MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

IDA™ In Situ Diagnostic Access Isolation Valves

Overview

IDA™ In Situ Diagnostic Access Isolation Valves increase the accuracy of, and reduces the time needed for, gauge or capacitance manometer zeroing and calibration during preventative maintenance intervals. They also provide a process chamber access port that enables additional functions, such as system leak checks and diagnostics. Accurate, absolute pressure measurement in-situ with the IDA valve ensures uniformity and repeatability on a system and a system-to-system basis. Process system uptime and productivity are also enhanced, and costs are reduced.

- NW16 or VCR

- Dual-valve design provides safe and controlled reference port access

- Multi-function capability with direct access to process chamber for leak checks

Products

| Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|

| IDA-LEV Diagnostic Access Valve, In Situ, Left-handed, Viton Seal, Viton Nosepiece | $992 |

|

||||

|

Diagnostic Access Valve, In Situ, Left-handed, Chemraz Seal, Chemraz Nosepiece

$1,248

|

IDA-LEZ Diagnostic Access Valve, In Situ, Left-handed, Chemraz Seal, Chemraz Nosepiece | $1,248 |

|

|||

|

Diagnostic Access Valve, In Situ, Left-handed, Copper Seal, Viton Nosepiece

$1,108

|

IDA-LMV Diagnostic Access Valve, In Situ, Left-handed, Copper Seal, Viton Nosepiece | $1,108 |

|

|||

|

Diagnostic Access Valve, In Situ, Left-handed, Copper Seal, Chemraz Nosepiece

$1,278

|

IDA-LMZ Diagnostic Access Valve, In Situ, Left-handed, Copper Seal, Chemraz Nosepiece | $1,278 |

|

|||

| IDA-REV Diagnostic Access Valve, In Situ, Right-handed, Viton Seal, Viton Nosepiece | $992 |

|

||||

|

Diagnostic Access Valve, In Situ, Right-handed, Chemraz Seal, Chemraz Nosepiece

$1,248

|

IDA-REZ Diagnostic Access Valve, In Situ, Right-handed, Chemraz Seal, Chemraz Nosepiece | $1,248 |

|

|||

| IDA-RMV Diagnostic Access Valve, In Situ, Right-handed, Copper Seal, Viton Nosepiece |

|

|||||

| IDA-RMZ Diagnostic Access Valve, In Situ, Right-handed, Copper Seal, Chemraz Nosepiece |

|

Specifications

-

TypeDiagnostic Access Valve

-

SealCopper, Viton®, or Chemraz®

-

Nose SealViton® or Chemraz®

-

Control Port Options1/8 in. tube

-

Access PortKF-NW16

-

Gauge Port8 VCR® male

-

Chamber Port8 VCR® female

Features

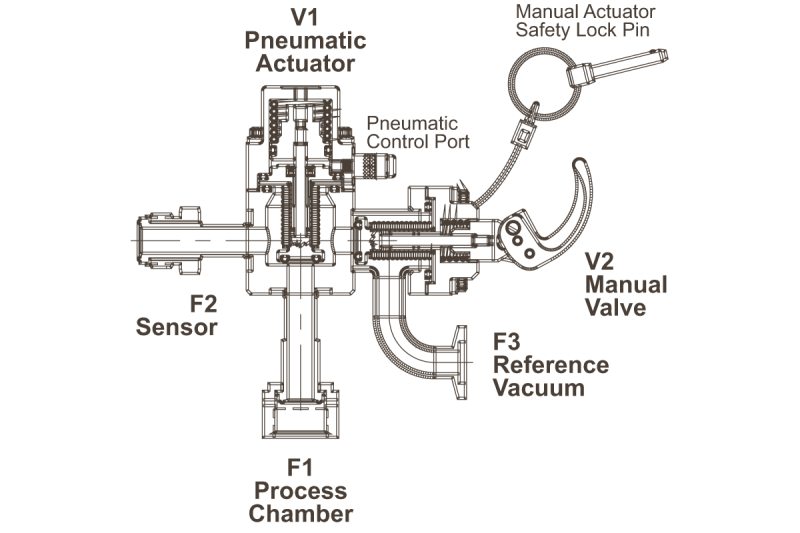

Diagnostics Access Valve Design

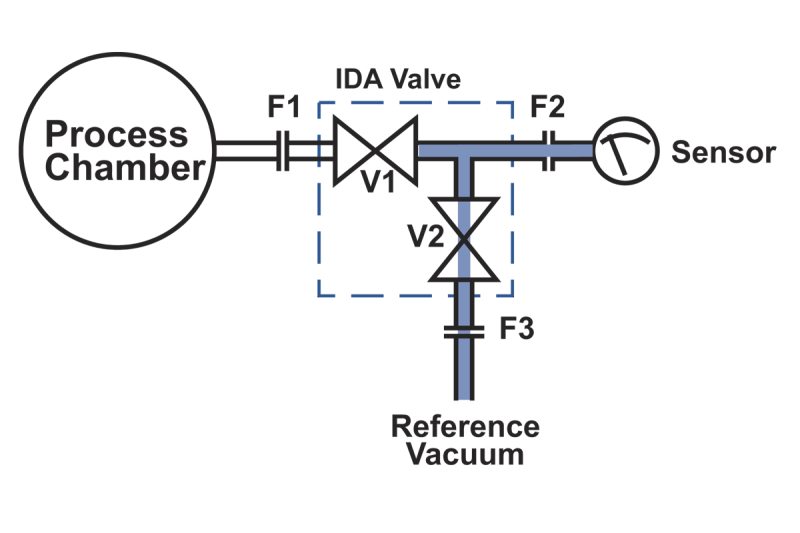

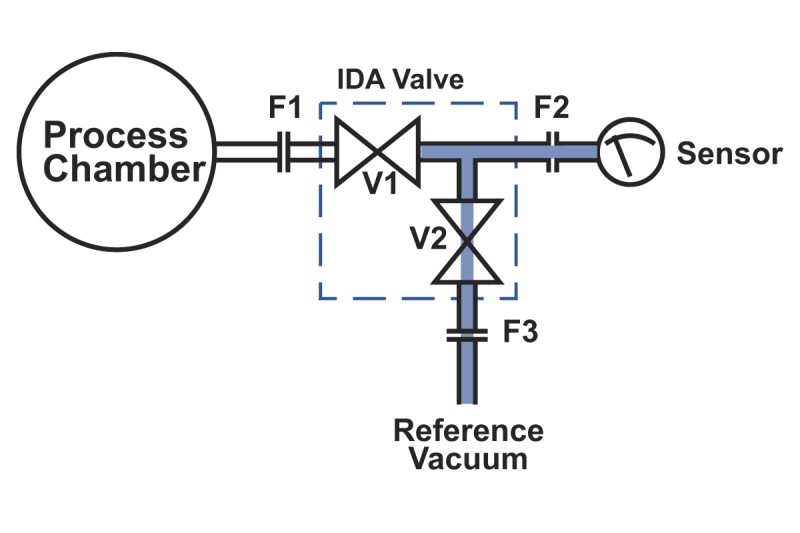

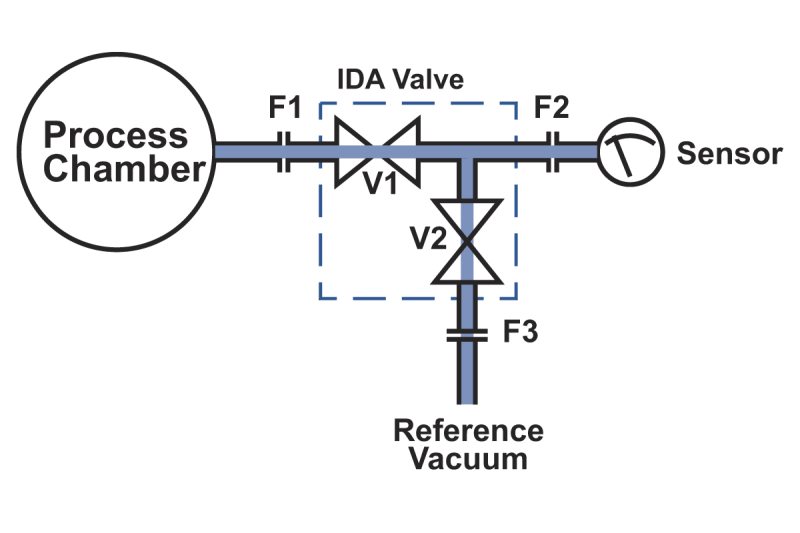

The IDA Valve joins a pneumatically actuated primary valve with a manually actuated secondary valve, both based on the MKS Cv Valve design. Functionally, it resembles a pair of two-way valves joined by a tee where V1 is the primary valve and V2 is the secondary valve. This configuration allows for two standard, mirror-image port orientations for your system: a left-oriented body and a rightoriented body.

Applications

The IDA™ Valve (In-situ Diagnostics Access Valve) is a multi-purpose, multi-port, dual valve designed to replace the standard isolation valve used in capacitance manometer and other types of gauge isolation in the semiconductor industry. It is an extension of the proven family of compact, high conductance modular MKS Cv™ Valves.

Gauge Diagnostics and Calibration Verification

In the figure, the gauge is isolated from the process chamber (Vl closed). Valve V2 is then opened, creating a short, high conductance access path for in-situ gauge zeroing or calibration. This can be done via a high quality leak detector/high vacuum system or a complete transportable calibration system.

Left or Right Orientations

On the x-y-z axis to the bottom left, a right-oriented valve body is shown as an example. Ports F1, F2, and F3 (process chamber, gauge, and reference/access ports, respectively) correspond to the axes as follows:

- A right-oriented valve body has its three vacuum ports, F1, F2, and F3, aligned with the +x, +y, and +z axes, respectively.

- A left-oriented valve body has its three vacuum ports, F1, F2, and F3, aligned with the +x, -y, and +z axes, respectively.

Accessories

Resources

Literature

- IDA In-Situ Diagnostics Access Valve (516.1 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity