MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

DA03B Heated (150 - 200°C) 1 - 1000 Torr, Absolute Baratron® Capacitance Manometer with EtherCAT®

Overview

The DA03B Baratron® Capacitance Manometer improves process capability by reducing output drift. Operating at sensor temperatures up to 200°C, the DA03B’s high temperature operation minimizes the deposition of process byproducts within the sensor. High temperature operation combined with a large sensor reduces sensor process contamination effects resulting in increased sensitivity and zero process related drift. The DA03B leverages the same proven digital architecture of the industry-standard DA02A, making it well suited for advanced applications such as Chemical Vapor Deposition (CVD), Atomic Layer Deposition (ALD), semiconductor processes, and lyophilization.

- Long-term performance in ALD, CVD, Lyophilization, and other advanced manufacturing processes

- Minimizes the deposition of byproducts

- Provides fail-safe over-temperature protection

- All-Inconel larger sensor for superior sensitivity, corrosion resistance, and long-term stability

Products

Configuration Options

The following options are available for DA03B Baratron® Heated Capacitance Manometers

Ordering Code Example: DA03B11TCES36BAA0000

| Configuration Option | Option Code |

|---|---|

Model |

|

| DA03B Absolute Manometer | DA03B |

Ranges (Torr) |

|

| 1 | 01 |

| 2 | 02 |

| 3 | 03 |

| 5 | 05 |

| 10 | 11 |

| 20 | 21 |

| 100 | 12 |

| 1000 | 13 |

Units of Measurement (as shown on calibration sheet) |

|

| Torr | T |

| mbar | M |

| kPa | K |

Fittings |

|

| 0.5 in. OD tube | BA |

| 8 VCR female | CE |

| 8 VCR male | CF |

| NW16-KF | GA |

| NW25-KF | GC |

| Mini-CF | HA |

| 1.5 in. TriClover1 | KA |

| 2.0 in. TriClover1 | KB |

Sensor Type |

|

| Standard | S |

| Deposition/Fluorine Friendly (1, 2, 10, 100, 1000 Torr) | L |

Input/Output Voltages |

|

| ±15 VDC | 2 |

| +24 VDC | 3 |

Sensor Temperature |

|

| 200°C | 2 |

| 160°C | 6 |

| 150°C | 5 |

Electrical Connector2 |

|

| 15-pin D with Screw Locks | B |

| 15-pin D with Slide Lock Posts | P |

Integral Relays3 |

|

| No Relays | 00 |

| Trip Point A Above Set Point, Trip Point B Above Set Point | AA |

| Trip Point A Above Set Point, Trip Point B Below Set Point | AB |

| Trip Point A Below Set Point, Trip Point B Below Set Point | BB |

| Trip Point A Below Set Point, Trip Point B Above Set Point | BA |

Reserved |

|

| Reserved For Future Use | 0 |

Calibration Orientation |

|

| Ranges 1 Torr and above (not required) | 0 |

Accuracy |

|

| Standard | 0 |

Other Options |

|

| None | 0 |

Notes:

1 Products with TriClover fittings have Type 316L stainless steel fittings.

2 For CE compliance, the mating electrical connector must be properly grounded.

3 Units with trip points have default set points of 50% of Full Scale, a default hysteresis of 0, and actuation direction based on the part number code. The settings are user adjustable through EtherCAT.

* Custom part numbers can be requested for copy exact applications.

** Standard part numbers will ship with the latest firmware at the date of manufacture. A custom part number should be requested for locked firmware/EtherCAT ESI file.

Specifications

-

TypePressure Transducer

-

Sensor TypeCapacitance Manometer

-

Measurement TypeAbsolute

-

Full Scale Range1, 2, 3, 5, 10, 20, 100, 1000 Torr

-

Accuracy±0.25% of Reading

-

Fitting TypeStandard:

0.5 in. (12 mm) OD tube

Optional:

Swagelok® 8 VCR® female, 8 VCR male, NW16-KF, NW25-KF, Mini-CF, 1.5 in. TriClover, 2 in. TriClover -

Analog OutputAnalog 0-10 VDC into >10kW load, EtherCAT

-

Trip RelaysStandard:

Two (2) internal solid state relays provided for heater "at temperature" status and heater failure. Relay capacity of 1 amp at 30 VDC.

Optional:

Two (2) internally mounted process pressure trip relays, solid state, independently adjustable by customer at atmospheric pressure from 0.5% to 100% of Full Scale range. Relay capacity of 1 amp @ 30 VDC. -

Resolution0.001% of Full Scale

-

Zero Temperature Coefficient150°C/160°C:

±0.004% Full Scale/°C for >1 Torr

±0.008% Full Scale/°C for 1 Torr range

200°C:

±0.008% Full Scale/°C for >1 Torr

±0.016% Full Scale/°C for 1 Torr range

-

Span Temperature Coefficient±0.02% Reading/°C

-

Response TimeAnalog/Digital:

35 ms (nominal) influenced by pressure range, step size, and digital pressure filter settings

EtherCAT:

Refresh Rate = 3.3 ms -

Warm-up Time2.5 hours typical

-

Internal Volume6.3 cm3 typical. Contact MKS for volumes with specific flanges.

-

Operating Temperature15 - 50°C

-

Overpressure Limit45 psia

-

Materials Exposed to Process GasesInconel® and Incoloy® nickel alloys (some fitting options are 300 Series Stainless)

-

Power Requirements±15 VDC @ 1.6A or +24 VDC @ 1.3A at start up (factory set)

-

Ambient Airflow Requirements150/160°C Models:

50 ft/min for ambient temperatures of 40 - 50°C

200°C Models:

150 ft/min for ambient temperatures of 40 - 50°C -

ComplianceCE, UL1577 (Trip Relays only)

Features

DA03B Details

The DA03B is completely self-contained and is available in either +24 VDC or ±15 VDC input power configurations. Its Inconel® sensor is resistant to corrosion, and its overpressure rating of 45 psia ensures good repeatability and stability regardless of the system operating conditions. Optional sensors and deposition traps are available for enhanced zero drift capabilities. The high-performance digital electronics of the DA03B also includes fail-safe over-temperature protection and LED status lights to indicate the operating state. Solid state relay outputs provide indication of sensor at temperature and heater failure. Additional options include an internally-mounted set of two (2) UL recognized solid state trip relays provided for pressure trip points for control of external equipment or components. The pressure trip relays may be set by the user over the EtherCAT bus at atmospheric pressure, eliminating the need for vacuum pumps during set point adjustment.

DA03B Key Features

- Sensor operating temperature of 150°C to 200°C (factory set)

- High 45 psia overpressure rating for improved stability and repeatability

- Optional internally-mounted, user programmable solid state process relays for external control

- Insensitive to gas composition

- EtherCAT interface and analog outputs

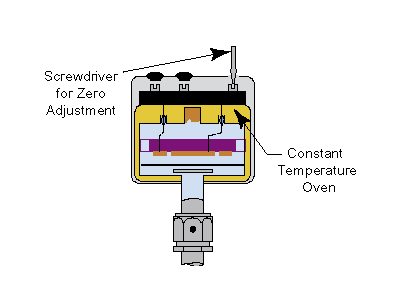

Internally Heated to 150, 160, or 200°C

These capacitance manometers are temperature controlled to 150, 160, or 200 degrees C for improved accuracy. Unheated sensors are exposed to ambient temperature variations which can degrade the sensor accuracy. These devices have the sensor enclosed in a volume that is maintained at a constant temperature above ambient. This solution improves the manometer’s accuracy and repeatability and lowers instrument drift by reducing or eliminating process contamination within the manometer permitting use in the most demanding advanced applications, such as Chemical Vapor Deposition (CVD), Atomic Layer Deposition (ALD), semiconductor processes, and lyophilization.

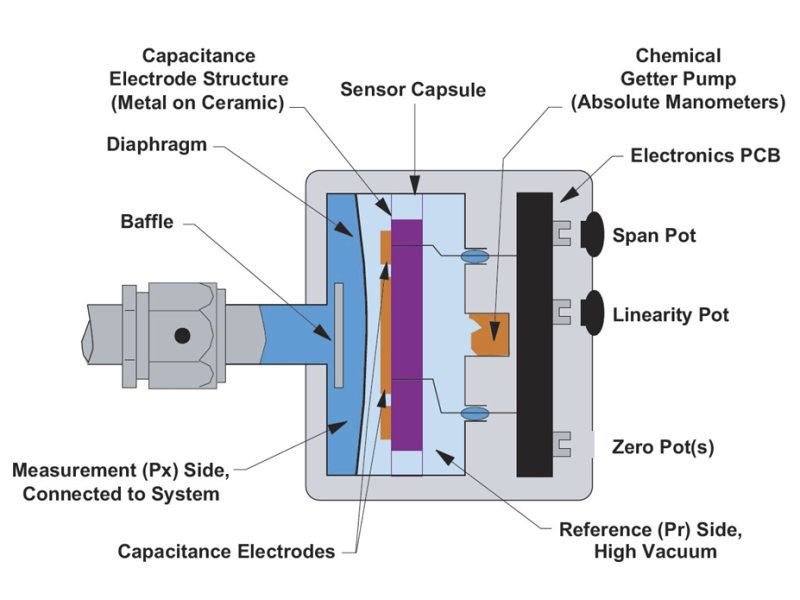

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Resources

Literature

- DA03B Heated Baratron® Manometer with EtherCAT® (2.2 MB, PDF)

Manuals

- DA03B Manometer Manual (1.7 MB, PDF)

Drawings & CADs

- DA03B Capacitance Manometer Dimensional Drawing (654.4 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity