW50 ISO-KF | 02K |

| 60 mm/NW63 | 60N |

| 3 in./NW80 | 03N |

| 4 in./NW100 | 04N |

| 6 in./NW160 | 06N |

Flapper Type |

|

| Non-Sealing | 2 |

| Low-Conductance F-seal | 3 |

| Low-Conductance Q-seal | 4 |

Drive Type |

|

| Direct Drive, NEMA 23-2, 8 in-lb | 2 |

| Direct Drive, NEMA 24-2, 25 in-lb | 4 |

| Geared Drive, NEMA 17-1 20:1, 40 in-lb | 3 |

Nominal Radial Gap (NRG), Flapper/Body |

|

| 0.000 in. NRG (F-seal or Q-seal) | 000 |

| 0.002 in. (standard for 1 or 2 in. and 60mm) | 020 |

| 0.003 in. (standard for 3 or 4 in.) | 030 |

| 0.005 in. (standard for 6 in.) | 050 |

Heatability |

|

| Up to 105°C, without fan (for drive type selection 2 only) | 3 |

| Up to 105°C, with fan (for drive type selections 4 and 3) | 1 |

| Up to 150°C (all drive types) | 2 |

| Up to 200°C (all drive types) | 4 |

Seal Materials (Valve Shaft) |

|

| Viton | V |

| Chemraz E38 | C |

| Chemraz 592 | D |

| Chemraz 515 | W |

| Kalrez 4079 | L |

| Kalrez 8085 | K |

| Kalrez 9100 | M |

| Kalrez 9500 | N |

Communications |

|

| Analog/TTL, w/LCD | 0 |

| RS232, analog pressure input, w/LCD | 2 |

| EtherCAT, no analog w/LCD | 4 |

| RS485,analog pressure input, w/LCD | 5 |

| DeviceNet, w/out analog outputs | D |

Pressure Sensor Power Supply |

|

| No Power | 0 |

| ±15 VDC @ 650 mA total (only available RS232, RS485, DeviceNet and Analog/TTL types) | 1 |

Reserved |

|

| Reserved | 00 |

Firmware |

|

| MKS will ship the current firmware revision | 34 |

Specifications

-

TypeT2BA Exhaust Throttle Valve

-

Accuracy0.25% of set point, or 5mV (whichever is greater)

-

Control Range0.0001%-100% Full Scale (with Dual Transducer Input)

-

Flapper TypesNon-sealing and low-conductance soft-sealing

-

Operating TemperatureMotor and Electronics: 15 - 50°C

Valve Body: 105°C standard, 150 & 200°C optional

Storage Temperature: -20 - 80°C -

Exposed MaterialsNon-sealing Types: 316 SST, Tefzel

Low closed-conductance soft-sealing Types: 316 SST, Tefzel, PTFE

Shaft Seal Material: Viton, Kalrez®, Chemraz®, and others -

Shaft Seal MaterialViton shaft seals are available for valve body temperatures that will not exceed 105°C and process gases compatible with Viton. For valve body heating as high as 150°C and/or process gas compatibility, various Kalrez and Chemraz compounds are also offered.

-

External Leak Rate1 e-9 atm cc/sec

-

Power Requirements24 VDC @ <100 W max.

4A supply capacity recommended

-

Valve Bore and Flange SizeKF40, KF50, NW63, NW80 and NW100

Additional sizes available -

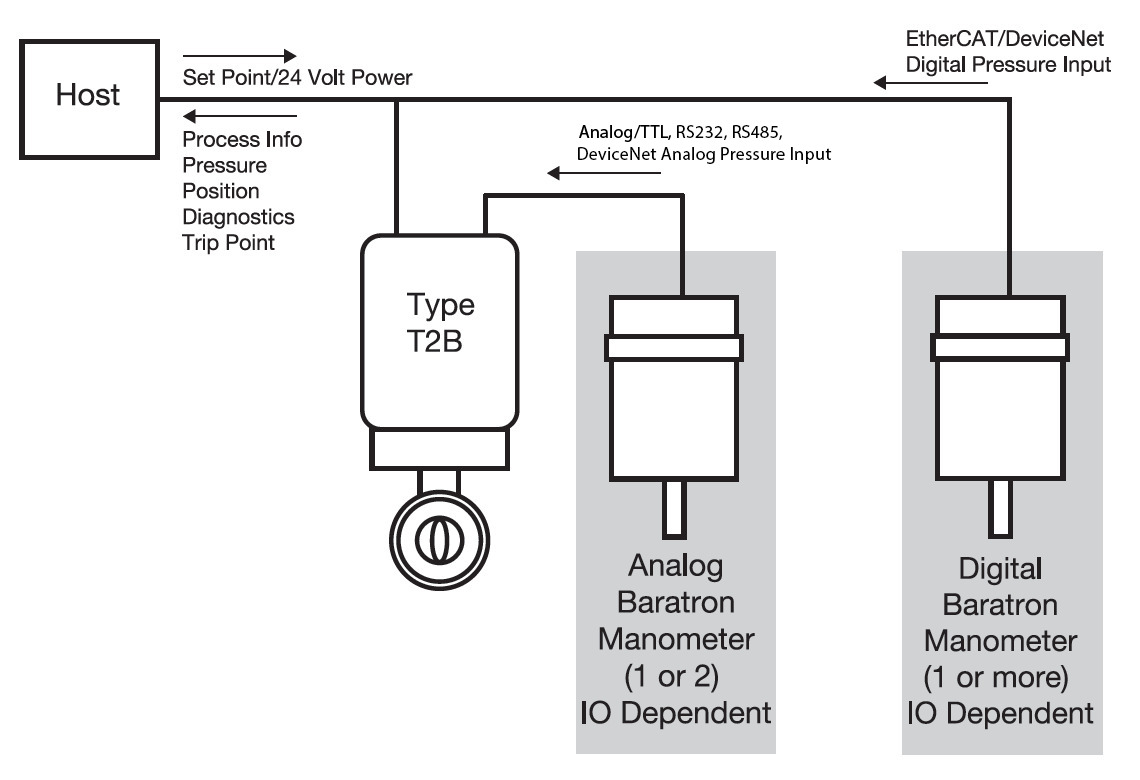

Pressure Sensor PowerEtherCAT pressure sensors exchange data to the master and the data is available (typically ~ 1 ms refresh) as standard PDO data to the T2BA

Communication interfaces other than EtherCAT support up to 2 analog capacitance manometers.

An optional integrated power supply can supply up to 650 mA of ±15 VDC of power for one or two manometers. -

Nominal Radial GapStandard clearances are appropriate for most applications.

Consult MKS for applications with high internal heating. -

HeatabilityAll T2BA valves allow the valve body to be heated to 105°C standard or optionally 150°C or 200°C.

T2BA valve bodies may be heated up to 200°C with the heatability option and appropriate selection of shaft seal compound. -

Drive8 in-lb Direct Drive

25 in-lb Direct Drive

40 in-lb High Torque -

CommunicationsEtherCAT ETG. 5003.1 Common Device Profile; ETG.5003.2030 Process Control Valve

RS232 full duplex

RS485 half duplex

DeviceNet

Analog/TTL -

Pressure InputT2BA with an EtherCAT interface do not include nor need analog connections to the process tool pressure sensors.

EtherCAT pressure sensors exchange data to the master and the data is available (typically ~ 1 ms refresh) as standard PDO data to the T2BA enabling fast, noise-free, and precise closed-loop pressure control.

Communication interfaces other than EtherCAT support up to two analog capacitance manometers.

An optional integrated power supply can supply up to 650mA of ±15 VDC of power for one or two manometers. Not available with EtherCAT -

ComplianceCE

Features

T2BA Comunications Options

| Digital I/O | DeviceNet™ | RS232 | RS485 | EtherCAT® | Analog/TTL |

|---|---|---|---|---|---|

| Input Power Required | +24 VDC, 100W Max. | +24 VDC, 100W Max. | +24 VDC, 100W Max. | +24 VDC, 100W Max. | +24 VDC, 100W Max. |

| Connector | 5 pin micro connector (comms) 25 pin Type D male(power, DIO) 15 pin Type D female (sensor power and signal) RJ-45 (Diagnostics) |

25 pin Type D male (power, DIO and comm.) 15 pin Type D female (sensor power and signal) RJ-45 (Diagnostics) |

25 pin Type D male (power, DIO and comm.) 15 pin Type D female (sensor power and signal) RJ-45 (Diagnostics) |

25 pin Type D male (power and DIO) 2 x RJ-45 (Ethercat comm. In/Out) 1 x RJ-45 (Diagnostics) |

25 pin Type D male (power, AIO and DIO) 15 pin Type D female (sensor power and signal) RJ-45 (Diagnostics) |

| Data Rate Switch/Selection | 4 positions: 125, 250, 500K (Default) (programmable over network) |

No switch Set data rate via RS232 | No switch Set data rate via RS485 | No switch Managed via Host |

No switch Set data rate via RS232 |

| Comm. Rate(s) | 125 Kbps; 250 Kbps; 500 Kbps | 9.6 Kbps; 19.2 Kbps; 38.4 Kbps; 57.6 Kbps; 115.2 Kbps | 9.6 Kbps; 19.2 Kbps; 38.4 Kbps; 57.6 Kbps; 115.2 Kbps | Managed via Host | 9.6 Kbps; 19.2 Kbps; 38.4 Kbps; 57.6 Kbps; 115.2 Kbps |

| MAC ID Switches/Addresses | 2 switches, 10 positions; 0,0 to 6,3 | n/a | Set address over RS485 Addresses 0 to 999 |

Set on LCD 3 characters 16 values each |

N/A |

| Network Size | Up to 64 nodes | n/a | Up to 32 nodes | Up to 4095 nodes | N/A |

| Visual Indicators | LED Network (green/red) LED Module (green/red) |

LED Comm (green) LED Error (red) |

LED Comm (green) LED Error (red) |

LED Power (green) LED Run (green) LED Error (red) LED Comm (green) |

LED Comm (green) LED Error (red) |

| Compliance | CE | CE | CE | CE | CE |

High-speed Stepper Motor

The T2BA utilizes a direct drive high-speed stepper motor. The valve driver provides high resolution pressure control. The optional, high torque direct drive motor provides extended uptime and reduces preventative maintenance cycles — a great advantage in demanding processes where just one hour of downtime can cost thousands of dollars. The T2BA is also available in geared versions, providing maximum torque and enabling long-term operation in harsh environments.

T2BA Pressure Control System

T2BA Exhaust Throttle Valves can operate in two modes: flapper positioning or pressure control, either of which can be user-activated through the I/O interface. All of the adjustable setup parameters, run time operation, and diagnostics information is available through the communications interface. EtherCAT T2BA is only compatible with EtherCAT manometers.

The downstream pressure control technique provides wide dynamic range, works with all types of pumps, provides fast response, and is tolerant to most effluent gases. The "intelligent instrument" concept results in valuable system space savings, improved noise immunity, and easy access to time-critical process and calibration information as well as on-board diagnostic functions.

Resources

Literature

- T2BA Exhaust Throttle Valve (1.5 MB, PDF)

Drawings & CADs

- T2B Throttle Valve Dimensional Drawing (4.3 MB, PDF)

Manuals

- T2BA EtherCAT Manual (1065875-001) (3.2 MB, PDF)

- T2BA RS232 Manual (20022906-001) (2.6 MB, PDF)

- T2BA Butterfly Valve with Analog/TTL Interface Instruction Manual (20089532-001) (5.8 MB, PDF)

- T2BA Butterfly Valve with RS485 Interface Instruction Manual (20096854-001) (4.8 MB, PDF)

- T2BA Butterfly Valve with DeviceNet™ Interface Instruction Manual (20047526-001) (4.5 MB, PDF)

- T2BA Throttle Valve with DeviceNet™ Interface Supplemental Manual (20047527-001) (1.3 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity