MKS In-Stock Program: Over 250 products in stock and ready to ship across the United States!

370 Stabil-Ion® Hot-cathode Ionization Vacuum Gauges

Overview

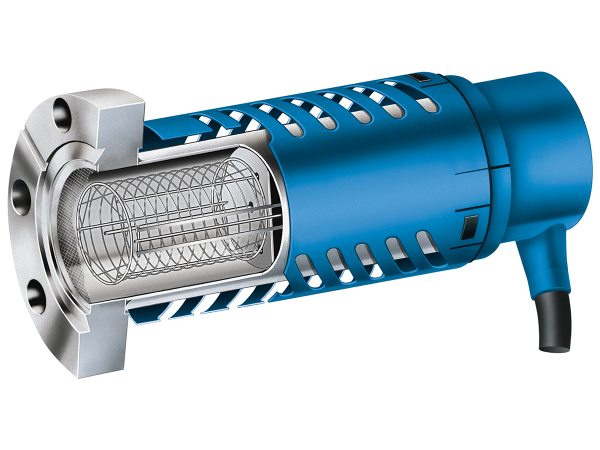

Granville-Phillips® 370 Stabil-Ion® Bayard-Alpert Vacuum Gauges are the most accurate Bayard-Alpert style hot-cathode ionization vacuum pressure gauges featuring an all metal gauge tube that eliminates glass breakage, glass decomposition, or helium permeation. A complete electrostatic shield and grounded metal gauge tube housing provide a stable electrical environment and shield against external electrical influences.

- Ionization gauge for accurate vacuum measurement from the 10-11 Torr range

- Convectron Gauge option extends pressure measurement to atmosphere

- Stabil-Ion Gauge has memory module with calibration data

- Ultra-clean gauge construction allows rapid response during pumpdown

- Dual filaments increase equipment uptime

Products

Specifications

Features

The stability, accuracy, and reliability of the Stabil-Ion® Gauge are the results of many years of testing and design. Stabil-Ion Gauges are the only high vacuum process control gauges that are designed to maintain calibration over time. Due to the design and technology of older style ionization gauges, the physical relationship between the grid and the filament is always changing. As a result, pressure readings are often inaccurate by 30% to 40% - sometimes even more. A patented precise design and advanced manufacturing techniques ensure that the StabilIon Gauge’s components do not shift, so you can count on accurate pressure measurements for the life of the gauge.

- Precision-Wound, Stress-Relieved Anode: Retains its original shape even after high-temperature degassing, thus reduces measurement errors. No movement of any of the internal components means no variations of actual pressure indication.

- Rugged Stainless Steel Construction: Prevents grid and filament damage during mounting, and eliminates the risk of glass breakage

- Tensioned Dual Filaments: Stay precisely positioned to maintain stability and calibration.

- Vacuum-Fired Components: Are never touched by bare hands during assembly. All manufacturing, assembly and testing are performed in a cleanroom environment, thereby preventing contamination and speeding vacuum system pumpdown.

- Calibration Memory: The Stabil-Ion Gauge is the first ionization gauge with sufficient long-term stability to justify storing calibration data in memory. Each StabilIon Gauge is provided with a memory module containing the calibration data based on 15 individually calibrated pressure values.

- Choice of Measuring Range: The Stabil-Ion Gauge is available for use in high vacuum or ultra-high vacuum ranges. See the Technical Specifications for measurement ranges.

Stabil-Ion® Vacuum Gauge Controllers

The Granville-Phillips® 370 Stabil-Ion® Vacuum Gauge Controller is a rack-mounted controller providing unmatched ionization gauge performance for the all-metal 370 Stabil-Ion® Gauge, delivering the long-term performance of a spinning rotor gauge at a fraction of the cost using calibration on a chip.

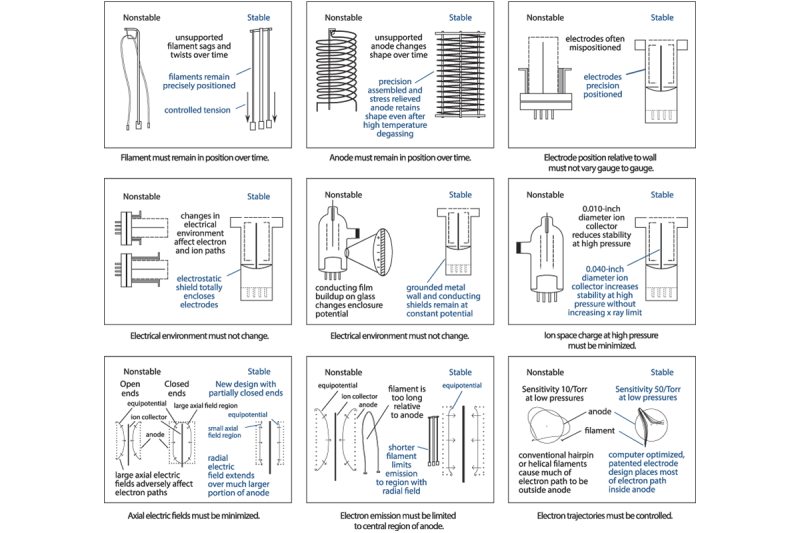

Causes of Unstable Behavior of Typical B-A Gauges vs. Stable Behavior of Stabil-Ion® Gauges

Long-term, accurate measurement is assured by the unique design and careful manufacturing of the Stabil-Ion Gauges. Here are the more important problems with older BA gauge designs that we removed in order to achieve accuracy over time and gauge-to-gauge. Sophisticated computer simulations of electron and ion trajectories helped greatly in identifying the causes of nonstable behavior

Accessories

Resources

Literature

- Vacuum Measurement Product Guide (711.5 kB, PDF)

- 370 Stabil-Ion® Vacuum Gauge and Controller (458 kB, PDF)

Manuals

- 370 Stabil-Ion® Controller Vacuum Measurement System Manual (1.7 MB, PDF)

- 370 Stabil-Ion® Gauge Controller with RS-485 Interface Option (333.1 kB, PDF)

- 370 Stabil-Ion® Gauge Installed Internal to Vacuum Chamber (427.6 kB, PDF)

Technical Papers

- Introduction to Bayard-Alpert Ionization Gauges (247 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity