MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

52C Baratron® Flow-through Absolute Pressure Switches

Overview

The 52C Flow-through Pressure Switch offers accurate and reliable protection vacuum/pressure processes. Designed for applications where a DC signal output is not required, these switches provide relay outputs that are readily interfaced with alarms, valve actuators, computers, process controllers, load locks and other protection devices. The 52C is referenced to vacuum.

- Flow-through configuration referenced to vacuum

- Superb set point accuracy and low hysteresis

- All-metal, all-welded construction exposing only stainless steel and Inconel® for corrosion resistance

- Switch relay can be set to energize above or below set point for fail-safe operation

- High reliability reduces downtime

Products

Configuration Options

The following options are available for the 52C Baratron® Flow-through Pressure Switch.

Ordering Code Example: 52C11TCA1AA005

| Configuration Option | Option Code |

|---|---|

| 52C Flow-through Pressure Switch | 52C |

Full Scale Ranges Available (Contact Applications Engineering for other engineering units) |

|

| 1000 Torr | 13T |

| 20 psi | 21P |

| 50 psi | 51P |

| 100 psi | 12P |

| 250 psi | RDP |

| 500 psi | 52P |

Fittings |

|

| 4 VCR fixed male | CH |

Input Voltage |

|

| 10-20 VDC | 1 |

| 20-30 VDC | 2 |

Relay Mode |

|

| Energizes with pressure above the set point | A |

| Energizes with pressure below the set point | B |

Connector |

|

| 9-pin Type "D" male | A |

| Flying leads - 2 ft. shielded cable | F |

Trip Point |

|

| Three digit value (in same units as Full Scale ranges) | xxx |

Specifications

-

TypeVacuum/pressure Switch

-

ConfigurationFlow-through

-

Pressure Range Full Scale10 Torr through 500 psi

-

Fitting Type4 VCR® male

-

Accuracy±0.5% of Full Scale (± temperature coefficient)

-

Trip Point Range5-100% of Full Scale

-

Trip Point Dead Band±3% of Full Scale

-

Response Time<20 msec

-

Internal Volume6.6 cc

-

Temperature Coefficient±0.07% of Full Scale/°C

-

Materials Exposed to Process GasesInconel and 316L stainless steel

-

Overpressure2 x Full Scale or 45 psia, whichever is greater

-

Power Requirements10-20 VDC @ 35 mA max. or 20-30 VDC @ 30 mA max

-

Ambient Operating TemperatureElectromechanical relay - SPDT (isolated) contacts rated up to 1 Amp @ 30 VDC resistive

-

ComplianceCE, UL recognized* (cULus E520864), EN/IEC CB Approved to all National Deviations *standard MKS part numbers only

Features

Baratron® Capacitance Manometer Technology

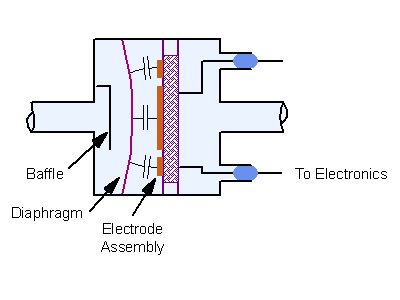

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Absolute Pressure Switching

51 and 52 pressure switches are referenced to vacuum for absolute pressure trip point switching. Applications for absolute pressure switches include soft pumping, gas box switching, and safety interlocks.

Factory Set Trip Point

The relay trip point is factory set from 5% to 100% of the Full Scale pressure range. This means there is no need for personnel to adjust the set point and no safety concerns from an erroneously adjusted set point.

Fail-Safe Relay Operation

The relay mode on 41, 42, 51, and 52 switches can be set to either energize above or below the set point. If the unit loses power, the relay switches to the Normally Closed position. The user can indicate whether the Normally Closed position is above or below the set point. Using Energize Above the set point as an example, the relay is in the Normally Open position when the pressure is higher than the trip point and Normally Closed when the pressure is below the trip point. The scenario is reversed for Energize Below the set point option. In vacuum systems, the fail-safe operation is if the system loses power causing the relay to de-energize, the relay is in the same state as the high pressure condition. Therefore, most vacuum systems require the relay energize with pressure decreasing or below the set point.

The 41B, 42B, 51B and 52B Vacuum and Atmospheric Pressure Switches provide increased accuracy over mechanical type switches, thereby providing tighter control and repeatability of process, improving throughput and yield.

9-pin Type “D” Pinouts

| Pin | Description |

|---|---|

| 1 | Power Return (-) |

| 2 | Power Input (+) |

| 3 | Relay NO Contact |

| 4 | Relay Common |

| 5 | Relay NC Contact |

| 6 | Unused |

| 7 | Unused |

| 8 | Unused |

| 9 | Chassis Ground |

Flying Lead Wiring

| Wire | Description |

|---|---|

| Red | Power Input (+) |

| Black | Power Return (-) |

| Green | Relay NO Contact |

| White | Relay Common |

| Orange | Relay NC Contact |

| Bare Wire | Chassis Ground |

Resources

Literature

- 41C, 42C, 51C, 52C Pressure Switches (2 MB, PDF)

Manuals

- MKS 41C, 42C, 51C, & 52C Pressure Switches Manual (705.4 kB, PDF)

- 41, 42, 51, 52 Vacuum/Pressure Switch Pin-outs (23.6 kB, PDF)

Drawings & CADs

- 41, 51 Baratron® Pressure/Vacuum Switch Dimensional Drawing (36.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity